Description

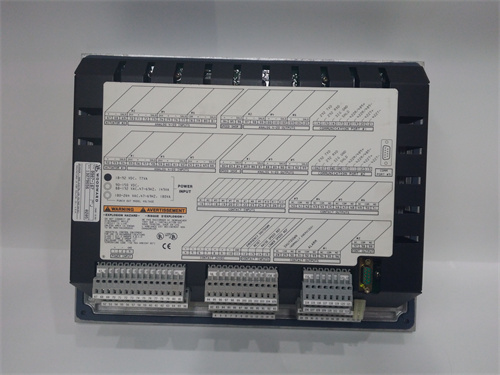

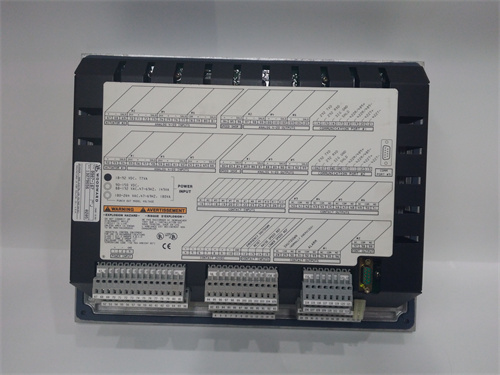

WOODWARD 9907-167 Governor Control Module

Product Description

The WOODWARD 9907-167 is a specialized digital speed control and protection module designed for industrial and mechanical drive turbine control applications. This module is part of Woodward’s renowned line of governor systems, which are critical for precisely regulating the speed of prime movers like gas turbines, steam turbines, and reciprocating engines. The WOODWARD 9907-167 serves as the central processing unit of a governor system, executing control algorithms to maintain set speed or load by adjusting fuel valves, steam admission valves, or other actuators. It interfaces with speed sensors (magnetic pickups), actuator drives, and a higher-level control system (like a plant DCS) to ensure stable and efficient operation of the driven equipment. Engineered for extreme reliability in critical power generation and compression applications, this module is a vital component for safe and efficient plant operation. For comprehensive technical documentation, application notes, and configuration tools, please visit the official product resource: WOODWARD 9907-167. The integration of the 9907-167 module into a turbine control panel provides the sophisticated logic needed for start-up sequencing, speed ramping, isochronous load sharing, and protection against overspeed conditions. The performance and reliability of the WOODWARD 9907-167 are foundational to the operational integrity of the entire turbomachinery train.

Product Parameters

- Product Model: WOODWARD 9907-167

- Series: Part of Woodward’s 9907 Governor product family.

- Module Type: Digital Governor Control Module / CPU.

- Control Functions: Speed control, acceleration control, load control (isochronous/droop), and start-up sequencing.

- Inputs:

- Speed Sensing: Typically accepts input from two magnetic pickups (MPUs) for redundancy and speed measurement.

- Analog Inputs: For setpoint signals (4-20mA, 0-10V), process variables (pressure, temperature), and actuator feedback.

- Digital Inputs: For contact closures (run commands, permissives, reset).

- Outputs:

- Actuator Drive: Provides output to drive a proportional actuator (e.g., -200mA to +200mA) or to control a servo valve.

- Analog Outputs: For meter drives or signals to a DCS.

- Digital Outputs/Relays: For status indication (running, alarm, trip) and control functions.

- Communications: Equipped with serial communication ports (e.g., RS-232/485) for configuration and for interfacing with plant control systems using protocols like Modbus RTU.

- Protections: Integral overspeed protection, sensor failure detection, and system diagnostics.

- Configuration: Programmed and tuned using Woodward’s proprietary software tool (e.g., Toolbox).

- Power Supply: Operates on a specified DC voltage (e.g., 24V DC).

Advantages and Features

- Precise and Stable Control: Offers highly accurate speed regulation with minimal droop, essential for maintaining grid frequency in gensets or process speed in compressors and pumps.

- High Reliability and Redundancy: Designed with features like dual MPU inputs and comprehensive self-diagnostics to ensure continuous, fault-tolerant operation in 24/7 critical applications.

- Flexible Configuration: Highly programmable control algorithms and adjustable parameters allow it to be tailored to a wide variety of turbine types, actuator types, and application requirements.

- Integrated Protection: Built-in overspeed detection and protection functions act as a primary safety layer, often capable of initiating an independent shutdown to protect the turbine from catastrophic failure.

- Proven Industry Application: Benefits from Woodward’s long-standing expertise in turbine control, with a vast installed base and deep application knowledge in power generation, oil & gas, and marine industries.

Application Cases in Various Fields

- Gas Turbine Generator Set (Power Plant): Regulates the speed of a gas turbine driving a generator, maintaining 50/60 Hz frequency in island mode or while synchronizing to the grid.

- Pipeline Compressor Drive: Controls the speed of a gas turbine or motor driving a centrifugal compressor, maintaining precise discharge pressure and avoiding surge conditions.

- Marine Propulsion: Used as the governor for the main propulsion turbine or diesel engine on a ship, controlling vessel speed through the propulsion system.

- Industrial Mechanical Drive: Controls a steam turbine driving a large process compressor or pump in a refinery or chemical plant, ensuring constant speed under varying load conditions.

Comparison with Competing Products

The WOODWARD 9907-167 competes with digital governor controllers from manufacturers like GE (Mark VIe Turbine Control), Siemens (SIPART DR), and ABB (UNITROL). Its primary advantages are Woodward’s specialization in governing technology, the module’s robust design for standalone or integrated control, and its strong reputation for mechanical drive applications. Compared to using a generic PLC for speed control, the 9907-167 is a purpose-built device with dedicated algorithms, high-speed dedicated I/O for speed sensing, and certified overspeed protection logic that a standard PLC cannot replicate. It represents a specialized, high-integrity control solution for critical rotating equipment.

Selection Suggestions and Precautions

- Application-Specific Engineering: The WOODWARD 9907-167 must be selected and configured for the specific prime mover (turbine/engine type), actuator type, and application (speed control, load control). Consultation with a Woodward application engineer is highly recommended.

- Speed Sensor (MPU) Compatibility and Installation: Correct selection, installation, and gap setting of the magnetic pickups (MPUs) are critical. Faulty speed sensing is a leading cause of governor malfunction or nuisance trips.

- Actuator Matching and Tuning: The actuator (hydraulic, electric, pneumatic) must be compatible with the controller’s output drive. Careful tuning of the control loops (gain, reset, ramp rates) using the Woodward Toolbox software is required for optimal performance.

- Overspeed Protection Validation: The overspeed protection function is a critical safety feature. Its setting and operation must be validated during commissioning and periodically tested according to safety and reliability standards.

MAC112D-0-FD-2-C/130-A-2/S013 PLC

Kontron CP369, 31.263-1010.1 B/00 PLC

4PP420.0571-45 PLC

DSQC679 PLC

AIP444-S1 PLC

DSQC663 PLC

BERGERLAHRWD3-007 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922