Description

1. Product Overview

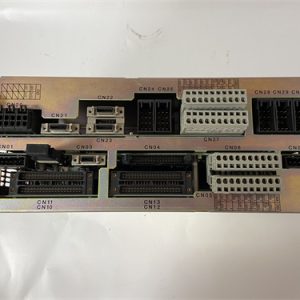

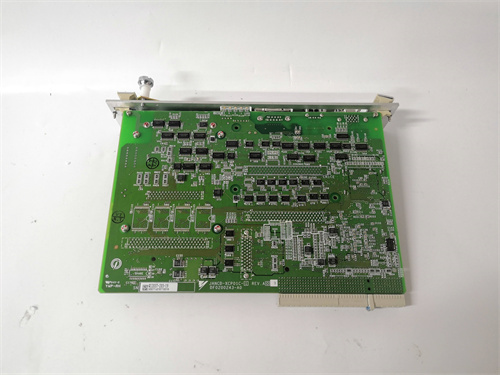

YASKAWA JANCD-JMM01-1 is a high-performance motion control module designed for Yaskawa’s JZRCR and JANCD series robot controllers, engineered to manage precise motor drive signals, axis synchronization, and real-time motion commands for industrial robots and automated machinery. As a critical interface between the robot CPU and servo drives, YASKAWA JANCD-JMM01-1 enables high-speed, high-accuracy positioning of robot arms, conveyors, and linear motion systems—essential for applications like automotive welding, electronics assembly, and material handling. In automotive manufacturing plants, YASKAWA JANCD-JMM01-1 synchronizes multi-axis robot movements for precise body-in-white welding; in semiconductor fabrication facilities, YASKAWA JANCD-JMM01-1 controls wafer-handling robot motion with micron-level precision. Additionally, YASKAWA JANCD-JMM01-1 supports diagnostic and safety features to minimize downtime and ensure compliance with industrial safety standards.

2. Product Parameters

2.1 Core Motion Control Specifications

- Number of Controlled Axes: 6 axes (robot joints) + 2 external axes (conveyors/positioners)

- Positioning Accuracy: ±0.01 mm (for linear axes), ±0.001° (for rotary axes)

- Motion Command Interface: Pulse/direction, analog torque control, EtherCAT (real-time communication)

- Maximum Input Frequency: 1 MHz (pulse signals)

- Servo Drive Compatibility: Yaskawa Σ-V/Σ-VI series servo drives

- Cycle Time: 1 ms (real-time motion processing)

2.2 Electrical Parameters

- Power Supply: 24 VDC ±10% (logic power), 200–240 VAC (servo power interface)

- Power Consumption: ≤15 W (logic), ≤5 W (signal interfaces)

- Input/Output Signals: 16 digital inputs (24 VDC), 16 digital outputs (24 VDC, 0.5 A), 4 analog inputs (0–10 V)

- Isolation: 2500 VAC between control circuits and power circuits; 1500 VAC between axes

- Communication Protocols: EtherCAT, RS-232, Modbus RTU

2.3 Environmental & Mechanical Parameters

- Operating Temperature: 0°C to +55°C

- Storage Temperature: -20°C to +70°C

- Relative Humidity: 5%–95% (non-condensing)

- Protection Rating: IP20 (panel-mounted in control cabinet)

- Dimensions: 180 mm × 120 mm × 80 mm (L×W×H)

- Mounting: DIN rail (35 mm) or panel mounting via screws

2.4 Certification & Compatibility

- Certifications: CE, UL 508, ISO 13849-1 (Safety Category 3), IEC 61508 (SIL 2)

- Compatible Systems: Yaskawa DX200/DX300 robot controllers, Σ-V/Σ-VI servo drives, MotoSim EG-VRC simulation software

- Safety Features: Emergency stop, overtravel protection, servo error detection

3. Advantages & Features

- High-Accuracy Motion Control: YASKAWA JANCD-JMM01-1’s 1 ms cycle time and advanced servo control algorithms enable micron-level positioning, critical for precision applications like electronics assembly and medical device manufacturing.

- Multi-Axis Synchronization: The module supports 6 robot axes + 2 external axes, allowing YASKAWA JANCD-JMM01-1 to coordinate complex movements between robots and peripheral equipment (e.g., conveyors, positioners) for seamless production workflows.

- Real-Time Communication: EtherCAT integration in YASKAWA JANCD-JMM01-1 ensures low-latency data transfer between the module and servo drives, enabling high-speed motion responses and reducing cycle times by up to 20%.

- Built-In Diagnostics: YASKAWA JANCD-JMM01-1 provides real-time feedback on servo status, axis position, and error codes, simplifying troubleshooting and minimizing unplanned downtime in industrial environments.

- Safety Compliance: The module meets ISO 13849-1 and IEC 61508 standards, with integrated emergency stop and overtravel protection features to ensure safe operation of YASKAWA JANCD-JMM01-1 in high-risk manufacturing settings.

4. Application Fields & Cases

4.1 Application Fields

- Industrial Robotics: Automotive welding robots, material handling robots, palletizing robots, collaborative robots (cobots)

- Automated Manufacturing: Electronics assembly lines, semiconductor wafer handling, pharmaceutical packaging machinery

- Motion Control Systems: Multi-axis linear stages, gantry robots, CNC machine tools, laser cutting systems

- Automotive Industry: Body-in-white welding, paint shop robots, component assembly stations

4.2 Typical Cases

- Automotive Welding Robot Control: A major automotive OEM integrated YASKAWA JANCD-JMM01-1 into its DX200 robot controllers for body-in-white welding robots. The module’s multi-axis synchronization enabled precise coordination of 6 robot axes and 2 conveyor axes, reducing welding cycle time by 15% and improving weld quality consistency.

- Semiconductor Wafer Handling: A semiconductor manufacturer used YASKAWA JANCD-JMM01-1 to control wafer-handling robots in cleanroom environments. The module’s ±0.01 mm positioning accuracy ensured damage-free wafer transfer, reducing production defects by 25%.

- Electronics Assembly Automation: An electronics contract manufacturer deployed YASKAWA JANCD-JMM01-1 in its surface mount technology (SMT) assembly lines. The module’s real-time EtherCAT communication enabled fast, accurate placement of microchips, increasing line throughput by 30%.

5. Competitor Comparison

| Parameter | YASKAWA JANCD-JMM01-1 | Competitor X Robot Motion Control Module |

|---|---|---|

| Controlled Axes | 6 + 2 external | 4 + 1 external |

| Positioning Accuracy | ±0.01 mm/±0.001° | ±0.05 mm/±0.01° |

| Cycle Time | 1 ms | 2 ms |

| Communication Protocol | EtherCAT + Modbus RTU | Modbus RTU only |

| Safety Certification | ISO 13849-1 Cat 3/SIL 2 | ISO 13849-1 Cat 2/SIL 1 |

| Servo Drive Compatibility | Yaskawa Σ-V/Σ-VI | Limited to proprietary drives |

6. Selection Suggestions & Precautions

6.1 Selection Suggestions

- Axis Count Requirements: YASKAWA JANCD-JMM01-1 (6+2 axes) is ideal for multi-axis robot systems; for smaller applications (≤4 axes), select Yaskawa JANCD-JMM02-1 (cost-optimized 4-axis module).

- Controller Compatibility: Verify compatibility with Yaskawa DX200/DX300 robot controllers and Σ-V/Σ-VI servo drives before installation; use MotoSim EG-VRC software for pre-deployment testing.

- Safety Needs: Choose the SIL 2/ISO 13849-1 Cat 3 configuration for high-risk applications (e.g., automotive welding); standard configurations suffice for low-risk tasks (e.g., material handling).

6.2 Precautions

- Wiring Guidelines: Use shielded twisted-pair cables for EtherCAT and servo signals, with shielding grounded at the module end only to minimize EMI. Tighten terminal screws to 0.8 N·m to prevent signal loss.

- Calibration Requirements: Calibrate YASKAWA JANCD-JMM01-1 with Yaskawa’s servo tuning software (SigmaWin+) after installation to optimize motion performance; recalibrate after mechanical modifications (e.g., robot arm replacement).

- Environmental Protection: Mount YASKAWA JANCD-JMM01-1 in a sealed control cabinet to protect against dust and moisture; ensure cabinet temperature remains within 0°C to +55°C to avoid overheating.

- Safety Interlocks: Connect emergency stop circuits directly to YASKAWA JANCD-JMM01-1’s dedicated safety inputs (not via PLC) to ensure compliance with ISO 13849-1 standards and fast emergency response.

- JANCD-JMM01-1

DS200DCFBG1BCC

VMIVME-7614-132 GE DCS

IC697ALG320

IC697MDL653 GE DCS

IC697PWR711B GE DCS

A20B-0303-C074 GE

IC3000CS200M GE DCS

IC693DSM302 GE PLC

IC693ALG390D

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922