Description

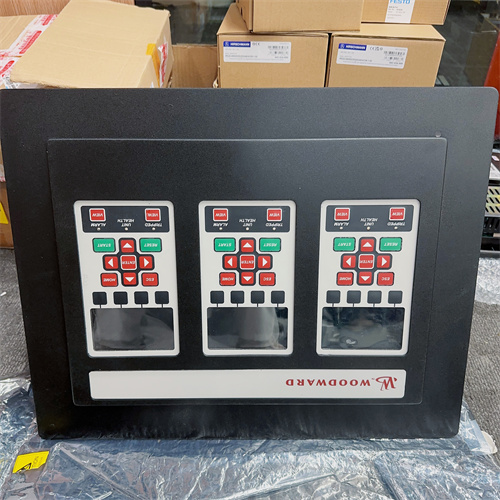

Product Description

The WOODWARD 8200-1302 is a critical actuator position feedback module or interface card designed for integration within Woodward’s 8200 series digital governor and control systems for engines and turbines. This module is responsible for providing precise and reliable feedback regarding the position of a fuel metering valve, actuator, or other final control element to the main governor controller. The WOODWARD 8200-1302 typically interfaces with an LVDT (Linear Variable Differential Transformer) or RVDT (Rotary Variable Differential Transformer) sensor, conditioning the raw sensor signal into a high-integrity digital or analog value used for closed-loop position control. For detailed technical specifications, calibration procedures, and wiring diagrams, the primary resource is the official Woodward support and documentation portal for the WOODWARD 8200-1302. The accurate position feedback provided by the 8200-1302 is essential for the governor to maintain precise speed, load, or pressure control, making it a vital component for the stable and efficient operation of prime movers.

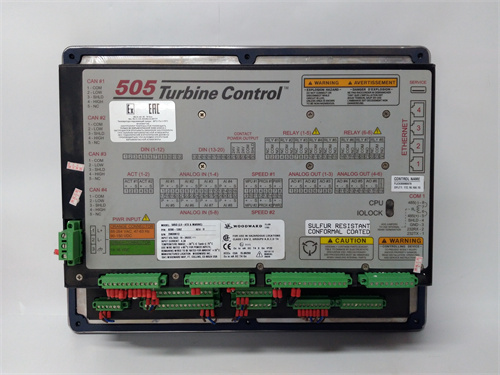

Product Parameters

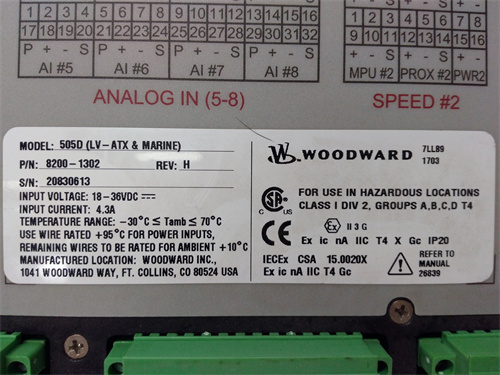

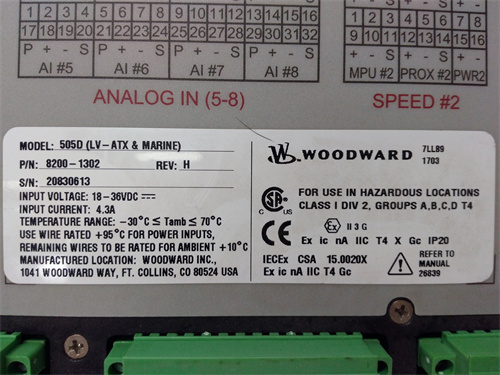

- Manufacturer / Brand: Woodward.

- Series: 8200 Digital Governor System.

- Model: 8200-1302 (Actuator Feedback Module / Position Feedback Card).

- Function: LVDT/RVDT Signal Conditioner and Position Feedback Interface.

- Input Signal: Accepts the AC output signal from an LVDT or RVDT sensor attached to an actuator.

- Output Signal: Provides a conditioned output, typically a scaled DC voltage (e.g., 0-10 VDC) or a digital representation of the measured position to the main controller.

- Excitation Output: Supplies the AC excitation voltage and frequency required to power the connected LVDT/RVDT sensor.

- Accuracy and Linearity: High accuracy and linearity specifications to ensure the position feedback precisely represents the actual mechanical movement.

- Adjustments: May include potentiometers or software-configurable parameters for zero (offset) and span (gain) calibration to match the specific actuator’s travel.

- Diagnostics: May include status indicators or fault detection for sensor wiring issues (open circuit, short circuit).

- Form Factor: A printed circuit board (PCB) assembly designed for installation within an 8200- series control cabinet or as a modular card.

- Compatibility: Designed to work with specific Woodward actuators and the 8200- series control platform.

Advantages and Features

- High Precision Feedback: Enables precise closed-loop control of actuator position, which is directly critical for accurate fuel metering, speed regulation, and load control.

- Robust Signal Conditioning: Effectively filters and conditions the low-level AC signal from the LVDT, providing a stable and noise-resistant DC output suitable for the digital controller.

- Integrated Sensor Excitation: Simplifies system design by providing the necessary power for the position sensor, eliminating the need for a separate excitation source.

- Reliable Operation: Engineered for the high-vibration and wide-temperature environments associated with engines and turbines.

- Essential for System Calibration: The zero and span adjustments on the WOODWARD 8200-1302 are key to calibrating the entire actuator control loop during commissioning and maintenance.

Application Cases in Industry

- Gas Turbine Fuel Control: The WOODWARD 8200-1302 provides critical position feedback from the gas control valve (GCV) or fuel stroke reference (FSR) actuator to the 8200 governor, ensuring precise fuel delivery for stable turbine operation.

- Diesel/Gas Engine Governing: Used on large industrial or marine engines to provide feedback from the fuel rack or actuator, allowing the governor to maintain set speed under varying load conditions.

- Steam Turbine Control: Provides position feedback from steam inlet valves or governor valves to the control system for accurate power output regulation.

- Compressor Control (Mechanical Drive): Used in pipeline compressor stations where a turbine-driven compressor is controlled, with the module feeding back actuator position for anti-surge or performance control.

- Hydrogen Turbine Applications: Provides reliable feedback in newer energy systems where precise control of fuel valves is critical.

Comparison with Competing Products

Competing products are position feedback modules from other turbine/engine control specialists like GE (Speedtronic Mark VIe I/O cards) or Emerson (formerly Bristol/Babcock). The WOODWARD 8200-1302 is a proprietary component deeply integrated into the Woodward 8200 ecosystem. Compared to a generic LVDT signal conditioner, the 8200-1302 is specifically calibrated, ruggedized, and electrically matched for Woodward’s control environment. Its primary advantage is guaranteed compatibility, performance, and support within a Woodward system, whereas a third-party conditioner would require extensive interface engineering and lack formal support for the safety-critical control function.

Selection Suggestions and Precautions

- Selection Suggestions:

- Select the WOODWARD 8200-1302 specifically as a replacement part for a failed module in an existing 8200 control system or as specified in a new system design from Woodward.

- Verify the compatibility of the module with the specific actuator model and the LVDT/RVDT sensor part number installed in the field.

- Confirm the module’s output signal type (e.g., 0-10V, 4-20mA) matches the input expectations of the main controller it connects to.

- Precautions:

- Calibration is Critical: After installation, the 8200-1302 module must be calibrated. This involves a two-point calibration (usually zero and full stroke) with the actuator in its verified mechanical limits. Incorrect calibration will cause erroneous control actions.

- Sensor Wiring: Use the correct, shielded cable specified by Woodward for the LVDT/RVDT connection. Maintain proper separation from power cables to prevent signal interference. Ensure connections are secure.

- Excitation Matching: Ensure the connected LVDT/RVDT sensor’s electrical specifications (excitation voltage, frequency) are compatible with the output of the 8200-1302 module.

- Handling: Treat the module as an ESD-sensitive device during handling and installation.

- Genuine Parts and Documentation: Source the WOODWARD 8200-1302 from authorized Woodward distributors or service centers. Obtain the specific calibration and installation procedure for your actuator/controller combination. Using non-genuine parts or incorrect calibration procedures risks unstable control, poor performance, or equipment damage.

2711-B6C20

9907-014

1747-L552

1FK7060-5AF71-1DU5-Z

CM5-4A-R-A-E-AVBE F-A-A-N PLC

PLX32-EIP-MBTCP PLC

FMH2A03TR-EN43CZ PLC

3HAC14551-2/06A PLC

8200-1302

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922