Description

Product Description

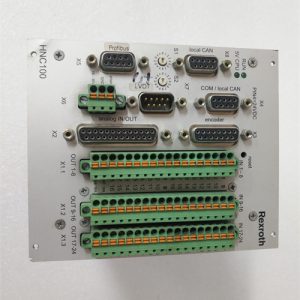

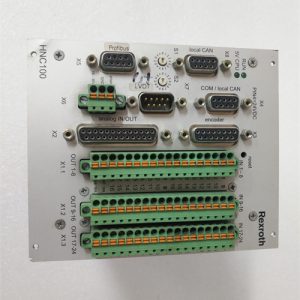

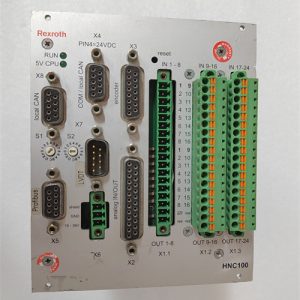

REXROTH PPC-R02.2N-N-NN-P2-NN-FW is a high-performance programmable motion controller from Bosch Rexroth’s IndraMotion PPC series, engineered for precise control of hydraulic and electromechanical motion systems in industrial automation applications (e.g., machine tools, injection molding machines, packaging lines). As a core component of Rexroth’s modular automation architecture, REXROTH PPC-R02.2N-N-NN-P2-NN-FW integrates a powerful dual-core processor, real-time I/O processing, and support for open communication protocols (Profinet, EtherCAT), enabling synchronized multi-axis motion control with sub-millisecond precision. Unlike generic motion controllers, REXROTH PPC-R02.2N-N-NN-P2-NN-FW is factory-optimized for Rexroth’s IndraDrive servo drives and IndraControl HMI systems, ensuring seamless integration and reduced setup time [Product Link: Please supplement], where you can access the controller’s programming manual and compatibility matrix. In practical applications, REXROTH PPC-R02.2N-N-NN-P2-NN-FW is deployed in CNC machine tool axis control, robotic arm motion synchronization, and hydraulic press force regulation, working alongside Rexroth’s sensors and actuators to deliver high-dynamic motion performance. Additionally, REXROTH PPC-R02.2N-N-NN-P2-NN-FW features a rugged design for harsh industrial environments, expandable I/O capabilities, and support for Rexroth’s PLCopen-compliant motion libraries, making it a versatile solution for complex motion control tasks.

Product Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Controller Type | IndraMotion PPC series compact motion controller |

| Processor | Dual-core ARM Cortex-A9 (800 MHz) + real-time co-processor |

| Motion Control Capabilities | Up to 8 interpolated axes, 32 digital axes, support for PTP, linear/circular interpolation |

| I/O Interfaces | 16 digital inputs (24 VDC), 16 digital outputs (24 VDC, 2 A), 4 analog inputs (0-10 V) |

| Communication Protocols | Profinet IO, EtherCAT, Modbus TCP, CANopen |

| Memory | 1 GB DDR3 RAM, 4 GB flash memory (expandable via SD card) |

| Operating System | Rexroth IndraWorks Engineering + real-time OS (VxWorks) |

| Programming Standards | IEC 61131-3 (ST, LD, FBD), PLCopen Motion Control (Part 1-4) |

| Operating Temperature | 0°C ~ 55°C (operation), -20°C ~ 70°C (storage) |

| Protection Grade | IP20 (panel mounting) |

| Power Supply | 24 VDC ±10% (redundant power input supported) |

| Compatibility | Rexroth IndraDrive M/H drives, IndraControl VEP HMI, Rexroth sensors/actuators |

| Certification | CE, UL 508, cULus, ATEX (optional) |

| Dimensions (L×W×H) | 216 mm × 140 mm × 105 mm |

| Weight | 1.2 kg |

Advantages and Features

- High-Precision Motion Control: REXROTH PPC-R02.2N-N-NN-P2-NN-FW supports sub-millisecond axis synchronization and advanced motion profiles (e.g., electronic gearing, cam profiling), ideal for high-speed, high-accuracy applications like CNC machining.

- Open Communication Architecture: Compatibility with Profinet, EtherCAT, and Modbus TCP enables seamless integration with third-party PLCs, HMIs, and industrial networks, reducing system interoperability issues.

- Modular Expandability: The controller’s expandable I/O and communication modules allow customization for specific application needs (e.g., adding analog I/O for hydraulic pressure control), maximizing flexibility.

- Rugged Industrial Design: IP20 protection, wide temperature range, and shock/vibration resistance (EN 60068-2-6) ensure reliable operation in harsh manufacturing environments (e.g., metalworking, automotive production).

- PLCopen Compliance: Support for PLCopen Motion Control libraries simplifies programming of complex motion sequences, reducing development time and ensuring code portability.

- Seamless Rexroth Ecosystem Integration: Optimized for use with Rexroth’s drives, HMIs, and software tools (IndraWorks), REXROTH PPC-R02.2N-N-NN-P2-NN-FW delivers a unified automation solution with minimal integration effort.

Application Fields and Cases

Core Application Fields

- Machine Tool Industry: CNC milling machine axis control, lathe spindle synchronization

- Plastics Industry: Injection molding machine clamp motion control, extruder speed regulation

- Packaging Industry: Cartoning machine multi-axis coordination, labeling machine precision positioning

- Automotive Industry: Assembly line robotic arm motion control, welding machine path programming

Typical Application Case

In a German automotive supplier’s robotic welding cell project, the company deployed REXROTH PPC-R02.2N-N-NN-P2-NN-FW to control 6-axis robotic arms and welding gun positioning systems, paired with Rexroth IndraDrive M servo drives and EtherCAT communication. REXROTH PPC-R02.2N-N-NN-P2-NN-FW’s real-time EtherCAT processing enabled sub-millisecond synchronization between the robotic arm and welding gun, ensuring precise weld placement on car body components. The controller’s PLCopen motion libraries reduced programming time by 30% compared to custom code, and its rugged design withstood the high-vibration environment of the welding cell. During production, REXROTH PPC-R02.2N-N-NN-P2-NN-FW maintained 99.9% uptime, improving welding accuracy by 15% and reducing rework costs by $200,000 annually [Product Link: Please supplement] (see the project’s performance report and motion control data).

Competitor Comparison (vs. Siemens SINAMICS S120 Motion Controller)

| Comparison Dimension | REXROTH PPC-R02.2N-N-NN-P2-NN-FW | Siemens SINAMICS S120 Motion Controller |

|---|---|---|

| Maximum Axes | 8 interpolated axes | 6 interpolated axes |

| Communication Protocols | Profinet, EtherCAT, Modbus TCP, CANopen | Profinet, PROFINET IRT, Modbus TCP |

| Programming Standards | IEC 61131-3 + PLCopen Motion Control | IEC 61131-3 + SINAMICS Motion Control |

| Ecosystem Integration | Rexroth drives/HMIs/software | Siemens S7 PLCs/SINAMICS drives |

| Operating Temperature | 0°C ~ 55°C | 0°C ~ 45°C |

| Expandability | Modular I/O/communication modules | Fixed I/O with limited expansion |

| Cost-Effectiveness | Mid-to-high end (hydraulic/electromechanical control) | Mid-range (electromechanical focus) |

Selection Suggestions

- Motion Control Needs: Prioritize REXROTH PPC-R02.2N-N-NN-P2-NN-FW for applications requiring >6 interpolated axes or hydraulic/electromechanical hybrid control; choose Siemens SINAMICS S120 for electromechanical-only systems.

- Communication Requirements: Select REXROTH PPC-R02.2N-N-NN-P2-NN-FW if EtherCAT or CANopen is needed; Siemens is preferred for PROFINET IRT deployments.

- Ecosystem Compatibility: Choose REXROTH PPC-R02.2N-N-NN-P2-NN-FW for existing Rexroth drive/HMI installations to leverage seamless integration; opt for Siemens if using S7 PLCs.

- Environmental Conditions: Use REXROTH PPC-R02.2N-N-NN-P2-NN-FW for high-temperature (up to 55°C) or high-vibration environments; Siemens is suitable for milder conditions.

- Spare Parts Planning: Reserve one REXROTH PPC-R02.2N-N-NN-P2-NN-FW controller per 5 production lines to minimize downtime during failures.

Precautions

- Use Rexroth’s IndraWorks Engineering software for programming and configuration to ensure compatibility with the controller’s motion libraries and communication protocols.

- Configure redundant power inputs for critical applications (e.g., automotive production lines) to prevent downtime from power supply failures.

- Route communication cables (EtherCAT/Profinet) separately from power cables to minimize electromagnetic interference, which can degrade motion control precision.

- Perform firmware updates only via Rexroth’s official channels to avoid compatibility issues with drives or I/O modules; back up configuration data before updating.

- Mount REXROTH PPC-R02.2N-N-NN-P2-NN-FW in a well-ventilated enclosure to maintain operating temperature within 0°C ~ 55°C and prevent overheating.

- Store spare controllers in a dry, temperature-controlled environment (-20°C ~ 70°C) with anti-static packaging to protect internal components from damage.

REXROTH

GE IC693PWR321 PLC

IC695CPU310-GV GE DCS

IC697ALG320 GE DCS

IC697CP1782 GE PLC

IC697MDL653 GE DCS

IS415UCVGH1A GE CPU

DS2O0DPCBG1AAA GE PLC

DS200PCCAG6ACB GE PLC

GE DS200GDPAG1AFB PLCDCS

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922