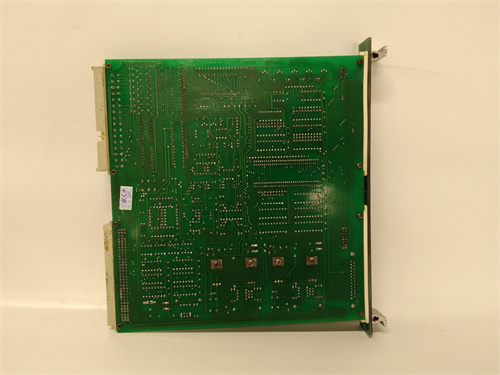

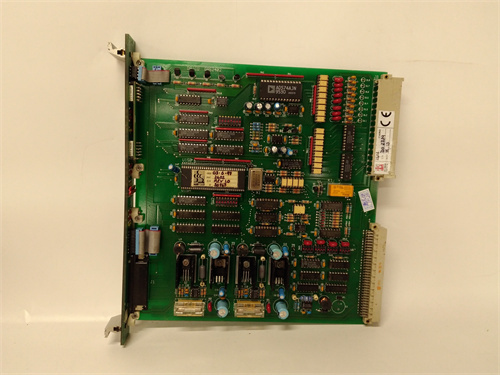

Description

TRICONEX 2402 is a high-density digital input module belonging to Triconex’s flagship Tricon safety instrumented system (SIS) platform, engineered for critical industrial applications where fail-safe performance and compliance with IEC 61508 and SIL 3 standards are non-negotiable. As a core component of Trident’s safety automation ecosystem, TRICONEX 2402 delivers reliable, fault-tolerant signal acquisition for emergency shutdown (ESD), fire & gas, and burner management systems across oil & gas, chemical, and power generation sectors.

Product Description

TRICONEX 2402 is a 32-channel digital input module designed for 24V DC signals, optimized for use in triple modular redundant (TMR) safety systems. The module features isolated inputs to prevent cross-channel interference and ensure signal integrity in high-noise industrial environments. TRICONEX 2402 integrates seamlessly with Triconex Tricon and Trident controllers, providing redundant signal processing that eliminates single points of failure—critical for maintaining safety and availability in process industries. Each channel on TRICONEX 2402 includes diagnostic monitoring to detect open circuits, short circuits, and signal degradation, with real-time status feedback to the safety controller for immediate fault response. The module’s hot-swappable design allows for replacement without system shutdown, while its compact form factor maximizes I/O density in safety cabinets, reducing panel space and installation costs.

Product Parameters

- Input Type: 32 channels of 24V DC digital inputs (sinking/sourcing configurable)

- Isolation: 500V AC isolation between channels, 1500V AC isolation between module and backplane

- Input Voltage Range: 18–30V DC (operating), 0–5V DC (off-state), 13–30V DC (on-state)

- Response Time: <1ms for signal detection, enabling fast safety system activation

- Redundancy: TMR architecture compatible, with triple modular signal processing

- Diagnostics: Channel-level open/short circuit detection, module health monitoring

- Mounting: DIN rail mounting in Triconex Tricon/Trident safety cabinets

- Operating Temperature: -40°C to +70°C, wide tolerance for harsh industrial environments

- Certifications: IEC 61508 SIL 3, TÜV, ATEX, IECEx, UL 1998 compliant for global safety applications

- Power Consumption: 5W typical, low power draw for redundant systems

- Hot-Swap Capability: Supports live module replacement without system interruption

Advantages and Features

- SIL 3 Safety Certification: TRICONEX 2402 is certified to IEC 61508 SIL 3, making it suitable for the most critical safety functions where a high level of risk reduction is required.

- TMR Redundancy Compatibility: The module integrates natively with Triconex’s TMR architecture, ensuring that signal acquisition and processing remain fault-tolerant even in the event of a single module failure.

- High Channel Density: 32 input channels in a single module maximize I/O density, reducing the number of modules needed in safety cabinets and lowering overall system cost.

- Advanced Diagnostics: Channel-level monitoring for open/short circuits and signal faults provides actionable data for predictive maintenance, minimizing unplanned downtime in safety systems.

- Hot-Swappable Design: TRICONEX 2402 can be replaced while the system is running, eliminating the need for process shutdowns during maintenance and improving operational availability.

- Robust Isolation and EMI Protection: Isolated inputs and reinforced backplane shielding ensure reliable performance in high-electrical-noise environments, such as refineries and chemical plants.

Application Fields & Application Cases

Core Application Fields

- Oil & gas (refinery ESD systems, offshore platform fire & gas detection)

- Chemical processing (reactor safety interlocks, emergency shutdown systems)

- Power generation (turbine protection, boiler safety systems)

- Pharmaceutical manufacturing (sterilization process safety, cleanroom environmental controls)

- Pulp & paper (digester safety systems, black liquor recovery unit protection)

Typical Application Cases

- Offshore Platform Fire & Gas System: A major North Sea offshore oil platform deployed TRICONEX 2402 modules to connect fire detectors, gas sensors, and manual call points to its Tricon safety controller. The module’s high channel density reduced cabinet space by 25%, while its SIL 3 certification ensured compliance with offshore safety regulations. The system’s diagnostic capabilities detected a faulty gas sensor wiring fault before it caused a false alarm, preventing a potential platform shutdown.

- Chemical Plant Reactor ESD System: A European specialty chemical plant integrated TRICONEX 2402 into its reactor emergency shutdown system, using the module to monitor pressure, temperature, and level switches. The TMR architecture and hot-swap capability allowed the plant to perform module maintenance during production, increasing reactor availability by 18% and reducing annual downtime by 30 hours.

- Coal-Fired Power Plant Turbine Protection: An Asian coal-fired power plant used TRICONEX 2402 to acquire vibration, temperature, and oil pressure signals for its turbine protection system. The module’s -40°C to +70°C operating range ensured reliable performance in the plant’s high-temperature turbine hall, while its fast response time (<1ms) enabled immediate shutdown during a bearing temperature anomaly, preventing catastrophic turbine damage.

Comparison with Competing Products

| Aspect | TRICONEX 2402 | Competitor 1 (ABB S800 I/O DI810) | Competitor 2 (Siemens F 3210) |

|---|---|---|---|

| Safety Certification | IEC 61508 SIL 3 | IEC 61508 SIL 2 | IEC 61508 SIL 3 |

| Channel Density | 32 channels | 16 channels | 24 channels |

| Redundancy Support | TMR native | Partial redundancy | TMR compatible |

| Hot-Swap Capability | Yes | No | Yes |

| Operating Temperature | -40°C to +70°C | -25°C to +60°C | -30°C to +65°C |

| Isolation Rating | 500V AC (channel) / 1500V AC (backplane) | 500V AC (channel) / 1000V AC (backplane) | 500V AC (channel) / 1500V AC (backplane) |

Key Competitive Edge: TRICONEX 2402 outperforms competitors with its 32-channel high density, native TMR redundancy, and full SIL 3 certification, making it the most efficient choice for large-scale safety systems. Its hot-swappable design and extreme temperature tolerance also provide a distinct advantage in offshore and remote industrial sites where maintenance access is limited.

Selection Suggestions

- Safety Integrity Level (SIL) Requirement: Choose TRICONEX 2402 for SIL 3 safety applications where the highest level of risk reduction is mandatory; for SIL 2 applications, consider Triconex’s cost-effective 2301 module.

- System Redundancy Needs: Select this module if your safety system requires TMR architecture, as it integrates seamlessly with Triconex Tricon/Trident controllers to eliminate single points of failure.

- I/O Density Requirements: Opt for TRICONEX 2402 in large safety systems (e.g., refinery ESD) to minimize the number of modules and reduce cabinet space and wiring complexity.

- Environmental Considerations: Prioritize this module for offshore, mining, or power generation applications due to its -40°C to +70°C operating range and robust EMI protection.

- Maintenance Accessibility: Use TRICONEX 2402 in process plants where shutdowns are costly, as its hot-swap capability allows for live module replacement without production interruption.

Precautions

- Redundant Wiring Practices: For TMR systems, ensure each input signal is wired to all three redundant TRICONEX 2402 modules to maintain fault tolerance; single-point wiring will compromise redundancy.

- Isolation Compliance: Follow Triconex’s wiring guidelines to maintain channel-to-channel and module-to-backplane isolation; avoid running high-voltage cables alongside signal wiring to prevent EMI interference.

- Module Replacement: When hot-swapping TRICONEX 2402, use an electrostatic discharge (ESD) wrist strap to protect sensitive components, and ensure the replacement module is identical in firmware version to maintain system compatibility.

- Diagnostic Monitoring: Regularly review module diagnostic data to identify wiring faults or signal degradation; address issues promptly to prevent safety system failures.

- Power Supply Stability: Install a redundant, filtered power supply for TRICONEX 2402 modules to ensure stable operation; voltage fluctuations can cause false input signals and diagnostic alarms.

- Configuration Backup: Back up the module’s configuration settings to a secure location; this ensures fast restoration in case of module failure or replacement, minimizing system downtime.

- Safety Compliance: Ensure TRICONEX 2402 is used in accordance with its IEC 61508 SIL 3 certification; do not modify the module or its wiring without prior safety assessment and approval.

IS200EACFG1A GE PLC

IS200ECTBG1A GE

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922