Description

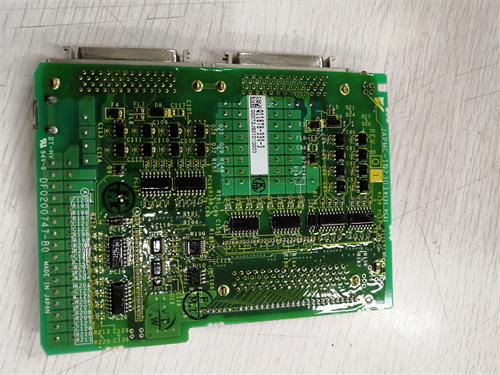

Product Description

YASKAWA JAPMC-CM2310 is a high-performance EtherCAT communication master module for Yaskawa’s MP series motion controllers (MP2000/MP3000) and PLCs, designed to enable real-time, high-speed synchronization of multi-axis servo systems in industrial automation applications. As a core component of Yaskawa’s open automation architecture, YASKAWA JAPMC-CM2310 supports EtherCAT’s distributed clock synchronization (≤1 μs jitter), enabling precise coordination of up to 64 servo axes, I/O modules, and third-party EtherCAT devices. Unlike generic EtherCAT masters, YASKAWA JAPMC-CM2310 is factory-optimized for Yaskawa Sigma-7/Sigma-5 servo drives, ensuring seamless plug-and-play integration and minimal configuration time [Product Link: Please supplement], where you can access the module’s EtherCAT network configuration guide and compatibility matrix. In practical deployments, YASKAWA JAPMC-CM2310 is used in CNC machine tool axis control, packaging machinery multi-axis synchronization, and robotic transfer line motion coordination, working alongside YASKAWA CP451-10-S2 HMIs for real-time status monitoring. Additionally, YASKAWA JAPMC-CM2310 features redundant EtherCAT ports for fault-tolerant networks, built-in diagnostic tools for network health monitoring, and compliance with international industrial standards, making it a reliable solution for high-dynamic motion control systems.

Product Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Module Type | EtherCAT communication master module (MP series controller-compatible) |

| EtherCAT Performance | Distributed clock synchronization (≤1 μs jitter), cycle time: 100 μs ~ 10 ms |

| Maximum Nodes | 64 EtherCAT slaves (servo drives, I/O modules, third-party devices) |

| Communication Interfaces | 2× EtherCAT ports (RJ45, redundant ring configuration supported), 1× Ethernet port (for HMI/PLC) |

| Supported Protocols | EtherCAT (CoE, FoE, EoE), Modbus TCP (for upper-level communication) |

| I/O Integration | Direct mapping of EtherCAT slave I/O to controller memory (no programming required) |

| Operating Temperature | 0°C ~ 55°C (operation), -20°C ~ 65°C (storage) |

| Protection Grade | IP20 (rack mounting) |

| Power Supply | 24 VDC ±10% (from controller backplane) |

| Compatibility | Yaskawa MP2000/MP3000 motion controllers, Sigma-7/Sigma-5 servo drives, EtherCAT I/O modules |

| Certification | CE, UL 508, cULus, RoHS, EN 61131-2 |

| Dimensions (L×W×H) | 100 mm × 140 mm × 35 mm |

| Weight | 0.4 kg |

Advantages and Features

- High-Precision EtherCAT Synchronization: YASKAWA JAPMC-CM2310 delivers ≤1 μs clock jitter, enabling sub-millisecond coordination of multi-axis servo systems—critical for high-speed, high-accuracy applications like CNC machining and semiconductor manufacturing.

- Redundant EtherCAT Networks: Dual EtherCAT ports support ring topology configurations, ensuring uninterrupted communication if a network segment fails, which is essential for 24/7 production environments.

- Seamless Yaskawa Ecosystem Integration: Pre-calibrated for Sigma-7/Sigma-5 servo drives, YASKAWA JAPMC-CM2310 eliminates manual parameter tuning and reduces integration time by up to 40% compared to generic EtherCAT masters.

- Built-In Diagnostics: Real-time monitoring of EtherCAT network status, slave device health, and communication errors provides early warnings of potential failures, minimizing unplanned downtime.

- Open Protocol Support: Compatibility with CoE (CANopen over EtherCAT), FoE (File access over EtherCAT), and EoE (Ethernet over EtherCAT) enables integration with third-party sensors, actuators, and I/O modules.

- Compact Design: The module’s space-saving form factor fits into standard Yaskawa controller racks, maximizing flexibility for small-footprint automation systems (e.g., desktop CNC machines).

Application Fields and Cases

Core Application Fields

- Machine Tool Industry: Multi-axis CNC milling machine synchronization, lathe spindle/feed axis coordination

- Packaging Industry: High-speed labeling machine axis control, carton forming machine motion synchronization

- Semiconductor Industry: Wafer transfer robot multi-axis control, lithography equipment precision positioning

- Automotive Industry: Assembly line conveyor-servo synchronization, welding robot position control

Typical Application Case

In a Swiss precision machining company’s 5-axis CNC mill upgrade project, the plant integrated YASKAWA JAPMC-CM2310 with an MP3000 motion controller and six Sigma-7 servo drives to replace an aging analog control system. YASKAWA JAPMC-CM2310’s EtherCAT synchronization enabled 5-axis coordination with ±5 μm positioning accuracy, improving part quality by 25% and reducing cycle time by 15%. The module’s redundant EtherCAT ports prevented production downtime during a network cable failure, and its built-in diagnostics alerted maintenance teams to a failing servo drive before it caused a fault. YASKAWA JAPMC-CM2310 also simplified integration with the plant’s existing YASKAWA CP451-10-S2 HMI, providing real-time axis status and error alerts to operators [Product Link: Please supplement] (see the project’s precision test data and production efficiency report).

Competitor Comparison (vs. Beckhoff EL6692 EtherCAT Master Module)

| Comparison Dimension | YASKAWA JAPMC-CM2310 | Beckhoff EL6692 EtherCAT Master Module |

|---|---|---|

| Synchronization Jitter | ≤1 μs | ≤2 μs |

| Redundant Ports | 2× EtherCAT (ring topology) | 1× EtherCAT (no redundancy) |

| Ecosystem Integration | Yaskawa Sigma-7/Sigma-5 drives (plug-and-play) | Generic (manual configuration required) |

| Maximum Nodes | 64 | 128 |

| Controller Compatibility | Yaskawa MP series only | Beckhoff CX series + third-party PLCs |

| Operating Temperature | 0°C ~ 55°C | -25°C ~ 60°C |

| Cost-Effectiveness | Mid-range (Yaskawa-optimized) | Mid-range (generic open architecture) |

Selection Suggestions

- Motion Controller Compatibility: Prioritize YASKAWA JAPMC-CM2310 for Yaskawa MP2000/MP3000 controllers; choose Beckhoff EL6692 for Beckhoff CX series or third-party PLCs.

- Redundancy Needs: Select YASKAWA JAPMC-CM2310 for critical applications requiring fault-tolerant EtherCAT networks; non-redundant systems may use single-port modules.

- Precision Requirements: Use YASKAWA JAPMC-CM2310 for applications needing ≤1 μs synchronization jitter (e.g., CNC machining); lower-precision tasks may use cost-effective alternatives.

- Ecosystem Alignment: Choose YASKAWA JAPMC-CM2310 if using Yaskawa servo drives to leverage plug-and-play integration; generic modules are better for mixed-vendor systems.

- Spare Parts Planning: Reserve one YASKAWA JAPMC-CM2310 module per 4 production lines to ensure quick replacement in case of network master failure.

Precautions

- Configure the EtherCAT network in Yaskawa’s MotionWorks IEC software, using the module’s built-in distributed clock function to synchronize all slave devices (servo drives/I/O).

- Use shielded twisted-pair EtherCAT cables (Cat 5e or higher) and ground the shield at both ends to minimize electromagnetic interference in high-noise environments (e.g., near motors or inverters).

- Test redundant ring topology functionality after installation by disconnecting a network cable to verify that communication switches to the backup path without interruption.

- Update the module’s firmware via the MP controller’s maintenance interface to ensure compatibility with the latest Sigma-7 servo drive firmware versions.

- Mount YASKAWA JAPMC-CM2310 in a well-ventilated section of the controller rack to avoid overheating, especially in high-temperature industrial environments.

- Store spare modules in anti-static packaging in a dry, temperature-controlled environment (-20°C ~ 65°C) to prevent static discharge or moisture damage to internal components.

- JAPMC-CM2310

IC693BEM331K GE DCS

GE IC693CP1364 PC

IC693PBS201 PC

HE693PBS105G

HE693PBM101F GE DCS

HE693PBM101E DCS

IC693MDL740F

IC695CPU310-GV DCS

IC693CPU374 GE PLC

IC693CPU315 GE

GE IC697CPM925 DCS

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922