Description

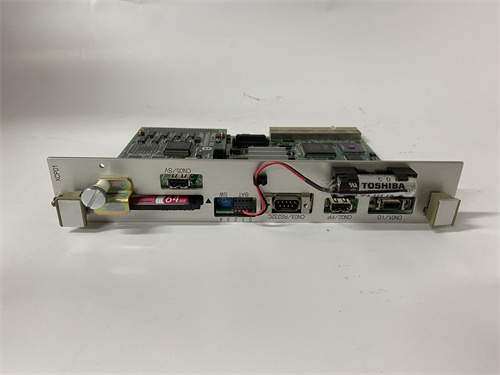

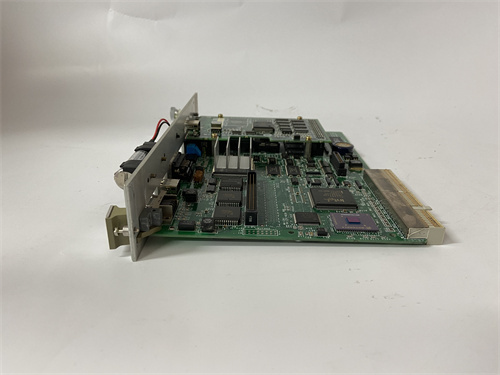

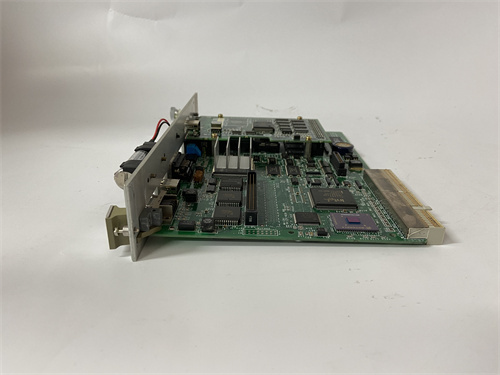

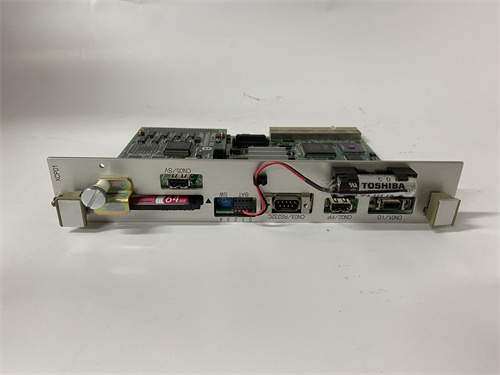

Product Description

Yaskawa JANCD-FC260 is a critical communication interface module for Yaskawa’s Motoman robot controllers (specifically DX200 and DX100 series), engineered to enable seamless data exchange between the robot controller and external automation systems (PLCs, HMIs, safety devices). As a core component of Yaskawa’s robotic integration ecosystem, Yaskawa JANCD-FC260 supports industrial fieldbus protocols including Profinet, Ethernet/IP, and DeviceNet, bridging the gap between robotic cells and factory-wide control networks. Unlike generic communication modules, Yaskawa JANCD-FC260 is factory-calibrated for Motoman robot systems, ensuring real-time transmission of robot position, status, and I/O signals with minimal latency [Product Link: Please supplement], where you can access the module’s protocol compatibility list and integration guide. In practical applications, Yaskawa JANCD-FC260 is deployed in automotive welding cells, electronics assembly lines, and palletizing systems, working alongside Yaskawa CP451-10-S2 HMIs to enable centralized monitoring and control of robotic operations. Additionally, Yaskawa JANCD-FC260 features a rugged design for industrial environments, redundant communication paths (for critical applications), and compliance with global safety standards, making it a reliable solution for integrating Yaskawa robots into complex automation workflows.

Product Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Module Type | Robot controller communication interface module (DX200/DX100 compatible) |

| Supported Protocols | Profinet IO, Ethernet/IP, DeviceNet, Modbus TCP/RTU |

| Communication Interfaces | 2× Ethernet ports (10/100 Mbps), 1× DeviceNet port, RS-232/RS-485 serial ports |

| Data Transmission Latency | ≤10ms (Profinet/Ethernet/IP) |

| I/O Signals | 16 digital inputs, 16 digital outputs (24 VDC) for direct safety device connection |

| Operating Temperature | 0°C ~ 55°C (operation), -20°C ~ 65°C (storage) |

| Protection Grade | IP20 (panel mounting) |

| Power Supply | 24 VDC ±10% (from robot controller) |

| Compatibility | Yaskawa DX200/DX100 robot controllers, Motoman GP/HP series robots, CP451-10-S2 HMIs |

| Certification | CE, UL 508, cULus, RoHS, ISO 13849-1 (Safety Category 3) |

| Dimensions (L×W×H) | 140 mm × 100 mm × 50 mm |

| Weight | 0.6 kg |

Advantages and Features

- Multi-Protocol Support: Yaskawa JANCD-FC260 integrates Profinet, Ethernet/IP, and DeviceNet, enabling seamless integration with major industrial control systems (Siemens, Allen-Bradley, Mitsubishi) without additional gateways.

- Real-Time Robot Data Transmission: ≤10ms latency ensures critical robot status and position data is transmitted instantly to PLCs/HMIs, enabling precise coordination between robots and peripheral equipment (e.g., conveyors, grippers).

- Safety Compliance: ISO 13849-1 Safety Category 3 certification and direct safety I/O connections make Yaskawa JANCD-FC260 suitable for safety-critical robotic applications (e.g., collaborative robot cells).

- Rugged Industrial Design: Wide operating temperature range and vibration resistance (EN 60068-2-6) ensure reliable performance in harsh manufacturing environments (e.g., automotive welding, metal fabrication).

- Seamless Yaskawa Ecosystem Integration: Optimized for DX200/DX100 controllers and Motoman robots, Yaskawa JANCD-FC260 eliminates compatibility issues and reduces integration time for robotic cell deployments.

- Redundant Communication Paths: Dual Ethernet ports support failover configurations, ensuring uninterrupted communication even if one network link fails—critical for 24/7 production environments.

Application Fields and Cases

Core Application Fields

- Automotive Industry: Motoman robot welding cell integration with Siemens PLCs, assembly line robotic arm coordination

- Electronics Industry: PCB assembly robot communication with Ethernet/IP-based control systems, component handling robot status monitoring

- Logistics Industry: Palletizing robot integration with warehouse management systems (WMS), conveyor-robot synchronization

- Food & Beverage Industry: Packaging robot data exchange with Profinet HMIs, pick-and-place robot safety interlock control

Typical Application Case

In a South Korean automotive manufacturer’s body-in-white welding line project, the plant deployed Yaskawa JANCD-FC260 modules in 12 Motoman HP20 robot cells to connect DX200 controllers to a Siemens S7-1500 PLC system via Profinet. Yaskawa JANCD-FC260 enabled real-time transmission of robot position and weld quality data to the PLC, ensuring precise coordination between robots and welding guns. The module’s redundant Ethernet ports prevented production downtime during a network switch failure, and its safety I/O connections triggered immediate robot stops if a safety door was opened. Yaskawa JANCD-FC260 reduced integration time by 25% compared to generic communication modules and improved welding line efficiency by 18% [Product Link: Please supplement] (see the project’s robot-PLC coordination report and uptime metrics).

Competitor Comparison (vs. Fanuc A03B-0823-C001 Communication Module)

| Comparison Dimension | Yaskawa JANCD-FC260 | Fanuc A03B-0823-C001 Communication Module |

|---|---|---|

| Supported Protocols | Profinet, Ethernet/IP, DeviceNet, Modbus | Ethernet/IP, Modbus (no Profinet/DeviceNet) |

| Latency | ≤10ms | ≤20ms |

| Safety Compliance | ISO 13849-1 Cat 3 | ISO 13849-1 Cat 2 |

| Compatibility | Yaskawa DX200/DX100 controllers | Fanuc R-30iB controllers |

| Redundant Ports | Dual Ethernet (failover) | Single Ethernet |

| Operating Temperature | 0°C ~ 55°C | 0°C ~ 50°C |

| Cost-Effectiveness | Mid-range (multi-protocol + redundancy) | Mid-range (single-protocol) |

Selection Suggestions

- Robot Controller Compatibility: Prioritize Yaskawa JANCD-FC260 for Yaskawa DX200/DX100 controllers; choose Fanuc modules for Fanuc robot systems.

- Protocol Requirements: Select Yaskawa JANCD-FC260 if Profinet or DeviceNet is needed; Ethernet/IP-only applications may use simpler modules.

- Safety Needs: Use Yaskawa JANCD-FC260 for Safety Category 3 applications (e.g., high-speed robotic cells); Cat 2 applications may use lower-cost alternatives.

- Redundancy Requirements: Choose Yaskawa JANCD-FC260 for 24/7 production environments requiring failover communication; single-port modules suffice for non-critical applications.

- Spare Parts Planning: Reserve one Yaskawa JANCD-FC260 module per 5 robot cells to ensure quick replacement in case of module failure.

Precautions

- Configure protocol settings (e.g., Profinet IO device name, Ethernet/IP scanner mode) using Yaskawa’s RobotStudio software to match the external control system’s requirements.

- Use shielded Ethernet cables for Profinet/Ethernet/IP connections and ground the shield layer at one end to minimize electromagnetic interference from welding equipment or motors.

- Test safety I/O connections after installation by simulating a safety trigger (e.g., emergency stop) to verify that the robot controller receives the signal and stops operation.

- Update the module’s firmware via the robot controller’s maintenance interface (not direct PC connection) to avoid compatibility issues with the DX200/DX100 system.

- Mount Yaskawa JANCD-FC260 in a well-ventilated area within the robot controller cabinet to maintain operating temperature within 0°C ~ 55°C.

- Store spare modules in anti-static packaging in a dry, temperature-controlled environment (-20°C ~ 65°C) to prevent moisture or static damage to internal components.

IC697BEM711 DCS

531X309SPCAJG1 DCS

IC695NIU001-CJ GE DCS

IC697BEM713 GE DCS

IC697MEM715B GE

IC697MEM717B GE

IC670PBI001-BE GE DCS

IC670CHS002Z GE

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922 Wechat:+86 15343416922

Wechat:+86 15343416922