Description

Product Description

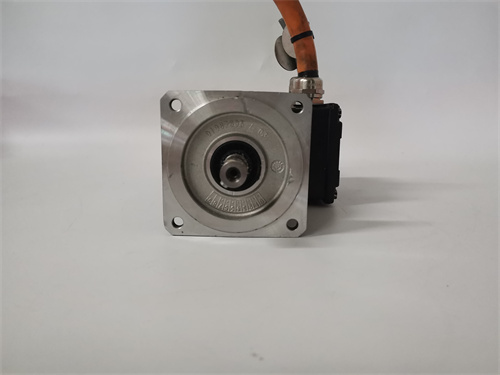

The SEW DFS56L/TF/RH1M/KK is a high-performance, explosion-proof AC brake motor engineered by SEW-Eurodrive specifically for hazardous area applications in chemical processing, oil and gas, pharmaceutical, and grain handling facilities. This specialized motor combines SEW’s field-proven DR series motor platform with ATEX/IECEx certified explosion protection, enabling safe operation in Zone 1/21 and Zone 2/22 hazardous locations. The SEW DFS56L/TF/RH1M/KK integrates multiple specialized features including a built-in holding brake, forced cooling fan, and incremental encoder feedback system into a single compact, certified assembly. Designed for continuous duty in explosive atmospheres, this motor features a rugged cast iron enclosure with flameproof joints exceeding Ex d and Ex tD certification requirements. The SEW DFS56L/TF/RH1M/KK represents SEW’s comprehensive approach to hazardous area automation, providing seamless integration with SEW MOVIMOT and MOVIDRIVE drive controllers for coordinated motion control in safety-critical applications.

Product Parameters

- Model: SEW DFS56L/TF/RH1M/KK

- Product Type: Explosion-Proof AC Brake Motor

- Motor Series: DR63 – DRS/DRE/DFR (DFS56L variant)

- Power Rating: 0.18 kW to 0.37 kW (frame size dependent)

- Voltage: 230/400 V AC, 50/60 Hz, 3-phase

- Speed: 1400–1700 rpm (50 Hz), 1700–2000 rpm (60 Hz)

- Protection Class: Ex d IIC T4 Gb (gas), Ex tD A21 IP65 T135°C (dust)

- Certification: ATEX, IECEx, UL/CSA for Class I Div 1, Class II Div 1

- Brake Type: BE05 – 24 V DC holding brake, spring-applied, electrically released

- Brake Torque: 4.0 Nm (nominal)

- Encoder: RH1M incremental encoder, 1024 pulses/revolution, HTL signals

- Cooling: TF – Forced ventilation, 230/400 V AC independent motor

- Connection: KK – Terminal box with increased volume for hazardous area wiring

- Enclosure Rating: IP65 (standard), IP66 (optional)

- Insulation Class: F (155°C)

- Temperature Rating: -20°C to +40°C ambient

- Mounting: B3 foot mount, B5/B14 flange mount options

- Paint System: Corrosion-resistant, chemical-resistant finish

Advantages and Features

The SEW DFS56L/TF/RH1M/KK delivers exceptional hazardous area compliance through its integrated, system-certified design, eliminating the costly and complex field modifications typically required to adapt standard motors for explosive atmospheres. Unlike general-purpose motors with separate explosion-proof enclosures, the SEW DFS56L/TF/RH1M/KK features factory-certified flameproof joints, encapsulated windings, and specially sealed terminal chambers that maintain certification integrity throughout the motor lifetime. The integrated BE05 holding brake provides fail-safe stopping upon power loss, with spring-applied, electrically released operation achieving 4.0 Nm holding torque in a compact package. The RH1M incremental encoder delivers precise speed and position feedback with 1024 pulses per revolution, enabling closed-loop vector control and precise positioning applications without external feedback devices. The TF forced ventilation system provides constant cooling independent of motor speed, enabling continuous torque output even at zero speed for holding applications. The SEW DFS56L/TF/RH1M/KK ‘s KK oversized terminal chamber provides ample space for hazardous area approved cable glands and internal wiring connections, maintaining required creepage and clearance distances mandated by Ex e increased safety termination requirements. Comprehensive thermal protection includes PTC thermistors embedded in motor windings, directly connected to certified Ex e protection relays for automatic shutdown before temperature limits are exceeded. The motor’s IP65 standard enclosure (IP66 optional) provides complete protection against dust ingress and low-pressure water jets, essential for wash-down environments in pharmaceutical and food processing applications.

Application Cases in Application Fields

- Chemical Batch Reactors: Deployed on agitated reactor vessels in specialty chemical manufacturing, the SEW DFS56L/TF/RH1M/KK provides explosion-proof agitation control with precise speed regulation via RH1M encoder feedback, maintaining consistent mixing energy across varying batch viscosities.

- Offshore Drilling Platforms: Installed on North Sea oil production facilities, this ATEX-certified motor drives chemical injection metering pumps, with the SEW DFS56L/TF/RH1M/KK ‘s IP66 corrosion-resistant enclosure withstanding salt spray and continuous vibration.

- Pharmaceutical Fluid Bed Dryers: Utilized in sterile API manufacturing, the SEW DFS56L/TF/RH1M/KK powers explosion-proof exhaust damper actuators, its smooth enameled paint finish preventing product accumulation and facilitating cleanroom sanitization procedures.

- Grain Elevator Conveyors: Applied in agricultural grain handling facilities, this motor drives enclosed belt conveyors in dust-hazardous areas, with the SEW DFS56L/TF/RH1M/KK ‘s Ex tD A21 certification permitting operation in combustible dust atmospheres.

- Paint Manufacturing: Implemented in solvent-based paint mixing operations, the SEW DFS56L/TF/RH1M/KK provides explosion-proof agitation with controlled acceleration profiles via MOVIDRIVE controller, preventing solvent boiling during rapid speed changes.

Comparison with Competing Products

| Feature | SEW DFS56L/TF/RH1M/KK | ABB Explosion-Proof Motor M3JP | WEG W22X Hazardous Area | Lafert Ex-DX |

|---|---|---|---|---|

| Integrated Brake | Yes (BE05, 4.0 Nm) | Optional (field installed) | Optional (field installed) | Optional (field installed) |

| Integrated Encoder | Yes (RH1M, 1024 PPR) | No | No | No |

| Forced Cooling | Yes (integral TF motor) | No | No | No |

| ATEX/IECEx Certified | Yes (Ex d/Ex tD) | Yes (Ex d/Ex e) | Yes (Ex d/Ex nA) | Yes (Ex d) |

| System Integration | SEW MOVIMOT/MOVIDRIVE native | ABB drives compatible | Universal | Universal |

| Terminal Chamber | KK – oversized, Ex e approved | Standard Ex d | Standard Ex d | Standard Ex d |

| Encoder Feedback | Factory integrated, certified | Requires separate Ex e enclosure | Requires separate Ex d enclosure | Requires separate Ex d enclosure |

| Typical Cost Position | Mid-High | High | Mid | Mid-High |

The SEW DFS56L/TF/RH1M/KK distinguishes itself through its fully integrated, system-certified approach to hazardous area motor control. Unlike ABB, WEG, and Lafert offerings requiring field-installed brakes, encoders, and associated explosion-proof enclosures, the SEW DFS56L/TF/RH1M/KK delivers these features factory-integrated with full certification retention. This integrated approach significantly reduces installation complexity, panel space requirements, and total installed cost despite higher initial component cost. For applications requiring coordinated motion control in hazardous areas, the SEW DFS56L/TF/RH1M/KK ‘s native compatibility with SEW drive systems provides performance advantages unavailable from general-purpose hazardous area motors. While premium-priced compared to standard industrial motors, the SEW DFS56L/TF/RH1M/KK delivers lower total cost of ownership for complex hazardous area applications requiring braking, feedback, and variable speed operation.

Selection Suggestions and Precautions

- Hazardous Area Classification Verification: Confirm that the SEW DFS56L/TF/RH1M/KK certification matches your specific hazardous area classification; Ex d IIC T4 Gb for Zone 1 gas groups IIA, IIB, IIC; Ex tD A21 for Zone 21 combustible dust; Div 1 versions available for North American installations.

- Temperature Class Matching: Verify that the SEW DFS56L/TF/RH1M/KK ‘s T4 temperature class (135°C maximum surface temperature) is appropriate for your application gas group; T4 is suitable for most industrial gases excluding hydrogen (T1) and acetylene (T2).

- Drive System Compatibility: The SEW DFS56L/TF/RH1M/KK integrates optimally with SEW MOVIDRIVE or MOVIMOT drive controllers for encoder feedback processing and brake control; third-party drives require additional interface modules and may not support RH1M encoder signal conditioning.

- Cable Gland Selection: When terminating SEW DFS56L/TF/RH1M/KK in hazardous areas, use only ATEX/IECEx certified Ex e or Ex d cable glands with appropriate entity ratings; standard industrial glands void hazardous area certification and create safety risks.

- Brake Control Requirements: The SEW DFS56L/TF/RH1M/KK BE05 brake requires 24 V DC supply with appropriate rectification and suppression; SEW recommends dedicated brake control modules within MOVIDRIVE drives or external SEW BGE brake rectifiers for optimal performance.

- Thermal Protection Wiring: Connect SEW DFS56L/TF/RH1M/KK PTC thermistors to certified Ex e thermal protection relays with ATEX approval; standard motor overload relays do not provide required hazardous area temperature monitoring certification.

- Forced Cooling Supply: The TF forced ventilation motor requires separate power supply independent of main motor; configure control logic to energize TF cooling whenever main motor is running plus appropriate pre-cooling/post-cooling intervals for high cyclic duty applications.

- Spare Parts Strategy: Given the SEW DFS56L/TF/RH1M/KK ‘s specialized certification and typical lead times of 12–16 weeks for hazardous area products, maintain complete motor spare for each critical application; component-level spares (brake, encoder, fan) require certified installer replacement to maintain Ex certification.

- Environmental Installation: Although IP65 rated, install the SEW DFS56L/TF/RH1M/KK with drip shields in outdoor applications and maintain adequate clearance around TF fan intake; restricted airflow causes thermal overload and premature motor failure.

- Periodic Certification Verification: Implement scheduled inspection of SEW DFS56L/TF/RH1M/KK flameproof joints, cable gland integrity, and enclosure seals per IEC 60079-17 requirements; damage to Ex d flamepaths from improper maintenance is a leading cause of certification invalidation.

- Encoder Signal Integrity: The RH1M encoder produces HTL (high-threshold logic) signals suitable for industrial drives; maximum cable length between SEW DFS56L/TF/RH1M/KK and drive controller is 100 meters unshielded, 300 meters with proper shielding and termination.

- Storage Requirements: Store spare SEW DFS56L/TF/RH1M/KK motors in clean, dry environments at +10°C to +30°C; long-term storage requires periodic shaft rotation (monthly) to prevent bearing brinelling and lubrication migration.

- Nameplate Documentation: Maintain clear photographs of SEW DFS56L/TF/RH1M/KK certification nameplates in maintenance records; Ex d flamepath dimensions and certification numbers are required for regulatory inspections and insurance surveys.

- Commissioning Verification: Prior to hazardous area energization, verify correct rotation, brake release voltage, and TF fan operation; the SEW DFS56L/TF/RH1M/KK ‘s terminal chamber must be properly sealed with certified blanking elements on unused entries to maintain Ex e increased safety certification.

XVME-530 PLC

XVME-653 PLC

XVME-976 PLC

DS200AAHAG2A GE PC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922