Description

Product Description

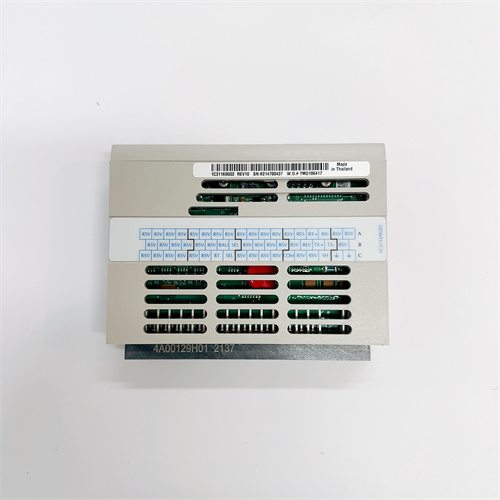

The WESTINGHOUSE 1C31107G01 is a critical system module from the Westinghouse WDPF (Westinghouse Distributed Processing Family) and early Ovation distributed control systems. This component is a WDPF I/O Processor Module, also known as a Drop Processor (DP), which serves as the intelligent interface between the WDPF data highway (Westnet) and a cluster of field I/O modules. The 1C31107G01 functions as a local controller, managing data acquisition from input modules and executing output commands for a specific section or “drop” of the plant. Integrating the Westinghouse 1C31107G01 drop processor is fundamental to the architecture of a WDPF system, enabling distributed control and data processing.

Product Parameters and Specifications

- Product Type: I/O Processor / Drop Processor Module for WDPF.

- Compatible Systems: Westinghouse WDPF and early Emerson Ovation DCS.

- Primary Function: Acts as a local controller for a WDPF I/O drop, executing control logic, scanning I/O, and communicating with the system’s peer-to-peer network (Westnet).

- Communication Interface: Connects to the WDPF Westnet data highway for peer-to-peer communication with other drops and the operator stations.

- Local I/O Bus: Manages a local cluster of WDPF I/O cards (analog input, digital input, etc.) within its own drop cabinet via a proprietary parallel bus.

- Processing Power: Contains its own microprocessor and memory to execute pre-configured control algorithms and logic for the assigned drop, reducing the load on central supervisory computers.

- Configuration: Programmed and configured using Westinghouse-specific engineering tools to define I/O mapping, control strategies, and communication parameters.

- Redundancy: Often deployed in redundant (primary/backup) pairs for high availability in critical applications.

Advantages and Features

- Distributed Control Architecture: The WESTINGHOUSE 1C31107G01 is the cornerstone of WDPF’s distributed processing model. By placing processing power locally at each I/O drop, it enhances system responsiveness, reduces data highway loading, and improves overall system reliability compared to centralized architectures.

- Peer-to-Peer Communication: Enables direct data exchange between different drops on the Westnet without requiring intervention from a central computer. This facilitates fast, efficient coordination between different parts of the plant (e.g., between boiler control and turbine control drops).

- High Availability through Redundancy: Designed for deployment in fault-tolerant redundant configurations. A failed primary 1C31107G01 module can be automatically and seamlessly replaced by its backup partner, ensuring continuous process control.

- Local Execution of Critical Logic: Critical control loops and interlock logic are executed directly within the drop processor. This ensures deterministic performance and continued operation even if communication with higher-level systems is temporarily lost.

- Proven Reliability in Demanding Environments: As a core component of one of the industry’s most robust legacy DCS platforms, this module was engineered for 24/7 operation in critical applications like power generation, with a strong track record for longevity.

Application Cases in Various Fields

- Fossil Fuel Power Generation (WDPF Systems): Served as the drop processor for critical subsystems such as the burner management system (BMS), turbine control, or boiler feedwater control in coal and gas-fired power plants.

- Nuclear Power Plant Non-Safety Systems: Used in balance-of-plant control systems (e.g., cooling water, auxiliary power) in nuclear facilities utilizing WDPF technology.

- Chemical and Process Industries: Managed process units (reactors, distillation columns) as independent but communicating drops within a large plant-wide WDPF DCS.

- Water and Wastewater Treatment: Controlled individual treatment processes (clarification, filtration) as separate, intelligent drops within a centralized supervisory system.

Comparison with Competing Products

- vs. Centralized DCS Architectures: Older DCS systems used central computers for all control. The distributed WDPF with 1C31107G01 processors offered superior scalability, fault tolerance, and performance by distributing the processing load.

- vs. Modern DCS Remote I/O Controllers (e.g., Emerson Ovation C Series): Modern systems continue the distributed model but with more powerful, standardized hardware and software. The 1C31107G01 represents the earlier generation of this concept, with proprietary hardware and a different engineering environment.

- vs. PLC Networks: A network of PLCs can achieve distributed control, but the WDPF system with 1C31107G01 was a more tightly integrated, homogeneous system with native peer-to-peer communication and a unified configuration approach from a single vendor.

Selection Suggestions and Precautions

- Exclusively for Legacy System Support: This module is only for maintaining, repairing, or understanding existing Westinghouse WDPF installations. It is not for new designs or other control systems.

- Stringent Compatibility Verification: The 1C31107G01 must match the specific WDPF system generation, Westnet version, and I/O card types in its drop. Cross-reference the part number with your system’s original Bill of Materials (BOM) and engineering drawings.

- Requires Specialized Knowledge: Configuration, troubleshooting, and programming of WDPF drops require training on obsolete Westinghouse engineering workstations and software tools. This expertise is now highly specialized.

- Redundant Pair Configuration: For any operational system, these processors should be installed and configured as a redundant pair. Operating with a single module poses a significant risk to process availability.

- Obsolescence and Spare Parts: As a legacy component, sourcing genuine, tested spare modules is challenging. Plan for lifecycle management, which may include finding reputable surplus suppliers or considering a system migration strategy.

5501-510 DCS

8230-827 DCS

8230-840 DCS

5503-173 DCS

8230-841 DCS

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922