Description

Product Description

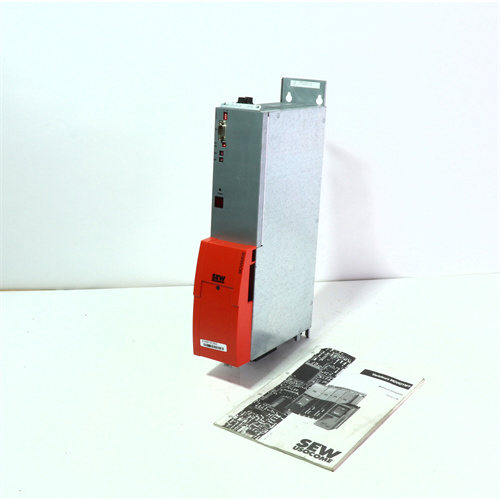

The SEW 31C015-503-4-00 is a compact, sensorless vector control frequency inverter, part of SEW-EURODRIVE’s widely used MOVITRAC or MOVIMOT series of drive controllers. This device is designed to provide precise speed and torque control for standard three-phase asynchronous motors. It converts fixed voltage and frequency from the mains supply into a variable voltage and frequency output, enabling smooth starting, adjustable speed operation, and optimized energy consumption for driven machinery. The 31C015-503-4-00 integrates advanced control functions, I/O, and communication interfaces into a robust housing. Implementing the SEW 31C015-503-4-00 as a motor controller enhances process flexibility, reduces mechanical stress, and improves energy efficiency in a vast range of industrial applications.

Technical Parameters

- Device Type: Compact Frequency Inverter / AC Drive.

- Manufacturer: SEW-EURODRIVE.

- Product Series: MOVITRAC (e.g., B, C, or LTE series) or integrated gearmotor variant.

- Rated Power: Likely 0.75 kW / 1 HP (common for this series, but must be verified by the exact code).

- Input Supply: 3-phase, 380-480V AC, 50/60 Hz.

- Output: 3-phase, 0-480V AC, 0-250 Hz (sensorless vector control).

- Control Features: Sensorless vector control (SLVC) for high starting torque and good speed regulation, V/f control mode, multiple preset speeds, integrated PID controller.

- Integrated I/O: Digital inputs for start/stop/direction/preset speeds, analog input for speed reference (0-10V/4-20mA), relay outputs for status/fault.

- Communication Interfaces: Built-in RS-485 interface for USS or MODBUS RTU protocol. Optional fieldbus cards (PROFIBUS, PROFINET, Ethernet/IP, etc.) can often be added via a slot.

- Protection Features: Overcurrent, overtemperature, motor overload, short-circuit, phase loss, and undervoltage protection.

- Enclosure Rating: Typically IP20 for chassis-mounted units, designed for installation in a control cabinet.

- Cooling: Fan-cooled.

Advantages and Features

- Compact and Integrated Design: The 31C015-503-4-00 packs powerful control logic, I/O, and basic communication into a very space-saving design, ideal for decentralized installation near the motor.

- Excellent Performance with Standard Motors: Its sensorless vector control provides high starting torque (over 150% at 0 Hz) and good speed holding accuracy without requiring a feedback encoder, offering a cost-effective performance boost.

- User-Friendly Configuration: Intuitive parameterization via the integrated keypad with LCD display or via SEW’s MOVITOOLS PC software, which also provides powerful commissioning and diagnostic tools.

- High Reliability and Long Service Life: High-quality components, robust design, and comprehensive protection functions ensure reliable operation in demanding industrial environments, minimizing downtime.

- Seamless System Integration: The built-in RS-485 and expandable fieldbus options allow the SEW 31C015-503-4-00 to be easily integrated into modern automation networks controlled by PLCs from Siemens, Allen-Bradley, or others.

Application Cases in Various Fields

- Conveyor Systems: Speed control for belt, chain, and roller conveyors in material handling, packaging, and logistics.

- Pump and Fan Control: Energy-saving variable speed control for centrifugal pumps and fans in HVAC, water treatment, and building services.

- Mixers and Agitators: Controlling mixing speed for consistent product quality in food & beverage, chemical, and pharmaceutical processes.

- Machine Tools: Drive control for ancillary axes, coolant pumps, and extraction systems.

- Textile and Packaging Machinery: Precise speed synchronization and tension control for winding, unwinding, and processing lines.

Comparison with Competing Products

The SEW 31C015-503-4-00 competes with compact drives in the same power range from manufacturers like Siemens (SINAMICS V20, G120), Danfoss (VLT Micro Drive), and ABB (ACS150, ACS355). Its competitive position is characterized by:

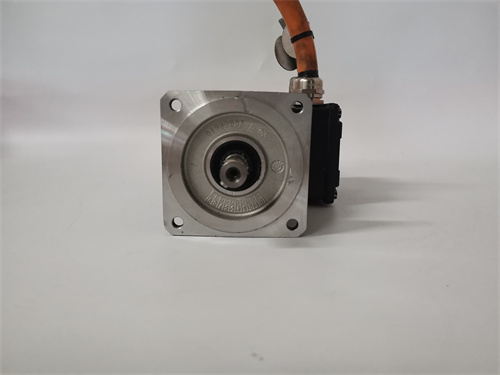

- Strong Mechanical Drive Integration: SEW’s core business is geared motors. The 31C015-503-4-00 is often optimized for and bundled with SEW gearmotors, offering a perfectly matched, single-supplier solution.

- Focus on Usability and Reliability: SEW drives are renowned for their straightforward setup, robust construction, and excellent technical support network, making them a preferred choice for OEMs and end-users seeking a dependable, easy-to-apply component.

- Global Availability and Support: SEW’s extensive global sales and service network ensures good local availability of products like the 31C015-503-4-00 and quick support.

Selection Suggestions and Precautions

- Verify Power and Voltage Match: Confirm the drive’s output power (kW/HP) and voltage range match the connected motor’s nameplate data precisely. Do not oversize or undersize significantly.

- Consider the Application’s Torque Demand: While sensorless vector control provides high start-up torque, verify it meets the breakaway torque requirements of your specific machine (e.g., a loaded conveyor). For extremely high starting torque, an encoder feedback option might be necessary.

- Plan for Proper Cooling and Clearance: Ensure adequate space around the SEW 31C015-503-4-00 in the control cabinet for airflow. Do not install it near significant heat sources. Follow mounting orientation guidelines.

- Implement Correct EMC Practices: Use shielded motor cables, ground the shield properly at both ends (drive and motor), and install line-side EMC filters as recommended to minimize electrical noise emission and ensure stable operation.

- Complete Parameterization and Backup: Do not rely on factory defaults. Carefully set all necessary parameters (motor data, control mode, ramp times, I/O functions) and always save a backup of the complete parameter set to the keypad or MOVITOOLS for quick disaster recovery.

IC660HHM502D PLC

128506 00-128-506 PLC

2711P-K12C4A8 PLC

2711P-RP8A PLC

6SE7023-8TD61 PLC

AKM54G-ANC2R-00-AKM54G-ANC2R-01

128506 PLC

CIMR-VCBA0006BAA

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922