Description

Product Overview and Description

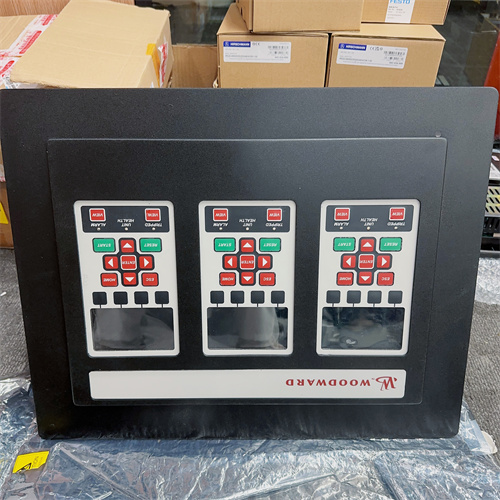

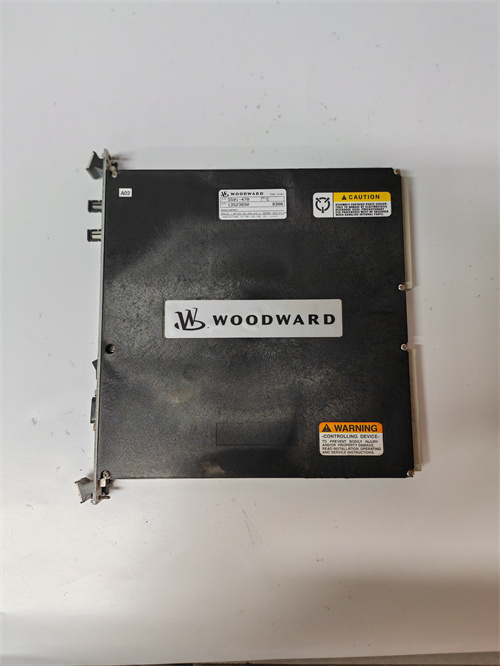

The WOODWARD 5501-470 is a specialized actuator interface module from Woodward’s extensive range of turbine and engine control components. This module functions as a critical intermediary, translating control signals from a governor or digital controller into precise electrical commands to manage a hydraulic actuator or electro-hydraulic servo valve (EHSV). The WOODWARD 5501-470 is engineered for reliability in demanding applications where precise positioning of fuel valves, inlet guide vanes, or other final control elements is required for speed, load, or pressure regulation. It is a key component in systems controlling gas turbines, steam turbines, and large diesel or gas engines.

Product Parameters

- Module Type: Actuator Driver / Servo Interface Module.

- Primary Function: Converts a low-power control signal (e.g., 4-20 mA, ±10 V DC) into a high-current drive signal for a proportional servo valve or actuator.

- Input Signals: Typically accepts analog command signals (4-20 mA, 0-10 V DC, ±10 V DC) and often includes position feedback signals (LVDT, RVDT) for closed-loop control.

- Output Drive: Provides a high-current, proportional output (e.g., ±80 mA or higher) to directly drive the coil of a proportional servo valve.

- Feedback Integration: Includes conditioning circuits for actuator position feedback devices (LVDT/RVDT), providing excitation and demodulating the return signal.

- Power Supply: Requires dedicated, well-regulated DC power supplies (e.g., ±15 V DC for logic, +24 V DC or higher for output stage).

- Diagnostics: May include monitoring for coil continuity, feedback signal loss, and output current limits.

- Metering & Adjustment: Often features potentiometers or digital interfaces for calibrating gain, bias, and current limits.

- Mounting & Environment: Designed for panel or DIN-rail mounting in industrial control enclosures.

Advantages and Key Features

- Precision Control: The WOODWARD 5501-470 is designed for accurate, proportional control of hydraulic actuators, enabling fine-tuning of turbine/engine parameters for optimal efficiency and stability.

- Robust Output Stage: Its high-current output drive is capable of directly powering industrial servo valve coils, eliminating the need for an additional amplifier stage and simplifying system architecture.

- Integrated Feedback Loop: Built-in excitation and demodulation for LVDT/RVDT sensors allows for direct, closed-loop position control of the actuator, improving accuracy and response.

- High Reliability: Built to industrial and often military-grade standards, the WOODWARD 5501-470 is known for its durability and stable performance in environments with significant vibration and temperature variation.

- System Compatibility: As a Woodward component, it is designed to integrate seamlessly with other Woodward governors, controllers, and protection modules, ensuring validated performance in critical control loops.

Application Cases in Various Fields

- Power Generation (Gas Turbines): Precisely positioning fuel control valves on a gas turbine to maintain grid frequency and manage load changes, driven by a Woodward governor through the WOODWARD 5501-470.

- Marine Propulsion: Controlling the pitch of a controllable pitch propeller (CPP) or the fuel rack on a large marine diesel engine for speed and maneuverability.

- Pipeline Compression: Modulating inlet guide vanes or recycle valves on a compressor driven by a gas turbine to maintain discharge pressure and avoid surge conditions.

- Industrial Turbines: Managing the steam inlet valves on an industrial steam turbine used for mechanical drive or co-generation in a paper mill or refinery.

Comparison with Competing Products

The WOODWARD 5501-470 competes with servo drive modules from other turbomachinery control specialists like GE (Mark VI I/O packs), Honeywell (actuator interfaces), and custom solutions from system integrators. Compared to a generic industrial servo amplifier, it is specifically tailored for the signals (e.g., LVDT feedback) and requirements (high reliability, specific form factor) of turbine control systems. Its primary advantage is its proven interoperability and support within the Woodward ecosystem, often being the specified component in original equipment designs. Competing modules from other OEMs offer similar functionality, making the choice often dictated by the existing control system brand and the need for guaranteed compatibility.

Selection Suggestions and Precautions

- Selection Advice:

- Signal Matching: Confirm the module’s input signal range (e.g., 4-20mA) matches the command signal from your controller. Verify its output current capability matches the coil requirements of your specific servo valve.

- Feedback Type: Ensure the WOODWARD 5501-470 is configured for the correct feedback device (LVDT model, excitation voltage, frequency) used in your actuator.

- System Design: This module is typically part of a larger control scheme. Ensure you have the complete wiring and interface diagrams from the original turbine/engine control system design.

- Important Precautions:

- Critical System Component: This device controls critical machinery. Installation, calibration, and maintenance should be performed by personnel trained on the specific turbine/engine control system.

- Power Supply Quality: Use highly regulated and filtered power supplies. Noise or voltage spikes on the supply lines can cause erratic actuator behavior and damage the module.

- Calibration Procedure: Proper calibration using the correct test equipment (mA source, LVDT simulator) is mandatory. Incorrect bias or gain settings can lead to poor control, instability, or unsafe actuator movement.

- Environmental Protection: Install in a properly rated enclosure to protect against dust, moisture, and excessive temperature, even though the module itself is robust.

- Obsolescence Management: For legacy systems, source the WOODWARD 5501-470 from authorized Woodward channels or certified refurbishers to ensure you receive a genuine, fully tested component. Documented calibration data from the supplier is highly valuable.

AL81G PLC

6445-001-K-N

CE15KN3 PLC

3BSE003911R0001

PFRA101 PLC

9100-00001-06 PLC DCS

MMS6823R DCS

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922