Description

Product Description

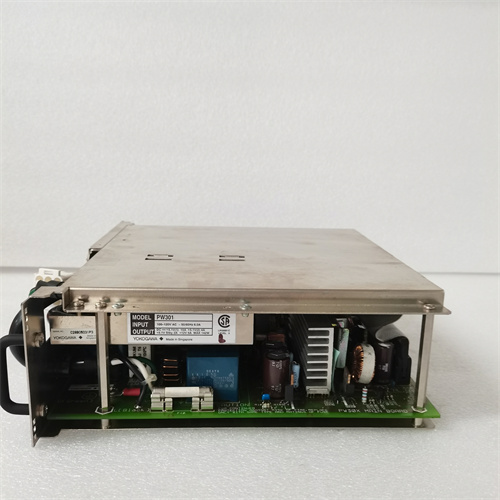

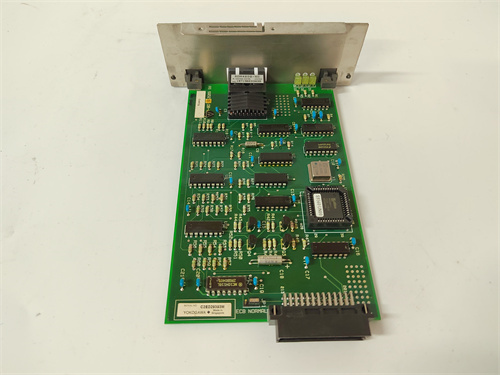

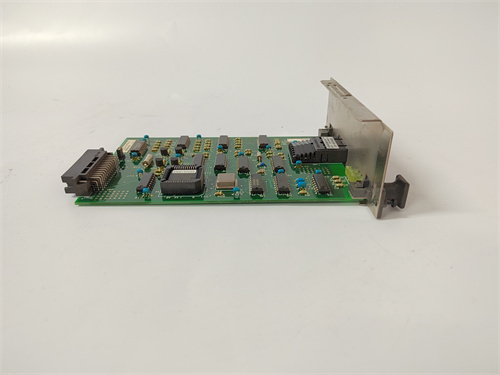

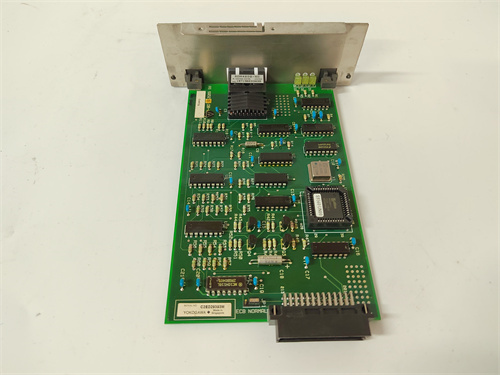

YOKOGAWA AIP578 is a high-performance Ethernet communication module for Yokogawa’s CENTUM VP DCS (Distributed Control System) and ProSafe-RS safety systems, engineered to enable seamless integration with factory-wide Ethernet networks, third-party PLCs, HMIs, and enterprise-level systems. As a core connectivity component of Yokogawa’s open automation architecture, YOKOGAWA AIP578 supports Gigabit Ethernet (1000 Mbps), standard industrial protocols (Profinet, Ethernet/IP, Modbus TCP), and Yokogawa’s proprietary V-net/IP, ensuring high-speed data exchange between the DCS and external systems. Unlike generic Ethernet modules, YOKOGAWA AIP578 is factory-optimized for CENTUM VP’s real-time process control requirements, providing deterministic communication with minimal latency for critical process data [Product Link: Please supplement], where you can access the module’s protocol configuration guide and network security manual. In practical applications, YOKOGAWA AIP578 connects CENTUM VP DCS to YOKOGAWA CP461-50 S1 HMIs, Siemens PLCs, and plant MES (Manufacturing Execution Systems), working alongside YOKOGAWA PW481-50 power supplies to maintain reliable connectivity in 24/7 process environments. Additionally, YOKOGAWA AIP578 features redundant Ethernet ports, built-in firewall capabilities, and compliance with IEC 61508 (SIL 2) for safety-critical use, making it a trusted solution for industries requiring secure, high-speed DCS-to-network integration.

Product Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Module Type | Gigabit Ethernet communication module (CENTUM VP/ProSafe-RS compatible) |

| Communication Interfaces | 2× Gigabit Ethernet ports (RJ45/SFP), 1× Fast Ethernet port (for maintenance) |

| Supported Protocols | Ethernet/IP, Profinet IO, Modbus TCP, V-net/IP, OPC UA, SNMP |

| Data Transfer Rate | 10/100/1000 Mbps (auto-negotiation), full-duplex mode |

| Redundancy Features | Dual Ethernet ports (ring/star topology), automatic failover (<5 ms) |

| Network Security | Built-in firewall, IP filtering, HTTPS/TLS encryption, 802.1X authentication |

| Operating Temperature | 0°C ~ 55°C (operation), -20°C ~ 70°C (storage) |

| Protection Grade | IP20 (rack mounting) |

| Power Supply | 24 VDC (from CENTUM VP rack power, e.g., YOKOGAWA PW481-50) |

| Compatibility | Yokogawa CENTUM VP CPU modules, ProSafe-RS safety controllers, CP461-50 S1 HMIs, third-party PLCs/HMIs |

| Certification | IEC 61508 (SIL 2), ATEX Zone 2, UL 508, CE, RoHS, FCC Part 15 |

| Dimensions (L×W×H) | 100 mm × 140 mm × 35 mm |

| Weight | 0.6 kg |

Advantages and Features

- Gigabit Ethernet Performance: YOKOGAWA AIP578 delivers 1000 Mbps full-duplex communication, enabling high-speed transfer of large process datasets (e.g., historical trends, video surveillance) between DCS and enterprise systems without latency.

- Multi-Protocol Support: Compatibility with Ethernet/IP, Profinet, Modbus TCP, and OPC UA ensures seamless integration with third-party automation equipment (Siemens, Allen-Bradley, Mitsubishi), eliminating the need for additional gateways.

- Redundant Connectivity: Dual Gigabit Ethernet ports with <5 ms failover support ring/star topologies, ensuring uninterrupted network connectivity even during cable or switch failures in critical process environments.

- Enterprise-Grade Security: Built-in firewall, encryption, and authentication features protect YOKOGAWA AIP578 and connected DCS systems from cyber threats, complying with industry standards (e.g., ISA/IEC 62443).

- Seamless CENTUM VP Integration: Pre-configured for Yokogawa’s DCS, the module auto-detects V-net/IP devices and integrates with CENTUM VP’s engineering tools, reducing setup time by 30% compared to generic Ethernet modules.

- Safety-Critical Compliance: IEC 61508 SIL 2 and ATEX Zone 2 certifications make YOKOGAWA AIP578 suitable for hazardous process environments (refineries, chemical plants) where secure, reliable communication is non-negotiable.

Application Fields and Cases

Core Application Fields

- Oil & Gas Industry: Refinery DCS integration with enterprise MES, offshore platform DCS-to-shore communication

- Chemical Industry: Plant-wide Ethernet networking for DCS, PLCs, and safety systems, batch process data transfer to ERP

- Power Generation Industry: Thermal power plant DCS connection to turbine control systems, grid monitoring data transmission

- Pharmaceutical Industry: GMP-compliant DCS-to-QMS (Quality Management System) data exchange, audit trail logging

Typical Application Case

In a European pharmaceutical manufacturer’s production facility project, the plant deployed YOKOGAWA AIP578 modules to connect CENTUM VP DCS (controlling sterile filling lines) to Siemens S7-1500 PLCs, YOKOGAWA CP461-50 S1 HMIs, and a plant-wide MES. YOKOGAWA AIP578’s Gigabit Ethernet speed enabled real-time transfer of batch production data (fill volume, temperature, pressure) to the MES, ensuring compliance with GMP regulations. The module’s redundant Ethernet ports prevented downtime during a network switch failure, and its built-in firewall protected the DCS from unauthorized access. YOKOGAWA AIP578 also supported OPC UA communication with the plant’s ERP system, enabling end-to-end visibility of production data. The module improved data transfer efficiency by 60% compared to the facility’s legacy Fast Ethernet modules and ensured 100% compliance with regulatory audit requirements [Product Link: Please supplement] (see the project’s compliance report and network performance metrics).

Competitor Comparison (vs. Emerson DeltaV Ethernet Module KJ2005X1-BA1)

| Comparison Dimension | YOKOGAWA AIP578 | Emerson DeltaV Ethernet Module KJ2005X1-BA1 |

|---|---|---|

| Data Transfer Rate | 10/100/1000 Mbps (Gigabit) | 10/100 Mbps (Fast Ethernet) |

| Redundancy Failover Time | <5 ms | <10 ms |

| Supported Protocols | Ethernet/IP, Profinet, Modbus TCP, OPC UA | Ethernet/IP, Modbus TCP (no Profinet/OPC UA) |

| Network Security | Firewall, encryption, 802.1X | Basic IP filtering only |

| Safety Certification | IEC 61508 SIL 2, ATEX Zone 2 | IEC 61508 SIL 2, no ATEX certification |

| Ecosystem Integration | Yokogawa CENTUM VP (plug-and-play) | Emerson DeltaV (manual configuration) |

| Cost-Effectiveness | Mid-range (Gigabit, multi-protocol) | Mid-range (Fast Ethernet, limited protocols) |

Selection Suggestions

- Bandwidth Requirements: Prioritize YOKOGAWA AIP578 for high-bandwidth applications (Gigabit Ethernet); choose Fast Ethernet modules for low-data-rate communication.

- Protocol Needs: Select YOKOGAWA AIP578 if Profinet or OPC UA is required; Emerson modules suffice for Ethernet/IP/Modbus-only deployments.

- Hazardous Environment Needs: Use YOKOGAWA AIP578 for ATEX Zone 2 hazardous areas; non-hazardous environments may use standard Ethernet modules.

- Security Requirements: Choose YOKOGAWA AIP578 for enterprise-grade security (firewall, encryption); basic security needs may use simpler modules.

- Ecosystem Compatibility: Opt for YOKOGAWA AIP578 for existing CENTUM VP installations; select Emerson modules for DeltaV DCS systems.

Precautions

- Configure YOKOGAWA AIP578 in ring topology with dual Ethernet ports to maximize redundancy, and connect each port to separate network switches from different vendors (if possible) to avoid single points of failure.

- Use Cat 6a shielded cables for Gigabit Ethernet connections and ground the shield at both ends to minimize electromagnetic interference in industrial environments.

- Enable firewall rules and encryption (HTTPS/TLS) via CENTUM VP engineering software to protect the module from cyber threats, and update security settings regularly.

- Test redundant failover functionality after installation by disconnecting the primary Ethernet port and verifying uninterrupted communication with external systems.

- Mount YOKOGAWA AIP578 in a well-ventilated section of the CENTUM VP rack, with minimum 5 cm clearance from adjacent modules to prevent overheating.

- Store spare modules in anti-static packaging in a dry, temperature-controlled environment (-20°C ~ 70°C) to prevent moisture or static damage to internal components.

- AIP578

IC693CP1374 PLC

IC693CP1351 PLC

IC693CPU350 GE PLC

IC670PBI001 GE PLC

IC670CHS002 PLC/PC

IC670GBI002 GE PLC

IC200CPU001 GE PLC

GE IC200PWR102 PLC

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922