Description

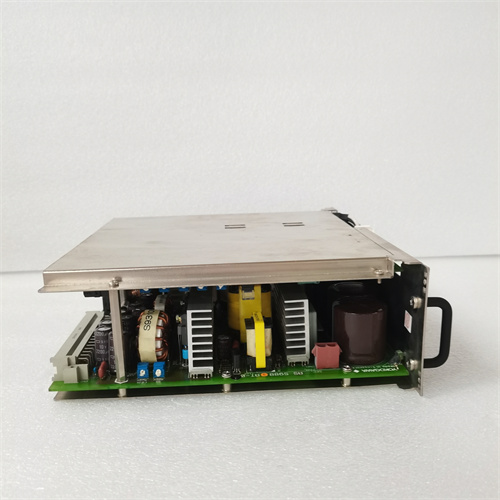

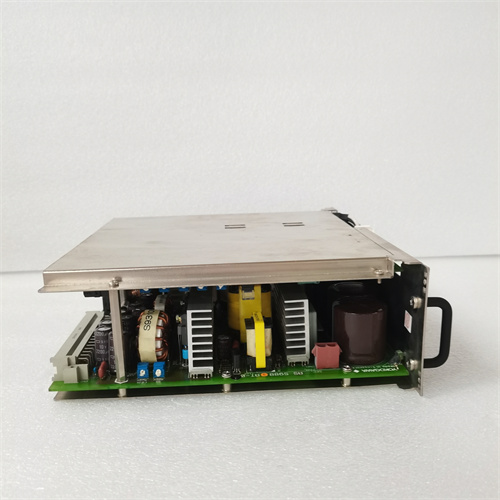

Product Description: Controller or Transmitter YOKOGAWA DR1030B60

The YOKOGAWA DR1030B60 is a sophisticated electronic controller or process transmitter from Yokogawa’s extensive product line, likely belonging to a family of indicating controllers, such as the UTAdvanced or UT series, or a specialized measuring instrument. This specific model number indicates a precise configuration designed for closed-loop control, process indication, or signal transmission of a critical process variable. The YOKOGAWA DR1030B60 integrates measurement, control logic, and human-machine interface into a single, compact unit, providing a powerful standalone or distributed control solution. For complete technical data and application manuals, visit the product page: YOKOGAWA DR1030B60. Deploying the YOKOGAWA DR1030B60 brings high reliability and precise regulation to individual control loops or critical monitoring points.

Key Parameters

- Core Function: Standalone Loop Controller / Programmable Indicator Controller. It typically performs PID control, ON/OFF control, or acts as a sophisticated signal conditioner/transmitter with a large digital display.

- Input Signal: Accepts a wide range of process inputs, as defined by its model suffix. “DR1030” suggests a platform, while “B60” is a configuration code that likely specifies the input type (e.g., thermocouple Type B, RTD, 4-20 mA, DC voltage) and potentially the number of inputs.

- Control Output: Provides one or more control outputs, which could be relay contacts, logic outputs, or continuous analog outputs (4-20 mA, SSR drive) for operating valves, heaters, or other final control elements.

- Display and Interface: Features a prominent, multi-digit, multi-line digital display (often vacuum fluorescent or high-brightness LED) for showing process variable (PV), setpoint (SP), and output value. Includes a local keypad for configuration, setpoint adjustment, and manual control.

- Control Algorithms: Employs advanced, tunable PID algorithms with features like auto-tuning, two-position control, cascade control, or program control for ramp/soak profiles.

- Communications: May include a serial communication port (e.g., RS-485) supporting protocols like Modbus RTU for integration into a DCS, PLC, or SCADA system for remote monitoring and supervision.

Advantages and Features

The main advantage of the YOKOGAWA DR1030B60 is its combination of high visibility, autonomous control capability, and Yokogawa’s renowned measurement accuracy in a single-device architecture. It eliminates the need for separate indicators, controllers, and transmitters, reducing panel space, wiring complexity, and points of failure. Its robust design ensures stable operation in harsh industrial environments with electrical noise and vibration. The intuitive local interface allows operators to monitor and intervene directly at the process point, while its communication capability enables seamless integration into plant-wide control strategies. For critical loops requiring independent, fail-operational control, the YOKOGAWA DR1030B60 is an ideal, self-contained solution.

Application Case Studies in Various Fields

- Industrial Furnace and Oven Control: Precisely regulating the temperature of a heat treatment furnace, kiln, or dryer using a thermocouple input and a solid-state relay (SSR) output for heater control.

- Machine Local Control Panels: Serving as the main temperature or pressure controller on a plastic molding machine, packaging machine, or extruder, providing local setpoint adjustment and status display for operators.

- Utility and Skid-Mounted Systems: Controlling critical parameters like jacket temperature on a reactor skid, pressure in a compressor package, or level in a local tank, functioning independently or as part of a larger system.

- Energy Management: Monitoring and controlling steam flow or temperature in a heat exchange application to optimize energy usage.

- Batch Process Sequencing: Executing a time-temperature profile for a batch reactor or cooker in facilities where a full DCS is not justified.

Comparison with Competing Products

The YOKOGAWA DR1030B60 competes directly with panel-mounted digital controllers from other leading industrial automation suppliers such as Omron (ESCN/ESCC), Honeywell (UDC), ABB (PxT/TZIDC), and Azbil (formerly Yamatake). Its key differentiators are Yokogawa’s core strength in precise measurement and sensor technology, which translates into superior input accuracy and stability. The YOKOGAWA DR1030B60 often features a very user-friendly interface and robust construction. Compared to a PLC-based solution for a single loop, it offers faster setup, dedicated controls expertise, and a local operator interface without additional hardware.

Selection Suggestions and Important Precautions

- Decode the Model Suffix Exactly: The performance of the YOKOGAWA DR1030B60 is defined by the “B60” configuration. Consult the manufacturer’s selection guide to confirm the exact input type, output type, power supply, and any special functions (e.g., alarms, communications) this specific code provides.

- Match Sensor and Actuator Specifications: Ensure the module’s input range matches your sensor (TC type, RTD, etc.) and that its output type (relay, SSR drive, current) is compatible with your final control element (contactor, valve positioner).

- Consider the Operating Environment: Verify the controller’s front-panel IP rating is suitable for its mounting location (e.g., NEMA 4X for washdown areas). Ensure ambient temperature is within its operating range.

- Plan for Configuration and Calibration: While often featuring auto-tuning, optimal performance of the YOKOGAWA DR1030B60 requires proper initial PID tuning and may require sensor calibration input. Ensure personnel are trained on its programming menus.

- Implement Redundant Safety for Critical Loops: For loops where controller failure is hazardous, do not rely solely on the YOKOGAWA DR1030B60. Implement independent safety devices (e.g., safety relays, pressure switches). Always use the correct fuse or circuit breaker on the power supply input. Purchase only from authorized distributors to ensure genuine firmware and calibration. Document all configuration settings for future reference.

IC3600STKP1 GE PLC

IC3600STKA1 GE

IC3600SVDB1 GE

IC3600AIAD1 GE

IC3600STKK1 GE PLC

IS2020ISUCG3A GE PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922