Description

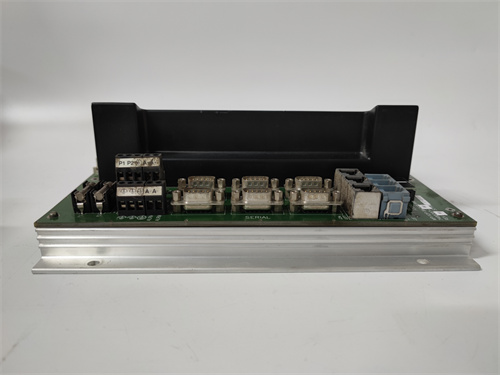

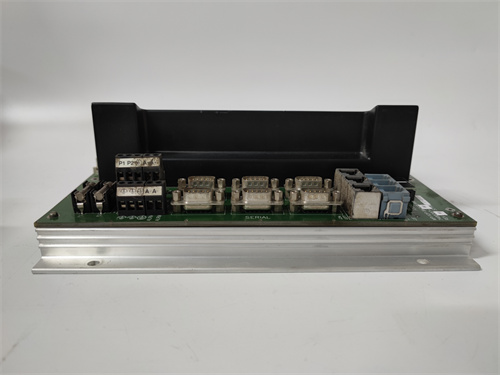

Triconex TriCore+ 2101/4211

The Triconex TriCore+ 2101/4211 is a highly reliable and redundant Programmable Logic Controller (PLC) designed for safety-critical applications in various industries. It utilizes a triple-modular redundant (TMR) architecture ensuring continuous operation even in the event of component failure. This robust system is a cornerstone of Triconex’s safety instrumented systems (SIS), providing unparalleled levels of protection and operational integrity. The Triconex TriCore+ 2101/4211 offers enhanced processing power and advanced communication capabilities compared to previous generations. The specific model numbers (2101 and 4211) denote different I/O capacities and processing capabilities, enabling flexible solutions for diverse project requirements. The Triconex TriCore+ system offers exceptional performance and safety features that are paramount in process safety applications.

Product Description

The Triconex TriCore+ 2101/4211 is a high-availability, safety-certified PLC system built on a triple modular redundant (TMR) architecture. This means that three independent processors continuously compare their outputs. If one processor fails, the system continues to operate seamlessly with the remaining two, eliminating single points of failure. This architecture significantly enhances system reliability and prevents unexpected shutdowns. This ensures uninterrupted operation in critical processes and minimizes the risk of safety incidents. The Triconex TriCore+ 2101/4211 integrates seamlessly with other Triconex safety components, forming a comprehensive safety instrumented system (SIS). The modular design allows for scalability to meet changing application requirements. The system utilizes advanced diagnostics to detect and report potential issues, ensuring proactive maintenance and minimizing downtime. A key benefit of the Triconex TriCore+ 2101/4211 is its certification to meet stringent safety standards, including IEC 61508 and other relevant industry standards.

Product Parameters

| Parameter | Value |

|---|---|

| Processor Type | TriCore+ |

| Redundancy | Triple Modular Redundant (TMR) |

| I/O Capacity (2101) | Varies depending on configuration |

| I/O Capacity (4211) | Higher than 2101, varies depending on config |

| Communication | Ethernet, Profibus, etc. (various options) |

| Safety Certifications | IEC 61508, SIL 3 capable |

| Power Supply | 24 VDC (typical), specifics vary by config |

| Operating Temperature | 0°C to 55°C (typical), consult specifications |

Advantages and Features

- Triple Modular Redundancy: Ensures high availability and reliability.

- Safety Certification: Meets stringent safety standards like IEC 61508.

- Scalability: Modular design allows for easy expansion.

- Advanced Diagnostics: Enables proactive maintenance and minimizes downtime.

- Seamless Integration: Works seamlessly with other Triconex safety components.

- High Processing Power: Handles complex control algorithms efficiently.

Application Areas and Case Studies

The Triconex TriCore+ 2101/4211 finds widespread application in industries demanding high safety and reliability. Examples include:

- Oil and gas refineries: Ensuring safe and efficient operation of critical processes.

- Chemical plants: Preventing hazardous chemical releases.

- Power generation: Safeguarding power plant operations.

- Mining: Protecting workers and equipment in potentially hazardous environments.

Case studies showcase successful implementations in diverse industries, highlighting improved safety, reduced downtime, and increased efficiency. Specific case studies are available upon request.

Competitor Comparison

Compared to other safety PLCs, the Triconex TriCore+ 2101/4211 excels in its robust TMR architecture, comprehensive safety certifications, and seamless integration with a complete safety system ecosystem. While other PLCs may offer similar functionality, the Triconex system often provides superior reliability and safety levels, particularly for the most critical applications. A detailed competitor comparison can be provided based on specific competing systems.

Selection Advice

The choice between Triconex TriCore+ 2101 and Triconex TriCore+ 4211 depends primarily on the required I/O capacity and processing power for the specific application. Consult with our experts to determine the optimal model based on your project’s unique needs.

Precautions

Ensure proper installation, configuration, and maintenance according to the manufacturer’s specifications. Regular preventative maintenance is crucial for optimal performance and safety.

We are your trusted partner, providing Triconex TriCore+ 2101/4211 and other automation spare parts sales and technical support. We offer special discounted prices. Contact us, and we will be happy to serve you.

TRICONEX+2101 4211

METSO IOP320

GE IC697ALG440

METSO IOP320

A-B 1747-L551

ABB UFC921A101

A-B 22C-D045A103

A-B 22C-D045A103

A-B 22C-D045A103

A-B 1336E-EN2

A-B 1756-EN2TR

BENTLYNEVADA 3300/20-12-01-03-00-00

A-B 1756-EN2TR

A-B 1756-EN2TR

LEUZE DDLS 200/200.2-60

WESTINGHOUSE 5X00497G01

SIEMENS 6ES7352-5AH11-0AE0

Emerson 1C31232G02

PILZ 301120

HIMA F3236

PROSOFT MVI56-MNET

Bachmann AI204/2

ABB NDBU-95C

BENTLY 3500/05-01-01-00-00-01

EMERSON PSM-E20

ABB D674A906U01

FANUC A06B-6096-H116

GE UR8FH

EPRO PR9376/010-011

GE DS3800XAIB1E1E6BA05

A-B 1756-EN2T

TRICONEX 8312

GE UR8FH

ABB SDCS-CON-4

A-B 1756-EN2TR

GLENTEK SMC9915-501-000-10-1

A-B 1769-L33ER

FUJI FRN22G1S-4C

WOODWORD 9907-205

YASKAWA CIMR-HB4A0045ABC

ABB SNAT633PAC

EMERSON A6110

Allen-Bradley 1746SC-IN04I

KINETROL 074-040EL000

TRICONEX 2291

ABB NDBU-95C

A-B 2711-K6C10

GE ME98MBP001

A-B 2711-K6C8

TRICONEX 8312

ABB 5SHX1445H0001

A-B 1747-L552

A-B 1756-L61

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922