Description

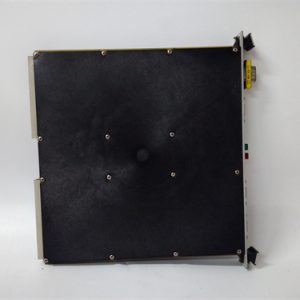

Woodward 8273-1020 is a high-performance digital speed controller developed by Woodward, a leading manufacturer of control systems for industrial and aerospace applications. Specifically engineered for precise speed regulation of prime movers such as diesel engines, gas turbines, and steam turbines, this controller plays a critical role in maintaining stable operation, optimizing energy efficiency, and ensuring safety in power generation, marine propulsion, oil and gas, and heavy-duty machinery sectors. With its advanced control algorithms, robust construction, and versatile compatibility, Woodward 8273-1020 has become a trusted component in mission-critical systems where speed accuracy and reliability are paramount.

Product Parameters

| Category | Details |

|---|---|

| Equipment Type | Digital Speed Controller for Prime Movers |

| Speed Control Range | 100 RPM to 10,000 RPM |

| Speed Regulation Accuracy | ±0.1% of set speed (steady state) |

| Input Signals | Magnetic pickup (MPU) input (0.1 Vrms to 20 Vrms), 4-20 mA process input, digital status inputs (4 channels) |

| Output Signals | 4-20 mA proportional output (2 channels), relay outputs (3 channels for alarms/shutdowns) |

| Power Supply | 12 VDC / 24 VDC ±10%, power consumption ≤15 W |

| Operating Temperature | -40°C to +70°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Protection Rating | IP54 (NEMA 4X for enclosure options) |

| Communication Interfaces | RS-485 (Modbus RTU), optional Ethernet (Modbus TCP/IP) |

| Certifications | CE, UL, CSA, ATEX (for hazardous areas), IEC 61508 (SIL 2) |

Advantages and Features

1. Precise Speed Regulation with Advanced Algorithms

Woodward 8273-1020 incorporates state-of-the-art proportional-integral-derivative (PID) control algorithms with adaptive tuning capabilities, enabling it to maintain exceptional speed stability even under varying load conditions. Whether adjusting to sudden changes in power demand in a generator set or compensating for fuel pressure fluctuations in a marine engine, the controller responds rapidly with minimal overshoot, ensuring the prime mover operates within tight speed tolerances. This precision not only enhances equipment performance but also extends the lifespan of mechanical components by reducing wear and tear.

2. Robust Design for Harsh Environments

Built to withstand the rigors of industrial and offshore environments, Woodward 8273-1020 features a rugged enclosure and components rated for extreme temperatures, vibration, and electromagnetic interference (EMI). It complies with EN 61000 EMI standards and is resistant to voltage surges and transient spikes, making it suitable for installation in oil rigs, mining equipment, and remote power plants. The optional IP54/NEMA 4X enclosure provides additional protection against dust, water, and corrosive substances, further expanding its applicability in harsh operating conditions.

3. Versatile Compatibility and Expandability

The controller offers broad compatibility with various prime movers and auxiliary equipment, supporting magnetic pickup inputs for speed sensing and integrating seamlessly with fuel injection systems, governors, and safety shutdown devices. Woodward 8273-1020 also supports industry-standard communication protocols, allowing for easy integration into centralized control systems (CCS) and SCADA networks. With optional Ethernet connectivity, it enables remote monitoring and parameter adjustment, while expandable I/O modules cater to custom application requirements, eliminating the need for additional control hardware.

4. Comprehensive Safety and Diagnostic Functions

Safety is a core design priority of Woodward 8273-1020, which includes built-in over-speed protection, under-speed alarms, and fault detection mechanisms. In the event of a speed deviation beyond safe limits, the controller triggers immediate shutdown or alarm outputs to prevent equipment damage or safety hazards. It also features advanced diagnostic capabilities, continuously monitoring internal components, input/output signals, and communication links. Fault logs are stored locally and can be accessed remotely, facilitating quick troubleshooting and minimizing downtime for maintenance.

Application Fields and Cases

1. Power Generation: Diesel Generator Sets for Emergency Backup

A data center in a disaster-prone region deployed Woodward 8273-1020 to control its fleet of diesel generator sets. The controller ensures the generators maintain a stable speed of 1500 RPM (50 Hz) during power outages, delivering consistent electrical output to critical IT infrastructure. Its adaptive PID tuning compensates for load changes as servers and cooling systems start up, preventing voltage fluctuations that could damage sensitive equipment. The integrated over-speed protection has also prevented potential generator failures, ensuring 99.99% uptime for the data center’s backup power system.

2. Marine Propulsion: Main Engines for Commercial Vessels

A shipping company retrofitted its fleet of container ships with Woodward 8273-1020 to control the speed of their marine diesel engines. The controller integrates with the ship’s navigation system, automatically adjusting engine speed to optimize fuel efficiency based on voyage conditions (e.g., sea state, cargo load). During a transatlantic voyage, the controller reduced fuel consumption by 8% compared to the previous control system, resulting in significant operational cost savings. Its robust design also withstood the harsh marine environment, including salt spray and high vibration, with zero unplanned downtime over a 12-month period.

3. Oil and Gas: Gas Turbines for Pipeline Compression

An oil and gas company utilized Woodward 8273-1020 to regulate the speed of gas turbines powering pipeline compression stations. The controller maintains precise turbine speed to ensure consistent gas flow rates while adapting to changes in natural gas pressure and temperature. Its advanced diagnostics detected a faulty fuel injector early, allowing maintenance teams to replace the component during a scheduled outage instead of facing an unplanned shutdown. This proactive maintenance approach reduced downtime by 40% and prevented potential disruptions to the pipeline network.

Comparison with Competitors

| Comparison Dimension | Woodward 8273-1020 | Competitor (A Leading Brand Speed Controller) |

|---|---|---|

| Speed Regulation Accuracy | ±0.1% (steady state) | ±0.2% (steady state) |

| Operating Temperature Range | -40°C to +70°C | -20°C to +60°C |

| Communication Options | RS-485 + optional Ethernet | RS-485 only |

| Safety Certifications | IEC 61508 (SIL 2), ATEX | IEC 61508 (SIL 1), no ATEX |

| Expandability | Optional I/O modules | Fixed I/O, no expandability |

| Adaptive Tuning | Yes, automatic PID tuning | Manual PID tuning only |

Selection Recommendations and Precautions

Selection Recommendations

- Prime Mover Compatibility: Choose Woodward 8273-1020 for diesel engines, gas turbines, or steam turbines requiring high-precision speed control, especially in applications with variable load conditions.

- Harsh Environment Requirements: Opt for this controller for installations in extreme temperatures, high vibration, or corrosive environments, such as offshore platforms, mining sites, and industrial plants.

- Integrated Control Systems: Select it for projects requiring integration into SCADA or CCS networks, as its communication capabilities support remote monitoring and centralized control.

- Safety-Critical Applications: Prioritize Woodward 8273-1020 for systems requiring SIL 2 safety certification, such as power generation and oil and gas compression stations.

Precautions

- Installation: Mount the controller in a well-ventilated location away from heat sources and direct sunlight. Ensure proper grounding to minimize EMI interference, and use shielded cables for input/output connections.

- Calibration: Perform initial speed calibration using a calibrated tachometer to ensure accurate speed sensing. Regularly verify and adjust PID parameters based on changes in operating conditions or equipment performance.

- Wiring: Follow the manufacturer’s wiring diagrams to avoid incorrect connections, which could damage the controller or prime mover. Use appropriate wire gauges for power and signal lines to prevent voltage drops.

- Maintenance: Conduct periodic inspections of the controller’s enclosure, connectors, and cooling vents. Clean dust and debris regularly, and update firmware to the latest version as recommended by Woodward to access new features and bug fixes.

- 8273-1020

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922