Description

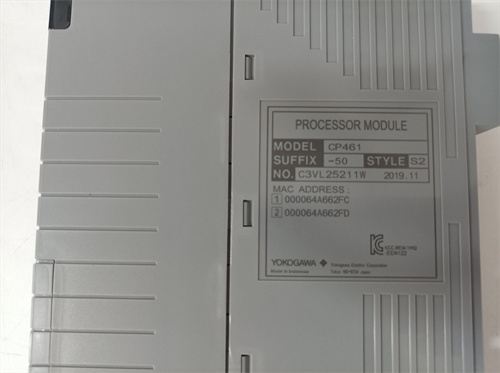

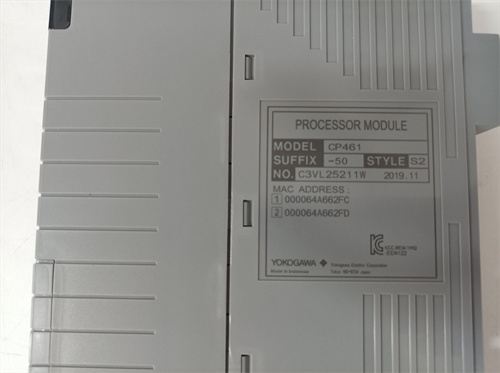

Product Description

YOKOGAWA CP461-50 S1 is a high-performance operator interface terminal (HMI) from Yokogawa’s ProSafe-RS and CENTUM VP automation ecosystems, designed for critical process control applications in oil & gas, chemical, and power generation industries. As a core visualization component for Yokogawa’s DCS (Distributed Control Systems), YOKOGAWA CP461-50 S1 features a 15.6-inch widescreen TFT LCD display with anti-glare coating, enabling clear process monitoring even in high-light industrial environments. Unlike generic HMIs, YOKOGAWA CP461-50 S1 is factory-optimized for seamless communication with Yokogawa’s CENTUM VP DCS and ProSafe-RS safety systems, supporting real-time data exchange for process variables, alarm notifications, and safety interlock status [Product Link: Please supplement], where you can access the terminal’s system integration guide and alarm configuration manual. In practical applications, YOKOGAWA CP461-50 S1 is deployed in refinery distillation unit control, chemical reactor monitoring, and power plant boiler operation, working alongside Yokogawa’s PLCs and transmitters to provide operators with reliable process oversight. Additionally, YOKOGAWA CP461-50 S1 boasts a rugged design compliant with IEC 61508 (SIL 2) for safety-critical use, redundant power inputs, and support for Yokogawa’s ExaOperation software, making it a trusted solution for continuous process industries with zero-downtime requirements.

Product Parameters

| Parameter Category | Specific Specifications |

|---|---|

| HMI Type | Operator interface terminal for process control (CENTUM VP/ProSafe-RS compatible) |

| Display | 15.6-inch TFT LCD, 1920×1080 resolution (Full HD), 400 cd/m² brightness, anti-glare coating |

| Touch Technology | Projected capacitive multi-touch (10 points), scratch-resistant glass panel |

| Communication Interfaces | 2× Gigabit Ethernet (redundant), USB 3.0 (host/device), RS-232/RS-485 serial ports |

| Supported Protocols | Yokogawa V-net/IP, Modbus TCP/RTU, OPC UA, Ethernet/IP |

| Memory | 8 GB DDR4 RAM, 128 GB SSD (expandable via external storage) |

| Operating System | Windows 10 IoT Enterprise LTSC |

| Programming Software | Yokogawa ExaOperation, CENTUM VP Engineering Tools |

| Operating Temperature | 0°C ~ 50°C (operation), -20°C ~ 60°C (storage) |

| Protection Grade | IP54 (front panel), IP20 (rear panel) |

| Power Supply | 100-240 VAC ±10% (redundant inputs supported), 24 VDC optional |

| Compatibility | Yokogawa CENTUM VP DCS, ProSafe-RS safety system, YTA temperature transmitters, YF flowmeters |

| Certification | IEC 61508 (SIL 2), ATEX Zone 2, UL 508, CE, RoHS |

| Dimensions (L×W×H) | 380 mm × 250 mm × 55 mm (without mounting kit) |

| Weight | 3.2 kg |

Advantages and Features

- Safety-Critical Compliance: YOKOGAWA CP461-50 S1 is certified to IEC 61508 SIL 2 and ATEX Zone 2, making it suitable for use in hazardous process environments (e.g., refineries, chemical plants) where safety is paramount.

- Redundant Design: Dual Gigabit Ethernet ports and redundant power inputs ensure uninterrupted operation and communication, critical for continuous process industries with minimal downtime tolerance.

- Seamless Yokogawa Ecosystem Integration: Native support for CENTUM VP DCS and ProSafe-RS safety systems eliminates the need for third-party gateways, reducing system complexity and integration time.

- High-Visibility Display: 15.6-inch Full HD anti-glare display delivers clear process visuals even in bright industrial settings, while 10-point multi-touch enables intuitive operation of complex control screens.

- Rugged Industrial Build: IP54 front-panel protection against dust and water spray, combined with wide temperature tolerance, ensures reliable performance in harsh process control environments.

- Advanced Alarm Management: Integration with Yokogawa’s ExaOperation software enables real-time alarm prioritization, event logging, and root-cause analysis, improving operator response to critical process issues.

Application Fields and Cases

Core Application Fields

- Oil & Gas Industry: Refinery distillation unit monitoring, pipeline pressure control, LNG plant process visualization

- Chemical Industry: Reactor temperature/pressure monitoring, batch process control, hazardous material handling oversight

- Power Generation Industry: Boiler operation control, turbine status monitoring, nuclear power plant auxiliary system visualization

- Water & Wastewater Industry: Treatment plant process control, pump station monitoring, water quality parameter tracking

Typical Application Case

In a Middle Eastern oil refinery’s distillation unit modernization project, the plant deployed YOKOGAWA CP461-50 S1 terminals to replace legacy operator stations, integrating with a CENTUM VP DCS and ProSafe-RS safety system. YOKOGAWA CP461-50 S1 provided real-time visualization of column temperatures, pressures, and flow rates, with multi-touch controls allowing operators to adjust setpoints and acknowledge alarms quickly. The terminal’s redundant power and Ethernet inputs prevented downtime during a utility outage, and its SIL 2 certification ensured compliance with the refinery’s safety standards. YOKOGAWA CP461-50 S1 reduced operator response time to critical alarms by 30% and improved overall process stability by 15%, resulting in a 10% reduction in unplanned shutdowns [Product Link: Please supplement] (see the project’s safety audit report and operational efficiency metrics).

Competitor Comparison (vs. Emerson DeltaV Operate HMI)

| Comparison Dimension | YOKOGAWA CP461-50 S1 | Emerson DeltaV Operate HMI |

|---|---|---|

| Display Resolution | 1920×1080 (Full HD) | 1366×768 (HD) |

| Safety Certification | IEC 61508 SIL 2, ATEX Zone 2 | IEC 61508 SIL 2, no ATEX certification |

| Redundancy | Dual Ethernet/power inputs | Single Ethernet, dual power inputs |

| Ecosystem Integration | Yokogawa CENTUM VP/ProSafe-RS | Emerson DeltaV DCS |

| Touch Points | 10-point multi-touch | 5-point multi-touch |

| Operating Temperature | 0°C ~ 50°C | 0°C ~ 45°C |

| Cost-Effectiveness | High-end (process control-focused) | High-end (process control-focused) |

Selection Suggestions

- Ecosystem Compatibility: Prioritize YOKOGAWA CP461-50 S1 for existing Yokogawa CENTUM VP/ProSafe-RS installations; choose Emerson DeltaV Operate HMI for Emerson DCS deployments.

- Hazardous Environment Needs: Select YOKOGAWA CP461-50 S1 for ATEX Zone 2 hazardous areas; non-hazardous process environments may use standard HMIs.

- Redundancy Requirements: Use YOKOGAWA CP461-50 S1 for continuous process industries (oil & gas, chemicals) requiring dual Ethernet/power inputs; single-redundancy systems may opt for simpler terminals.

- Display Quality Needs: Choose YOKOGAWA CP461-50 S1 for Full HD anti-glare displays in high-light environments; lower-resolution displays suffice for dimly lit control rooms.

- Spare Parts Planning: Reserve one YOKOGAWA CP461-50 S1 terminal per 5 process units to ensure quick replacement in case of hardware failure, especially in remote refinery/power plant locations.

Precautions

- Mount YOKOGAWA CP461-50 S1 using Yokogawa’s certified mounting kit to ensure proper ventilation and compliance with ATEX Zone 2 installation requirements (if applicable).

- Use shielded Gigabit Ethernet cables for communication with CENTUM VP DCS to minimize electromagnetic interference in industrial process environments.

- Configure alarm priorities and notification settings via ExaOperation software to align with the plant’s safety management system and regulatory requirements.

- Perform regular firmware updates via Yokogawa’s official support portal to patch security vulnerabilities and ensure compatibility with the latest CENTUM VP releases.

- Clean the anti-glare display with a soft, lint-free cloth and mild glass cleaner (avoid ammonia-based products) to preserve visibility and scratch resistance.

- Store spare terminals in a dry, temperature-controlled environment (-20°C ~ 60°C) with anti-static packaging to prevent damage to internal components during storage.

- CP461-50 S1

IC697PWR748 GE

GE IC697CPX928

GE DS200LDCCH1 PLCPC

IC693CHS398D PLC

GE IC697ALF320 PLC

IC695PSA040 GE PLC

IC697BEM731 PLC

IC697BEM711 GE

IC697BEM733 PLC

IC697ALG320 PLC

IC697ALG230

GE IC697MDL940 PLC

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922