Description

1. Product Overview

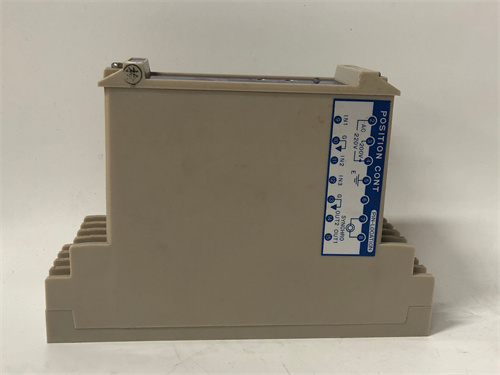

YASKAWA JGSM-12-11-S is a high-performance safety relay module from Yaskawa, engineered to monitor and control safety-critical circuits in industrial automation systems, including emergency stops, light curtains, safety gates, and two-hand control stations. As a core component of Yaskawa’s safety automation portfolio, YASKAWA JGSM-12-11-S provides reliable fail-safe protection, ensuring compliance with global safety standards (e.g., ISO 13849, IEC 62061) for machinery and robotic systems. In automotive manufacturing plants, YASKAWA JGSM-12-11-S monitors emergency stop circuits on robotic welding cells to prevent accidental machine activation; in packaging facilities, YASKAWA JGSM-12-11-S safeguards operators by interlocking safety gates with conveyor systems. Additionally, YASKAWA JGSM-12-11-S features diagnostic capabilities and modular design, making it easy to integrate into existing control systems and reducing downtime for maintenance.

2. Product Parameters

2.1 Core Safety Specifications

- Safety Category: ISO 13849-1 Category 4

- Performance Level: PL e

- SIL Rating: SIL 3 (per IEC 62061)

- Number of Safety Inputs: 4 dual-channel inputs (for emergency stop, safety gates, light curtains)

- Number of Safety Outputs: 3 normally closed (NC) safety contacts, 1 normally open (NO) auxiliary contact

- Response Time: ≤50 ms (from input signal to output switching)

2.2 Electrical Parameters

- Operating Voltage: 24 VDC ±15%

- Power Consumption: ≤5 W

- Input Current: ≤5 mA per channel (24 VDC)

- Output Contact Rating: 6 A/250 VAC (resistive load), 6 A/24 VDC (resistive load)

- Isolation: 2500 VAC between input/output circuits and power supply

- Short-Circuit Protection: Yes (output circuits)

2.3 Environmental & Mechanical Parameters

- Operating Temperature: -25°C to +55°C

- Storage Temperature: -40°C to +70°C

- Relative Humidity: 5%–95% (non-condensing)

- Protection Rating: IP20 (panel-mounted)

- Dimensions: 60 mm × 100 mm × 120 mm (L×W×H)

- Mounting: DIN rail (35 mm)

2.4 Certification & Compatibility

- Certifications: CE, UL 508, TÜV Rheinland, ISO 13849-1, IEC 62061

- Compatible Systems: Yaskawa PLCs (JAMSC series), servo drives (Σ-V/Σ-VI), robot controllers (DX200/DX300)

- Diagnostic Features: LED indicators for power, input status, output status, fault conditions

3. Advantages & Features

- Top-Tier Safety Ratings: YASKAWA JGSM-12-11-S meets ISO 13849-1 Category 4, PL e, and SIL 3 standards, providing the highest level of protection for operators and machinery in high-risk industrial environments.

- Dual-Channel Input Design: Each safety input of YASKAWA JGSM-12-11-S features dual-channel monitoring, ensuring reliable detection of faults (e.g., broken wires, short circuits) and preventing unsafe system operation.

- Fast Response Time: With a ≤50 ms response time, YASKAWA JGSM-12-11-S quickly triggers safety outputs (e.g., machine shutdown) when a hazard is detected, minimizing the risk of operator injury or equipment damage.

- Integrated Diagnostics: LED indicators and fault feedback signals from YASKAWA JGSM-12-11-S simplify troubleshooting, allowing maintenance teams to quickly identify issues (e.g., input short circuits, output contact wear) and reduce downtime.

- Modular & Compact Design: The DIN-rail mountable, compact form factor of YASKAWA JGSM-12-11-S saves panel space and enables easy integration with other automation components, ideal for retrofitting or new system installations.

4. Application Fields & Cases

4.1 Application Fields

- Industrial Robotics: Emergency stop monitoring for robot cells, safety gate interlocks

- Manufacturing: Light curtain control, two-hand control stations, conveyor safety interlocks

- Packaging: Machine guarding for filling/sealing equipment, palletizer safety circuits

- Automotive: Welding cell safety systems, assembly line emergency stop circuits

- Food & Beverage: Safety interlocks for processing machinery, packaging line guarding

4.2 Typical Cases

- Robotic Welding Cell Safety: An automotive OEM installed YASKAWA JGSM-12-11-S in robotic welding cells to monitor emergency stop buttons and safety gates. The module’s dual-channel inputs detected a broken emergency stop wire, triggering an immediate machine shutdown and preventing a potential operator injury.

- Packaging Line Guarding: A food packaging facility used YASKAWA JGSM-12-11-S to interlock safety gates with a high-speed filling line. When a gate was opened during operation, the module shut down the line within 40 ms, avoiding product spillage and operator exposure to moving parts.

- Conveyor System Safety: A logistics provider integrated YASKAWA JGSM-12-11-S into conveyor systems to monitor light curtains at loading/unloading stations. The module’s diagnostic LEDs identified a faulty light curtain sensor, allowing maintenance to replace it before a safety incident occurred.

5. Competitor Comparison

| Parameter | YASKAWA JGSM-12-11-S | Competitor X Safety Relay Module |

|---|---|---|

| Safety Category | ISO 13849-1 Cat 4 | ISO 13849-1 Cat 3 |

| Performance Level | PL e | PL d |

| Response Time | ≤50 ms | ≤100 ms |

| Input Channels | 4 dual-channel | 2 dual-channel |

| Operating Temperature | -25°C to +55°C | 0°C to +50°C |

| Diagnostic Features | LED + fault feedback | LED only |

6. Selection Suggestions & Precautions

6.1 Selection Suggestions

- Safety Requirement Matching: YASKAWA JGSM-12-11-S (Cat 4/PL e/SIL 3) is ideal for high-risk applications (e.g., robotic cells, heavy machinery); for lower-risk tasks (e.g., small conveyors), select Yaskawa JGSM-08-11-S (Cat 3/PL d).

- Input/Output Needs: Verify the number of safety inputs/outputs required (4 inputs/3 outputs for YASKAWA JGSM-12-11-S); choose modules with additional channels for complex safety circuits (e.g., multiple emergency stops).

- Environmental Conditions: Select YASKAWA JGSM-12-11-S for cold-temperature environments (-25°C to +55°C); use enclosed versions for dusty or humid locations (e.g., food processing plants).

6.2 Precautions

- Wiring Guidelines: Use shielded cables for safety inputs/outputs, with shielding grounded at one end only to avoid ground loops. Wire dual-channel inputs separately to prevent common-mode faults.

- Installation Compliance: Mount YASKAWA JGSM-12-11-S in a dedicated safety circuit section of the control panel, away from high-voltage equipment (e.g., contactors) to minimize EMI interference.

- Maintenance Checks: Inspect output contacts annually for wear (replace if contact resistance exceeds 100 mΩ); test safety circuits monthly to ensure YASKAWA JGSM-12-11-S triggers shutdowns correctly.

- Fault Handling: Do not bypass safety circuits or disable YASKAWA JGSM-12-11-S diagnostics—address faults immediately to maintain compliance with safety standards and prevent accidents.

- JGSM-12-11-S

PLC IC697CPM790-CC

IC697CPX935 GE

VMIVME-7671-421000 GE

IS200VSV0H1BEF

IS200VCRCH1BBC DCS

DCS IC697CPU374 GE

IC697CMM742 GE

DS200DCFBG1BLC GE

GE DS200FCGDHIBBA PLC

IC697BEM733 GE

XYCOM XVME653

IC693ACC307

IC693CPU360-BA GE

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922