Description

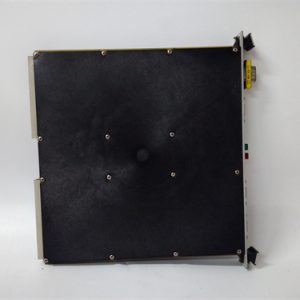

Product Description WOODWARD 9907-1365

WOODWARD 9907-1365 is an advanced controller for managing and protecting natural gas and propane engines by Woodward, designed for medium-sized industrial installations and generator systems. This model WOODWARD 9907-1365 combines high precision in regulation with extended protection functions, making it ideal for facilities with strict reliability requirements (such as gas power stations for shopping malls, industrial heating systems) featuring engines ranging from 30 kW to 300 kW. WOODWARD 9907-1365 ensures stable operation under variable loads and changes in gas quality, minimizing fuel consumption and emissions. WOODWARD 9907-1365 easily integrates with local PLCs and monitoring systems via industrial protocols, simplifying operator control. WOODWARD 9907-1365 is certified to EN 50545 and AGA 3 standards, confirming compliance with international requirements for gas equipment. [Insert product link here, enwrapping it in brand and model: WOODWARD 9907-1365]

Product Parameters WOODWARD 9907-1365

- Device Type: Controller for medium-power gas engines with adaptive regulation and comprehensive protection functions.

- Functional Parameters:

- Speed regulation range: 1000–3000 rpm (configurable) — suitable for generators and industrial-purpose engines.

- Regulation accuracy: ±0.3% of nominal speed — stability for systems with sensitive equipment (e.g., computers in shopping centers).

- Operating modes: Automatic adaptation to gas quality, grid synchronization, manual control, gas pressure monitoring — flexibility for various scenarios.

- Protection types: Overspeed (2 levels), low gas pressure, overheating (exhaust gas temperature), ignition system failure — protection against accidents and environmental standard violations.

- Supported sensors: Gas pressure sensors (4–20 mA), K-type thermocouples, magnetic speed sensors (12–60 teeth), ignition sensors — comprehensive monitoring of engine status.

- Supported protocols: Modbus RTU, Ethernet/IP — integration with PLCs and operator panels (e.g., Allen-Bradley PanelView).

- Electrical Parameters:

- Power supply: 24 VDC (redundant) — protection against power loss in critical systems.

- Current consumption: ≤150 mA — moderate energy usage.

- Control outputs: 3 analog outputs 4–20 mA (gas supply regulation, throttle), 5 relay outputs (NC/NO, 5 A, 250 VAC) — control of valves, signal lamps.

- Mechanical Characteristics:

- Housing material: Aluminum with anti-corrosive coating — resistance to aggressive gas components.

- Protection class: IP20 — installation in gas equipment control cabinets.

- Temperature range: -20°C – 65°C (operating); -40°C – 80°C (storage) — operation in moderate and cold climates.

- Dimensions: 100 × 150 × 45 mm (width × depth × height) — compact design for installation in limited spaces.

Advantages and Features WOODWARD 9907-1365

- Adaptation to gas quality: WOODWARD 9907-1365 automatically adjusts gas supply when its composition changes (e.g., fluctuations in propane content in mixtures), maintaining engine stability and reducing fuel consumption by 4–6% compared to static controllers.

- Two-level overspeed protection: Independent verification of signals from different sensors ensures WOODWARD 9907-1365 shuts down the engine during critical overspeed, preventing equipment damage.

- Flexible integration: Support for popular protocols allows WOODWARD 9907-1365 to be implemented in existing systems without replacing core equipment, reducing setup time.

- Resistance to aggressive environments: The anti-corrosive housing protects the controller from toxic gas components (e.g., hydrogen sulfide), extending service life by 1.5 times compared to standard models.

Application Cases in Fields

- Gas power stations for commercial facilities:

- Controlling generators in shopping centers and office complexes: WOODWARD 9907-1365 ensures stable power supply, synchronizes with the grid, and protects against overloads during peak hours (e.g., opening times).

- Industrial heating systems:

- Regulating engines of gas pumps and compressors: The controller optimizes gas supply, reducing consumption under partial loads and preventing overheating in high-intensity heating zones.

- Automotive gas stations:

- Managing compressor engines for vehicle refueling: WOODWARD 9907-1365 stabilizes gas pressure in the system, ensuring safe and accurate refueling.

Comparison with Competing Products

Compared to similar controllers (Cummins Gas Engine Control, Kohler K-2000), WOODWARD 9907-1365 offers:

- Better adaptation to gas quality: Automatic adjustment within 3–5 seconds vs. 10–15 seconds in competitors — faster response to fuel composition changes.

- More protection features: Two-level overspeed protection and ignition status monitoring, absent in some alternatives — enhanced reliability.

- Wider temperature range: Operation down to -20°C vs. -10°C in competitors — suitability for northern regions.

Selection Suggestions and Precautions

- Selection: Recommended for gas engines with 30–300 kW capacity in commercial, industrial, and energy facilities. Fully compatible with Caterpillar G3300, Cummins CG Series, and Kubota GX engines.

- Precautions:

- For WOODWARD 9907-1365, regularly calibrate gas pressure sensors (every 6 months) — inaccurate data will lead to suboptimal regulation and increased consumption.

- Use only certified gas filtration systems — contaminants can damage sensors and the controller.

- Update firmware via Woodward GasPro software — new versions include adaptive algorithm improvements for new gas types.

- Mount the controller at least 1 meter from electromagnetic interference sources (transformers, power cables) — ensuring stable sensor signals.

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922 Wechat:+86 15343416922

Wechat:+86 15343416922