Description

Product Overview and Description

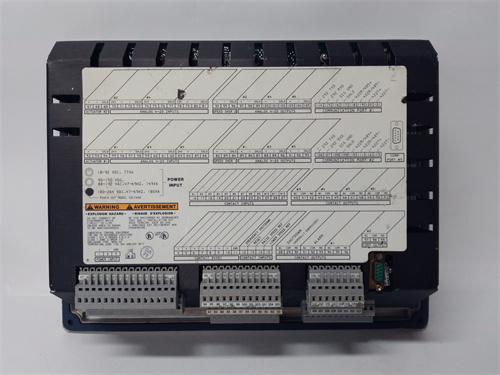

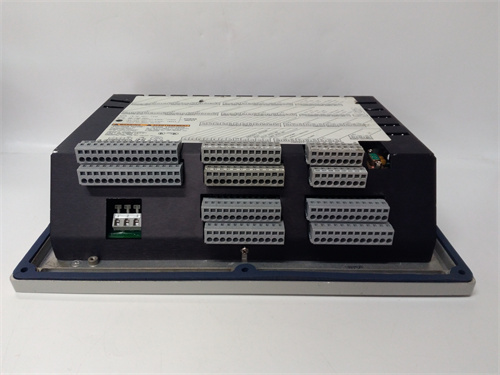

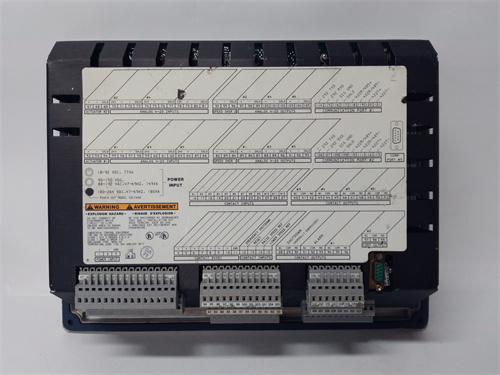

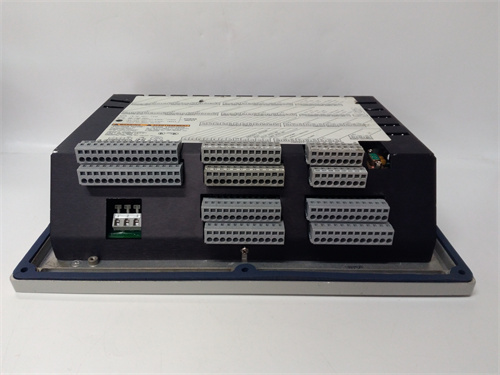

The WOODWARD 9907-162 is a critical Network Interface Module (NIM) designed for Woodward’s MicroNet family of digital turbine controls. This module serves as the primary communications gateway, facilitating reliable and deterministic data exchange between the MicroNet controller’s main processor and external systems like a plant Distributed Control System (DCS), Human-Machine Interface (HMI), or a higher-level supervisory network. The integration of the WOODWARD 9907-162 is essential for modernizing turbine control by enabling remote monitoring, setpoint adjustment, data logging, and integration into plant-wide automation strategies. As a sophisticated spare part, the WOODWARD 9907-162 ensures that critical turbine operational data—such as speed, temperature, valve position, and alarms—are communicated seamlessly and reliably. The robust performance of the WOODWARD 9907-162 makes it a vital component for maintaining operational visibility and control in demanding power generation and mechanical drive applications.

Key Parameters and Specifications

- Manufacturer & System: Woodward, for the MicroNet TMR (Triple Modular Redundant) Control System.

- Module Type: Network Interface Module (NIM).

- Primary Function: Provides high-speed, redundant communication between the MicroNet controller and external networks.

- Network Protocols: Typically supports industry-standard protocols such as:

- Modbus TCP/IP (Ethernet)

- Modbus RTU (Serial RS-232/485)

- OPC (for connectivity with Windows-based HMI/SCADA)

- Proprietary Woodward peer-to-peer protocols (for synchronization with other controllers).

- Physical Interfaces: Includes Ethernet ports (RJ-45) and serial communication ports (terminal blocks or DB connectors).

- Redundancy: Often designed to be hot-swappable and may support redundant network paths to ensure communication availability.

- Power Supply: Powered from the MicroNet control rack’s backplane.

- Status Indicators: Multiple LEDs for power, network activity, link status, and fault conditions.

Advantages and Distinctive Features

The WOODWARD 9907-162 offers significant advantages in connectivity and system integration. Its primary strength is providing a certified and reliable bridge between the safety-critical MicroNet control environment and the plant’s information network, without compromising the integrity of the turbine control logic. A key feature is its support for multiple, simultaneous communication protocols, allowing flexible integration with various plant systems from different eras. The module is engineered for high noise immunity and deterministic performance, ensuring that critical data packets (like trip signals or speed setpoints) are delivered without unacceptable latency. The hot-swap capability of the WOODWARD 9907-162 allows for maintenance or replacement without taking the turbine offline, maximizing availability. Its configuration is managed through Woodward’s toolset, ensuring a seamless and validated setup that aligns with the overall control strategy.

Application Cases in Key Fields

- Combined Cycle Power Plants: Serving as the communications link between a MicroNet-controlled gas turbine and the plant’s central DCS (e.g., Emerson DeltaV, Siemens PCS 7), allowing operators to start/stop the unit, adjust load, and monitor hundreds of parameters from the main control room.

- Compressor Station Control: Enabling the integration of a MicroNet-controlled turbine-driven compressor into a pipeline’s SCADA system, allowing for remote performance monitoring and coordination of multiple units along the pipeline.

- Marine Propulsion: Facilitating data exchange between the MicroNet controller for a ship’s main propulsion gas turbine and the vessel’s integrated automation system (IAS) for centralized monitoring and control from the bridge.

- Independent Power Producers: Providing the critical OPC or Modbus TCP link for a remote performance monitoring service to analyze turbine efficiency and predict maintenance needs.

Comparison with Competing Products

The WOODWARD 9907-162 is a proprietary interface specific to the Woodward MicroNet architecture. Competing network modules from other turbine control OEMs (e.g., GE’s Mark VIe HMI/COMM cards or Siemens’ T3000 communication processors) offer similar functionality but are part of closed, non-interchangeable ecosystems. Compared to generic industrial Ethernet gateways or protocol converters, the WOODWARD 9907-162 is deeply integrated into the MicroNet’s operating system, offers validated performance, supports deterministic data transfer for critical signals, and includes Woodward-specific diagnostics and configuration tools. It is distinct from basic I/O modules within the MicroNet rack, as its function is purely for external system connectivity and data concentration.

Selection Suggestions and Precautions

Selection Suggestions:

- Select the WOODWARD 9907-162 specifically for expanding communication capabilities or replacing a failed NIM in an existing Woodward MicroNet TMR control system.

- It is the mandatory choice when adding a new external communication link (e.g., connecting to a new plant DCS) that requires a protocol supported by this module.

- Always verify the specific firmware version and hardware revision for compatibility with the existing MicroNet controller chassis and the plant’s network requirements.

Important Precautions:

- Network Segmentation: For cybersecurity, the network connected to the WOODWARD 9907-162 must be properly segmented from the business IT network using firewalls and managed switches. Turbine controls are critical infrastructure and must be protected from unauthorized access.

- Configuration Backup & Restore: Before replacing a module, the complete communication configuration (IP addresses, node IDs, data mapping) must be backed up using Woodward’s toolset (e.g., Toolbox). This configuration must be restored to the new WOODWARD 9907-162.

- Static IP Assignment: Use static IP addresses, not DHCP, for the module’s Ethernet interface to ensure reliable and deterministic communication with the DCS/HMI.

- Grounding and Shielding: Adhere strictly to Woodward’s installation guidelines for communication cable shielding and grounding to prevent electromagnetic interference (EMI) from causing data corruption or communication faults.

- Post-Replacement Testing: After installation, thoroughly test all communication functions. Verify that the DCS can read critical parameters, write to permitted setpoints, and receive alarms. Test redundancy by simulating a failure on the primary network path.

SAFT181INF

SAFT189ISI PLC

SAFT160F380 ABB PLC

SAFT-168PAC ABB PLC

ABB SAFT192POW PLC

ABB DSAI133 PLC

USART86 ABB PLC

SAFP25PAN ABB PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922