Description

Product Description

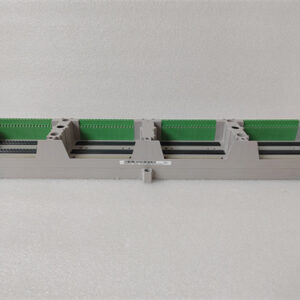

The WESTINGHOUSE 5X00058G01 is a nuclear-qualified instrumentation and control (I&C) module, part of Westinghouse’s specialized components for nuclear power plant safety and control systems. This module is typically a signal conditioning card, logic processor, or communication interface designed for installation within a qualified chassis of a reactor protection system, engineered safety features system, or other critical monitoring system. Manufactured under rigorous nuclear quality assurance standards (ASME NQA-1), the 5X00058G01 is engineered for exceptional reliability, long-term stability, and resilience against environmental stressors such as seismic events, temperature extremes, and electromagnetic interference. Its function is to accurately process sensor signals, execute predefined safety logic, or manage secure data communication, playing a direct role in maintaining the safe and controlled operation of nuclear reactor systems. The integrity of the WESTINGHOUSE 5X00058G01 is foundational to the overall safety architecture of the plant.

Product Parameters

- Module Type: Nuclear Qualified I&C Module (Specific function defined by plant documentation – e.g., Analog Input, Bistable Processor, Relay Driver).

- Application Domain: Westinghouse Nuclear Power Plant Safety & Control Systems (e.g., Reactor Protection System – RPS, ESFAS).

- Safety Classification: Class 1E (Essential for Safety) or equivalent Safety-Related classification.

- Qualification Standards: Qualified to IEEE 323 (Environmental Qualification) and IEEE 344 (Seismic Qualification) for nuclear service.

- Input/Output Specifications: Highly specific to its function. May include analog voltage/current inputs, digital status inputs, relay contact outputs, or communication data lines.

- Processing Logic: May implement fixed, hardwired logic or configurable logic for trip functions and sequences.

- Power Supply: Operates from a qualified Class 1E DC power source (e.g., 24V DC, 48V DC, 125V DC).

- Diagnostic Indicators: Includes status LEDs for power, health, and fault conditions.

- Physical Form: Printed Circuit Board Assembly (PCBA) designed for a specific qualified card file or rack.

- Environmental Rating: Designed for harsh nuclear environments, including radiation fields.

Advantages and Features

- Ultimate Reliability and Safety-Critical Design: The WESTINGHOUSE 5X00058G01 is designed with failure prevention as a priority, incorporating principles like redundancy, diversity, and fail-safe logic to meet stringent nuclear safety requirements.

- Proven Environmental Hardening: Undergoes extensive qualification testing to ensure performance during and after design-basis events like earthquakes (seismic) and loss-of-coolant accidents (LOCA), where ordinary industrial components would fail.

- Long-Term Stability and Predictability: Components and materials are selected and aged to ensure performance parameters remain within strict limits over the plant’s multi-decade operational lifespan, minimizing drift and unplanned maintenance.

- Complete Quality Assurance and Traceability: Every module has full traceability from raw materials to final test results, manufactured under a certified NQA-1 quality program. This documentation is mandatory for regulatory compliance.

- Seamless System Integration: Designed as a plug-compatible component within a specific Westinghouse I&C system architecture, ensuring correct mechanical, electrical, and functional integration within the licensed plant design.

Application Cases in Various Fields

- Reactor Protection System (RPS): Could function as a bistable processor comparing neutron flux levels to setpoints, initiating a reactor trip if limits are exceeded.

- Engineered Safety Features Actuation System (ESFAS): May process signals to actuate safety injection pumps, containment spray valves, or emergency diesel generators following a safety signal.

- Core Monitoring System: Might condition signals from in-core neutron detectors or thermocouples for core power distribution and temperature monitoring.

- Radiation Monitoring: Could interface with area radiation monitors to process dose rate signals for alarm and display.

Comparisons with Competing Products

In the nuclear safety I&C domain, direct “competition” is not with commercial products but with alternative sourcing or architectural approaches.

- Vs. Commercial Off-The-Shelf (COTS) Industrial I/O or PLC Cards: COTS components are not qualified for nuclear safety applications. They lack the required environmental testing, rigorous failure mode analysis, and quality assurance pedigree. The 5X00058G01 is in a separate class entirely.

- Vs. Other Nuclear I&C Vendor Components (Framatome, GE Hitachi): These companies have their own qualified components for their reactor platforms. The 5X00058G01 is specific to Westinghouse-designed plants. The alternative is not a competitor’s part but sourcing the correct, qualified Westinghouse part.

- Vs. Modern Digital Upgrades: Plant modernization projects often replace older analog systems (using modules like the 5X00058G01) with fully digital, programmable systems. The comparison is between maintaining the original licensed hardware and undergoing a major system replacement and relicensing effort.

- Key Differentiator: Its primary value is as a certified, traceable component within the plant’s licensed design basis. There is no equivalent substitute without a complex and costly equivalence evaluation process approved by the nuclear regulator.

Selection Suggestions and Precautions

- Mandatory Exact Part Number Replacement: The WESTINGHOUSE 5X00058G01 part number is a controlled design document. Replacement must be with the exact part number and compatible hardware/software revision. No substitution is permitted without formal engineering and regulatory approval.

- Procurement from Approved Sources Only: This component must be purchased through Westinghouse’s official parts supply chain or from suppliers explicitly approved under the plant’s 10 CFR 50 Appendix B / ASME NQA-1 quality assurance program. Unapproved sources pose unacceptable risk.

- Handling with ESD Protection: Treat as an electrostatic discharge (ESD)-sensitive device. Use proper grounding straps and anti-static packaging and procedures during all handling.

- Installation by Qualified Personnel: Installation must be performed by technicians qualified on the specific system, following approved plant procedures under a detailed work package that includes post-maintenance testing.

- Pre-Installation Verification: Before installation, verify the health of the associated chassis, backplane, and power supply. Also, confirm the module’s firmware or configuration (if applicable) matches the system requirements.

- Post-Replacement Testing and Documentation: After installation, perform all prescribed verification tests, which may include loop checks, functional tests, and system-level integration tests. Update all plant documentation to reflect the new component’s serial number and installation date.

- Lifecycle and Obsolescence Planning: Engage with Westinghouse on the lifecycle status of this component. For long-term operation, plan for strategic spares and evaluate eventual system modernization as part of the plant’s lifecycle management strategy.

IC693CPU366 GE PLC

IC693CPU367 GE PLC

IC694MDL645 GE PLC

IC694MDL646 PLC

GE IC693CPU370 PLC

IC694MDL648 GE

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922