Description

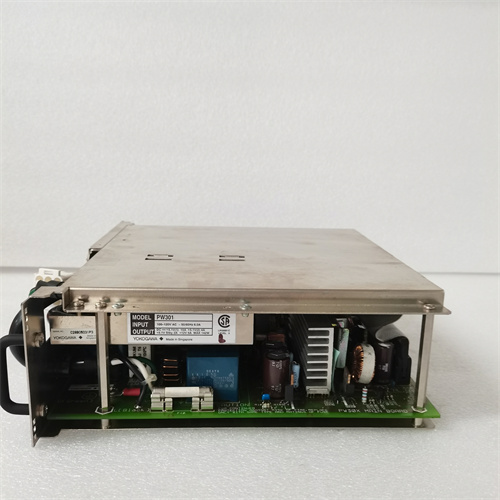

- AIP830-101

1. Product Overview

YOKOGAWA AIP830-101 is a high-performance power supply module designed for Yokogawa’s CENTUM VP distributed control system (DCS) I/O racks, engineered to deliver stable, redundant power to I/O modules and ensure uninterrupted operation of critical process control systems. As a core infrastructure component of the CENTUM VP ecosystem, YOKOGAWA AIP830-101 provides 24 VDC output with high efficiency, overload protection, and hot-swappable capability—ideal for applications in oil & gas refineries, chemical plants, power generation facilities, and water treatment plants. In a large-scale petrochemical complex, YOKOGAWA AIP830-101 supplies redundant power to I/O racks monitoring reactor processes; in a nuclear power plant auxiliary system, YOKOGAWA AIP830-101 ensures reliable power to safety-related I/O modules. Additionally, YOKOGAWA AIP830-101 features built-in diagnostics and alarm functions to alert operators of power anomalies, minimizing the risk of system downtime.

2. Product Parameters

2.1 Core Power Specifications

- Input Voltage: 100–240 VAC (50/60 Hz), 120–300 VDC (optional)

- Output Voltage: 24 VDC ±1% (regulated)

- Output Current: 10 A (continuous), 15 A (peak for 10 seconds)

- Power Output: 240 W (continuous)

- Efficiency: ≥90% (at full load)

- Redundancy Support: 1+1 hot standby configuration (parallel operation with redundant modules)

2.2 Electrical Protection Features

- Overload Protection: 150% of rated current (automatic recovery after fault clearance)

- Overvoltage Protection: 28 VDC (latch-off, manual reset)

- Short-Circuit Protection: Current-limiting (automatic recovery after short-circuit removal)

- Input Surge Protection: IEC 61000-4-5 compliant (2 kV for AC input)

- Isolation: 3000 VAC between input and output, 1500 VAC between output and chassis

2.3 Environmental & Mechanical Parameters

- Operating Temperature: 0°C to +55°C

- Storage Temperature: -20°C to +70°C

- Relative Humidity: 5%–95% (non-condensing, no dew formation)

- Protection Rating: IP20 (rack-mounted)

- Dimensions: 100 mm × 260 mm × 45 mm (L×W×H)

- Mounting: Yokogawa CENTUM VP S2 I/O racks (7-slot or 14-slot)

2.4 Certification & Compatibility

- Certifications: CE, UL 61010-1, ATEX II 2G Ex ib IIC T4, IECEx, IEC 61508 (SIL 2)

- Compatible Systems: Yokogawa CENTUM VP I/O modules (AAI141, AAI143, AIP171, AIP571), CENTUM VP S2 racks

- Diagnostic Features: LED status indicators (power on, overload, fault), remote alarm output (dry contact), current/voltage monitoring

- MTBF (Mean Time Between Failures): ≥100,000 hours (per MIL-HDBK-217F)

3. Advantages & Features

- Redundant Power Capability: YOKOGAWA AIP830-101 supports 1+1 hot standby configuration, ensuring continuous power supply to I/O racks even if one module fails—critical for safety-critical processes.

- High Efficiency & Reliability: With ≥90% efficiency and MTBF of 100,000+ hours, YOKOGAWA AIP830-101 minimizes energy consumption and reduces maintenance frequency, lowering total cost of ownership.

- Hot-Swappable Design: YOKOGAWA AIP830-101 can be replaced or installed while the I/O rack is operational, eliminating downtime for power module maintenance and improving system availability.

- Comprehensive Protection: Built-in overload, overvoltage, and short-circuit protection safeguards YOKOGAWA AIP830-101 and connected I/O modules from electrical faults, preventing damage and system disruptions.

- Advanced Diagnostics: LED indicators and remote alarm outputs provide real-time status of YOKOGAWA AIP830-101, enabling operators to quickly identify and resolve power issues before they affect process control.

4. Application Fields & Cases

4.1 Application Fields

- Oil & Gas: Refinery I/O rack power supply, offshore platform DCS power systems, pipeline monitoring station power

- Chemical Processing: Reactor control I/O rack power, batch process system power, hazardous area I/O module power

- Power Generation: Boiler/turbine control I/O power, nuclear plant auxiliary system power, renewable energy plant DCS power

- Water Treatment: Pumping station I/O rack power, wastewater treatment process control power, desalination plant DCS power

4.2 Typical Cases

- Refinery I/O Rack Redundancy: A major oil refinery deployed YOKOGAWA AIP830-101 in 1+1 hot standby configuration for its CENTUM VP I/O racks monitoring distillation columns. When one module failed during operation, the redundant unit seamlessly took over, avoiding a process shutdown and saving $500,000 in production losses.

- Chemical Plant Hazardous Area Power: A specialty chemical manufacturer used YOKOGAWA AIP830-101 (ATEX-certified) to power I/O modules in a Zone 1 hazardous area. The module’s intrinsic safety compliance and overload protection ensured safe, reliable operation in the explosive environment.

- Power Plant Safety System Power: A combined-cycle power plant integrated YOKOGAWA AIP830-101 into its safety-related I/O racks. The module’s SIL 2 certification and redundant design met strict safety standards, ensuring uninterrupted power to emergency shutdown systems.

5. Competitor Comparison

| Parameter | YOKOGAWA AIP830-101 | Competitor X DCS Power Supply Module |

|---|---|---|

| Output Current | 10 A (continuous) | 8 A (continuous) |

| Efficiency | ≥90% | ≥85% |

| Redundancy Support | 1+1 hot standby | Cold standby only |

| MTBF | ≥100,000 hours | ≥70,000 hours |

| Hazardous Area Certification | ATEX/IECEx Zone 1 | No hazardous area certification |

| SIL Rating | SIL 2 | SIL 1 |

6. Selection Suggestions & Precautions

6.1 Selection Suggestions

- Load Matching: YOKOGAWA AIP830-101 (10 A/240 W) is ideal for medium-to-large I/O racks (8–12 modules); for smaller racks (≤6 modules), select Yokogawa AIP820-050 (5 A/120 W).

- Redundancy Needs: Choose 1+1 hot standby configuration for safety-critical applications (e.g., refineries, nuclear plants); single module configuration suffices for non-critical processes (e.g., water treatment).

- Environmental Requirements: Opt for the ATEX/IECEx-certified version of YOKOGAWA AIP830-101 for hazardous area installations; standard versions are suitable for non-hazardous control rooms.

6.2 Precautions

- Installation Guidelines: Install YOKOGAWA AIP830-101 in a well-ventilated I/O rack (temperature ≤55°C) to prevent overheating; ensure proper wiring torque (0.8 N·m for power terminals) to avoid loose connections.

- Redundancy Setup: Configure redundant YOKOGAWA AIP830-101 modules with shared output bus and load-balancing resistors (per Yokogawa guidelines) to ensure seamless failover.

- Maintenance Checks: Inspect input/output connections quarterly for corrosion or overheating; replace modules if efficiency drops below 85% or MTBF thresholds are exceeded.

- Fault Handling: Do not bypass overvoltage/overload protection features—address faults immediately (e.g., short-circuits, overloaded modules) to prevent damage to YOKOGAWA AIP830-101 and connected I/O equipment.

ICO00PWE002 GE

IC200PNB001

IC200CHS022 GE PLC

IC200ALG260 GE PLC

IC200ALG230 GE PLC

GE IC200ALG331 PLC

IC200ALG264 GE PLC

IC200ALG240 GE

IC200PBI001 GE PLC

IC200DBI001 GE PLC

IC200GBI001 GE DCS

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922