Description

Product Description

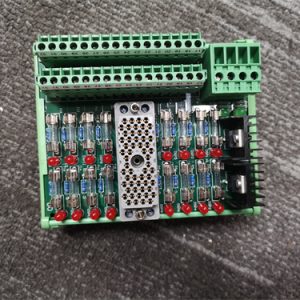

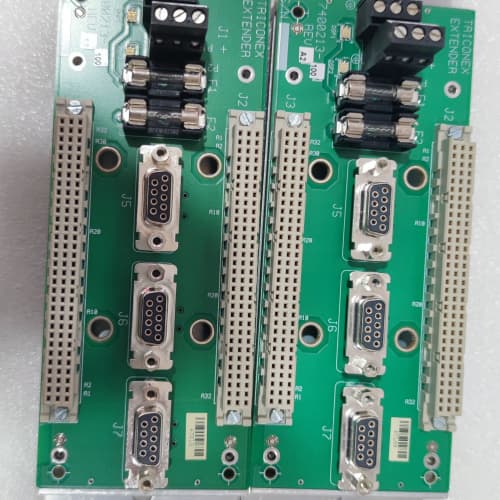

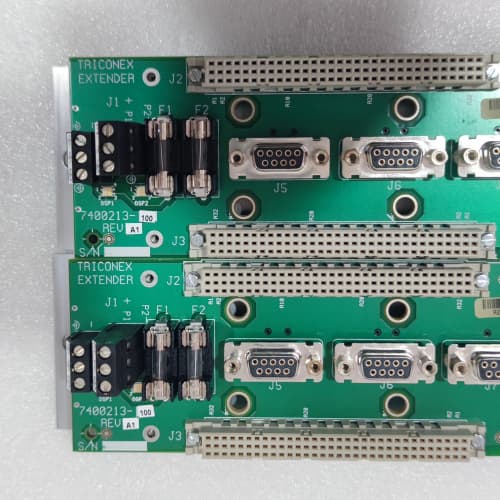

The TRICONEX 09031647921 is a critical component within the Triconex Tricon safety instrumented system (SIS), specifically part of the Tricon v9/v10 or Tricon CX series. This part number identifies a major system module, most likely a Main Processor Module (MPM) or a high-level Communication Module. In a Triple Modular Redundant (TMR) architecture, this module is responsible for executing the application safety logic, managing I/O communications, and/or handling network interfaces with external systems like DCS or engineering workstations. The primary function of the TRICONEX 09031647921 is to provide the high-integrity, fault-tolerant processing power required for Safety Integrity Level (SIL) 3 certified safety applications, such as emergency shutdown (ESD) and fire and gas (F&G) systems. Its design ensures that no single point of failure can compromise the safety function, making it a cornerstone for protecting personnel, equipment, and the environment in hazardous process industries.

Technical Parameters and Features

- Device Type: Main Processor Module (MPM) or Advanced Communication Module for Tricon TMR System.

- Safety Architecture: Part of a Triple Modular Redundant (TMR) system. If a processor, it contains three independent channels that vote on all outputs.

- Primary Function:

- As an MPM: Executes the user-configured safety application program, performs diagnostics, and coordinates with I/O modules. It contains the main CPU and memory.

- As a Comm Module: Provides high-speed communication interfaces (e.g., TriStation network, Modbus, OPC) for system integration and programming.

- Processing & Memory: Features powerful processors (likely PowerPC or similar) and significant memory for application logic and system operation.

- Communication Interfaces: Includes ports for the internal TMR bus (TriBus) and external communication networks. May support:

- TriStation Network for connection to engineering stations.

- Modbus TCP/IP or RTU for DCS/SCADA interface.

- Ethernet for diagnostics and configuration.

- Diagnostics & Redundancy: Performs continuous self-diagnostics and cross-channel checks. Supports hot-swap replacement in redundant configurations to maintain system availability.

- Certifications: Certified for SIL 3 applications according to IEC 61508 and IEC 61511 standards.

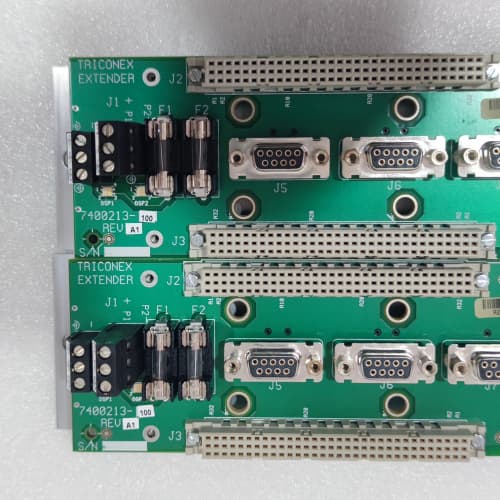

- Form Factor: A large, complex printed circuit board designed to install into a specific slot within a Tricon chassis or rack.

Advantages and Key Features

- Ultimate Safety and Availability: The TMR design of the TRICONEX 09031647921 (if an MPM) ensures both safety and high availability. It can tolerate a failure in any one of its three channels without compromising the safety function, preventing both dangerous failures and spurious trips.

- Powerful Processing for Complex Logic: Capable of executing large and complex safety application programs with high speed, accommodating intricate interlock sequences, calculations, and timing functions required in modern process safety.

- Robust and Secure Communication: Provides reliable, deterministic communication pathways for both internal system coordination and external integration, which is critical for timely safety actions and operator awareness.

- Proven in the Most Critical Applications: Triconex systems are the global standard for process safety. Modules like the 09031647921 have a proven track record of reliability in oil & gas, petrochemical, and power generation applications worldwide.

- Comprehensive Lifecycle Support: As part of the Triconex (now Schneider Electric) ecosystem, it benefits from long-term product support, detailed documentation, and access to specialized engineering tools and services.

Application Case Studies in Various Fields

- Offshore Oil Platform ESD: A TRICONEX 09031647921 Main Processor in a Tricon system executes the platform-wide emergency shutdown logic, processing inputs from wellhead pressure sensors, gas detectors, and manual shutdown stations to safely isolate sections of the platform.

- Refinery Hydrocracker Unit: As the brain of the safety system, it runs the logic that initiates a safe depressurization and shutdown sequence if reactor temperature or pressure exceed safe limits, preventing catastrophic equipment failure.

- Gas Pipeline Compressor Station: Manages permissive and shutdown logic for multiple gas turbine-driven compressors. Its TMR architecture ensures a sensor or module failure does not cause an unnecessary station shutdown that would disrupt pipeline flow.

- Chemical Plant Burner Management System (BMS): Controls the critical start-up, flame monitoring, and emergency fuel cut-off sequences for multiple burners on a furnace, where failure could lead to an explosion.

Comparison with Competing Products

Compared to safety PLCs using dual architecture or general-purpose PLCs programmed for safety, the TRICONEX 09031647921 and the TMR platform offer a distinct philosophy:

- TMR (2oo3) vs. Dual (1oo2D): The TMR architecture provides higher availability alongside safety. A single fault in a dual system often causes a shutdown. In a TMR system with a module like the 09031647921, a single fault is masked, allowing operation to continue until maintenance, reducing production losses.

- Dedicated Safety Controller vs. Configured System: The Tricon system, centered on modules like this, is a dedicated safety controller with hardware-based fault tolerance certified as a complete system. Some competing “safety PLCs” are general-purpose hardware with safety-rated software, requiring more extensive validation by the end-user.

- Depth of Diagnostics: The level of internal cross-channel comparison and diagnostics in a TMR system is inherently very high, contributing directly to its high SIL 3 rating and diagnostic coverage.

Selection Advice and Important Notes

- Confirm Exact Module Function and Compatibility: This is critical. The part number 09031647921 must be verified as the correct spare for your specific Tricon model (v9, v10, CX), chassis type, and slot position. Using an incompatible module can cause a system fault or failure to operate.

- Requires Specialized Engineering Tools: Configuration and diagnostics are performed exclusively using the Triconex TriStation 1131 software suite. Access to this software and personnel trained in its use is mandatory.

- Implement Rigorous Change Management: Any changes to the safety application logic or hardware configuration must follow a strict safety lifecycle management process, including impact analysis, testing, and re-validation as per IEC 61511.

- Handle with Extreme ESD Care: The module contains highly sensitive components. Always use proper electrostatic discharge (ESD) precautions—wrist straps and anti-static packaging—during handling and installation.

- Plan for Hot Swap Procedures: While designed for hot-swapping in redundant systems, the procedure must be followed precisely as per the manufacturer’s instructions to avoid disrupting the operating channels. This is not a simple plug-and-play operation.

DAI04 PLC

MDX60A0015-5A3-4-00

IS220PRTDH1A-IS220PAICH1A PLC

NBRA-656C PLC

VT5035-1X PLC

SE3520608830262-AD1 PLCPLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922