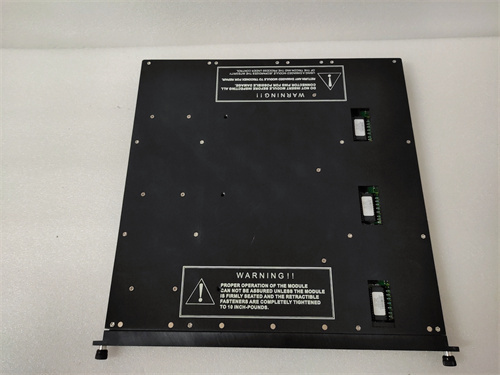

Description

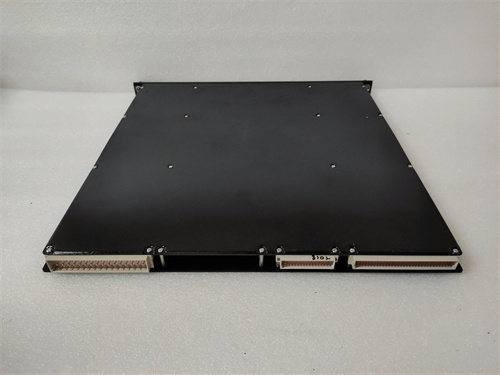

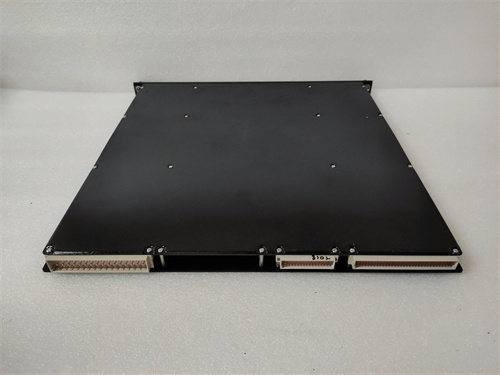

TRICONEX HCU3805E is a flagship triple modular redundant (TMR) safety controller developed by TRICONEX (a division of Schneider Electric), designed to serve as the core of safety instrumented systems (SIS) in high-risk industrial environments. Engineered to deliver SIL 3 safety compliance—the highest level for industrial safety—this controller executes critical safety logic, emergency shutdown (ESD), and process interlock functions with unparalleled reliability. Trusted for its fault-tolerant TMR architecture, fast processing speed, and seamless integration with TRICONEX I/O modules, TRICONEX HCU3805E is the backbone of safety systems in oil & gas, petrochemical, nuclear, and chemical industries. Whether protecting refineries from overpressure incidents, preventing chemical reactor runaway, or ensuring offshore platform safety, TRICONEX HCU3805E provides the ultimate safeguard for personnel, equipment, and the environment.

Core Technical Specifications

| Category | Details |

|---|---|

| Device Type | TMR safety controller for safety instrumented systems (SIS) |

| Core Function | Safety logic execution, emergency shutdown (ESD), process interlock, fault diagnosis |

| Safety Rating | IEC 61508 SIL 3 certification, TÜV approved |

| Architecture | Triple modular redundant (TMR) with 2-out-of-3 (2oo3) voting logic |

| Processing Speed | 1.2 GHz multi-core processor; basic instruction execution ≤ 0.05 ms/step |

| Memory Capacity | 8 GB flash memory, 4 GB RAM (expandable) |

| Communication Interfaces | PROFINET IO, Ethernet/IP, Modbus TCP, TRICONEX TMR Bus, OPC UA |

| I/O Compatibility | TRICONEX 3723X (AI), 3503E (AO), 3625 (DI) I/O modules; third-party SIL 3 devices |

| Power Supply | 24V DC (18-32V DC wide voltage range); dual redundant power inputs |

| Operating Temperature | -40℃ ~ +70℃ |

| Protection Class | IP20 (cabinet mounting) |

| Mounting Type | DIN rail or TRICONEX standard rack mounting |

| Dimensions (L×W×H) | 170mm × 220mm × 30mm |

| Certifications | CE, UL, CSA, ATEX Zone 2, IEC 61508 SIL 3, RoHS |

Key Advantages & Features

1. SIL 3 TMR Architecture: Zero Single-Point Failure

TRICONEX HCU3805E employs a triple modular redundant (TMR) design, with three identical independent processing channels operating in parallel and voting via 2oo3 logic. If one channel fails, the remaining two maintain full safety functionality—eliminating single-point failure risks and ensuring compliance with SIL 3 standards. The controller automatically detects faulty channels, triggers alarms, and allows hot-swap replacement without system shutdown, maximizing availability and minimizing downtime.

2. Ultra-Fast Processing & Real-Time Response

Equipped with a 1.2 GHz multi-core processor, TRICONEX HCU3805E delivers lightning-fast logic execution (≤ 0.05 ms/step) and millisecond-level emergency response. For critical events like overpressure or fire detection, the controller initiates ESD sequences in < 50 ms—providing vital time to mitigate hazards. Its high-speed communication interfaces (up to 1 Gbit/s) ensure real-time data exchange with I/O modules and upstream systems, supporting time-sensitive safety interlocks.

3. Rugged Design for Harsh Industrial Environments

Built to withstand extreme operating conditions, TRICONEX HCU3805E operates reliably from -40℃ (arctic cold) to +70℃ (high-temperature plants). It resists vibrations up to 15G and shocks up to 25G, while its conformal-coated circuit board protects against humidity (95% non-condensing), dust, and chemical vapors. The dual redundant power supply (18-32V DC) accommodates unstable grids, making it ideal for remote oilfields, offshore platforms, and desert refineries.

4. Seamless Integration & Multi-Protocol Flexibility

The controller integrates seamlessly with TRICONEX TMR I/O modules (e.g., 3723X analog input, 3625 digital input) and supports industry-standard protocols (PROFINET IO, Ethernet/IP, Modbus TCP, OPC UA). This flexibility enables integration with third-party SIL 3 sensors, actuators, and DCS systems (e.g., ABB AC 800M, Siemens S7-1500), simplifying retrofits and mixed-vendor system designs. It also supports secure remote monitoring via OPC UA, enabling centralized safety system management.

5. Advanced Diagnostics & User-Friendly Maintenance

TRICONEX HCU3805E features comprehensive built-in diagnostics, monitoring channel health, communication links, and power status in real time. Fault data is logged and transmitted to the TRICONEX TriStation 1131 programming software, allowing technicians to quickly identify and resolve issues. Front-panel LED indicators provide at-a-glance status of power, channel operation, and alarms, while hot-swap capability enables module replacement without system downtime—reducing maintenance costs and operational disruption.

Application Scenarios & Case Studies

1. Oil & Gas: Offshore Platform Emergency Shutdown System

An offshore oil production platform deployed TRICONEX HCU3805E as the core of its ESD system, connecting 128 TRICONEX I/O modules to monitor gas detection, wellhead pressure, and fire suppression systems. During a gas leak incident, the controller’s 2oo3 voting logic ensured reliable detection (even with one faulty gas sensor channel) and triggered an ESD sequence in 45 ms—shutting down wells, isolating pipelines, and activating fire suppression. This rapid response prevented an explosion, protecting 150 personnel and avoiding $2.5 million in equipment damage and environmental cleanup costs.

2. Petrochemical: Reactor Runaway Prevention

A large petrochemical plant used TRICONEX HCU3805E to control 8 ethylene polymerization reactors, executing safety interlocks for temperature, pressure, and catalyst flow. The controller’s fast processing speed detected a 5℃ over-temperature spike in one reactor and triggered an immediate catalyst shutdown and coolant injection—preventing a reactor runaway. The TMR architecture ensured the safety action was executed even when one processing channel failed, avoiding a catastrophic release of hazardous materials and $1.8 million in production losses.

3. Nuclear: Waste Treatment Facility Safety Control

A nuclear waste treatment facility integrated TRICONEX HCU3805E into its SIS, monitoring radiation levels, tank levels, and pump operations. The controller’s SIL 3 certification met strict nuclear safety regulations, while its rugged design withstood the facility’s high-radiation, high-humidity environment. During a power fluctuation (19-29V DC), the dual redundant power supply maintained stable operation, ensuring uninterrupted safety monitoring and avoiding non-compliance penalties of $500,000.

Competitor Comparison

| Comparison Dimension | TRICONEX HCU3805E | Competitor (e.g., HIMA F8621) |

|---|---|---|

| Safety Architecture | TMR (2oo3 voting) | 1oo2D dual redundant |

| Processing Speed | ≤ 0.05 ms/step | ≤ 0.1 ms/step |

| Safety Rating | SIL 3 | SIL 3 |

| Communication Protocols | PROFINET, Ethernet/IP, Modbus TCP, OPC UA | PROFINET, Modbus TCP |

| Operating Temperature | -40℃ ~ +70℃ | -20℃ ~ +60℃ |

| Hot-Swap Support | Full (channels + I/O) | Limited (I/O only) |

| Third-Party Compatibility | Wide (SIL 3 devices) | Limited (proprietary ecosystem) |

Selection Recommendations & Usage Notes

Selection Recommendations

- SIL 3 Critical Applications: Prioritize TRICONEX HCU3805E for oil & gas, petrochemical, nuclear, and chemical industries requiring SIL 3 safety compliance (e.g., ESD, reactor control, fire protection).

- Harsh Environment Deployments: Choose for offshore platforms, remote refineries, or high-temperature plants—leveraging its wide temperature range and rugged design.

- Mixed-Vendor Systems: Ideal for installations integrating third-party SIL 3 devices or DCS systems, thanks to multi-protocol support.

- High-Availability Requirements: Select for 24/7 continuous operations where unplanned downtime is catastrophic (e.g., nuclear facilities, offshore production).

Usage Notes

- Installation: Mount in a sealed, temperature-controlled cabinet; maintain ≥10cm spacing from high-power devices to avoid electromagnetic interference. Ensure proper grounding (ground resistance ≤4Ω) for noise immunity.

- Wiring: Use shielded twisted-pair cables for I/O and communication links; separate power and signal cables to prevent cross-interference. Configure redundant power wiring to both input terminals.

- Configuration & Calibration: Program safety logic via TRICONEX TriStation 1131 software; validate logic with SIL verification tools. Calibrate I/O modules annually to maintain measurement accuracy.

- Maintenance: Perform quarterly diagnostics checks via TriStation software; replace faulty channels during scheduled outages (hot-swap allowed for emergency repairs). Update firmware only with TRICONEX-approved versions.

- Spare Parts: Reserve a full controller spare for critical systems; store in a dry, temperature-controlled environment (0-40℃) with periodic power-up testing to ensure readiness.

- HCU3805E

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922