Description

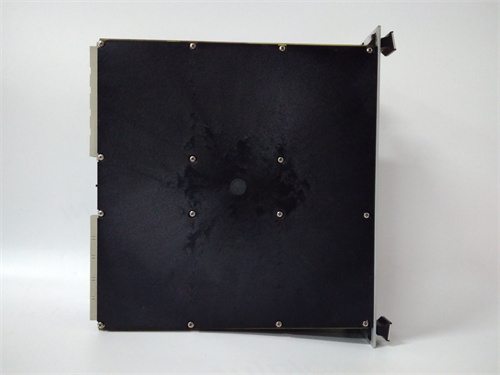

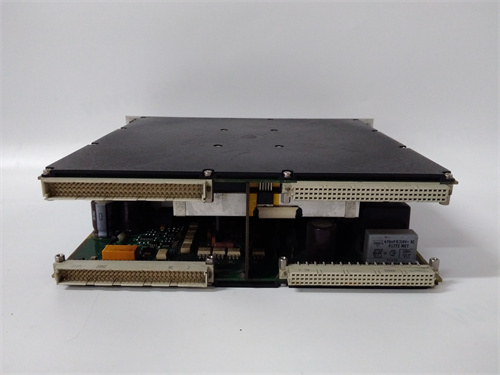

Product Overview and Description

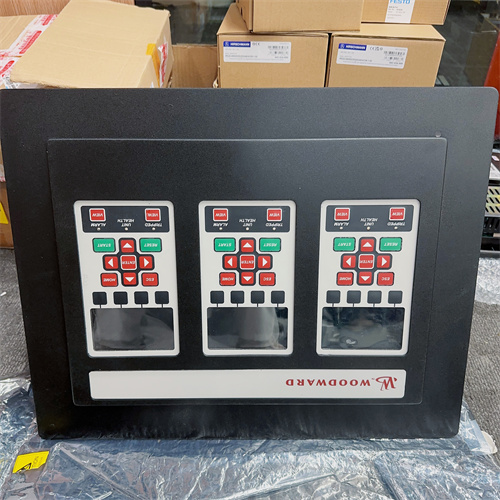

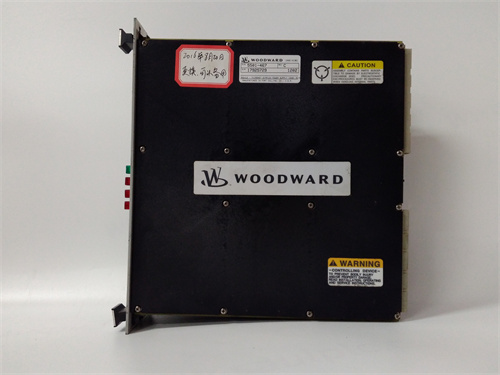

The WOODWARD 5501-467 is a critical Governor Control Output Driver module, specifically designed for Woodward’s 505/505E Digital Governor systems used to control steam and small gas turbines. This module is a specialized spare part that acts as the final, high-power interface between the governor’s control logic and the hydraulic actuator (servo valve) that physically positions the turbine’s steam inlet valves or fuel valves. The WOODWARD 5501-467 converts the low-level, precision control signal from the governor’s CPU into a high-current drive signal capable of rapidly and accurately moving the servo valve’s torque motor. The reliability and performance of the WOODWARD 5501-467 are directly linked to the turbine’s ability to maintain precise speed and load control, making it an indispensable component for both maintenance and ensuring operational stability. When integrated into the governor system, the WOODWARD 5501-467 plays a fundamental role in the fast, closed-loop control that defines modern turbine management.

Key Parameters and Specifications

- Manufacturer & System: Woodward, for the 505/505E Digital Governor.

- Module Type: Governor Control Output Driver (Servo Driver).

- Primary Function: Drives a servo valve torque motor (typically a +/- 200 mA proportional current loop).

- Output Signal: Proportional DC current output (e.g., +/- 200 mA or 4-20 mA) to command the servo valve position.

- Input Signal: Accepts a command signal (e.g., 0-5 VDC or digital command) from the governor’s main control board.

- Power Supply: Requires dedicated DC power inputs (e.g., ±12 VDC, +24 VDC) for the driver electronics and the output stage.

- Diagnostics: Typically includes monitoring for output current feedback, open circuit, and short circuit conditions. Status is often communicated back to the main CPU.

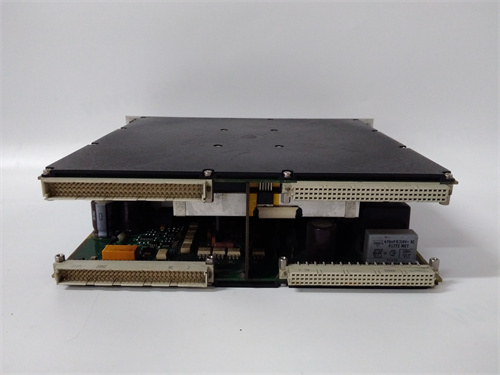

- Communication: Interfaces with the governor’s main processor, often via a dedicated connector on the 505 system’s backplane or harness.

- Mounting: Plugs into a designated slot on the 505 governor chassis or is mounted as a discrete module within the control cabinet.

Advantages and Distinctive Features

The WOODWARD 5501-467 provides precise, robust, and reliable actuation control. Its primary advantage is delivering a stable, high-fidelity current signal to the servo valve, which is essential for smooth turbine acceleration, load acceptance, and steady-state speed regulation. A key feature is its built-in diagnostics and current feedback loop, which allows the governor’s CPU to verify that the commanded output is being delivered correctly, enabling fault detection and safeguarding against runaway conditions. The module is designed for the high-vibration and electrically noisy environment typical of turbine skids. The optimized performance of the WOODWARD 5501-467 ensures minimal deadband and fast response, which are critical for stable turbine control during grid disturbances or rapid load changes. Its design is specifically matched to the Woodward 505’s control algorithms, ensuring system-level performance and reliability.

Application Cases in Key Fields

- Industrial Steam Turbines: Driving the hydraulic actuator for the governor valve on a mechanical-drive steam turbine powering a compressor or pump in a refinery or chemical plant. The WOODWARD 5501-467 ensures precise speed control under varying process loads.

- Generator Control (Small Gas Turbines): Acting as the servo driver for the fuel metering valve on a gas turbine generator set, controlling fuel flow to maintain constant speed (Hz) as electrical load changes.

- Cogeneration Plants: Managing the speed/load control of a back-pressure or extraction steam turbine in a combined heat and power (CHP) facility, balancing electrical output with steam demand.

- Sugar/Paper Mill Turbines: Providing precise control for turbines that use process steam, where the WOODWARD 5501-467‘s stable output is key to maintaining both turbine speed and downstream process pressure.

Comparison with Competing Products

The WOODWARD 5501-467 is a proprietary component within the Woodward 505 ecosystem. Competing servo driver modules from other turbine control OEMs (e.g., GE’s Speedtronic BDA modules or Siemens’ T3000 components) are not interchangeable, as they are designed for different controller architectures, signal levels, and communication protocols. Generic industrial servo amplifiers or analog output cards lack the specific calibration, diagnostics, and integration with the governor’s protective sequencing and tuning parameters that are inherent to the WOODWARD 5501-467. Within Woodward’s own range, it is a distinct part from the main CPU or I/O modules, serving the specialized function of high-current servo drive.

Selection Suggestions and Precautions

Selection Suggestions:

- Select the WOODWARD 5501-467 specifically as a replacement for a failed output driver in an existing Woodward 505 or 505E Digital Governor system, as identified by the system manual or fault diagnostics.

- It should be considered a critical spare part for any facility operating turbines with 505 governors to minimize downtime.

- Verify the exact model number and revision against the unit being replaced, as there may be different versions for specific 505 hardware revisions.

Important Precautions:

- Exact Replacement: Ensure the replacement WOODWARD 5501-467 is the correct revision for your specific 505 chassis. Mismatched revisions may not communicate or function correctly with the main CPU.

- System Configuration: The governor’s software may have specific configuration parameters (gain, limits) for the servo driver. After replacement, these parameters should be verified in the 505’s software (via the keypad or PC tool) against a known good backup.

- High-Power Hazard: Servicing must be performed with the turbine offline, the hydraulic actuator system isolated and depressurized, and all control power locked out/tagged out (LOTO). The output terminals are connected to inductive loads and can have high transient voltages.

- Calibration Required: After installation, a servo drive calibration procedure is mandatory. This typically involves using the 505’s service mode to adjust the driver’s null (zero) and span (gain) so that a 0% command results in zero servo current and a 100% command results in the correct full-scale current (e.g., +200 mA). Incorrect calibration can lead to poor control or actuator damage.

- Root Cause Analysis: A failure of the WOODWARD 5501-467 is often symptomatic of another issue, such as a failing servo valve coil, water intrusion, or power supply problem. Always inspect the field wiring, connectors, and the servo valve itself before installing the new module to prevent immediate re-failure.

ABB IOD86MEM PLC

ABB DSTD306 PLC

CPU86-10MHZ+S100M ABB PLC

GTO1300V880A ABB PLC

SAFT25F 380 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922