Description

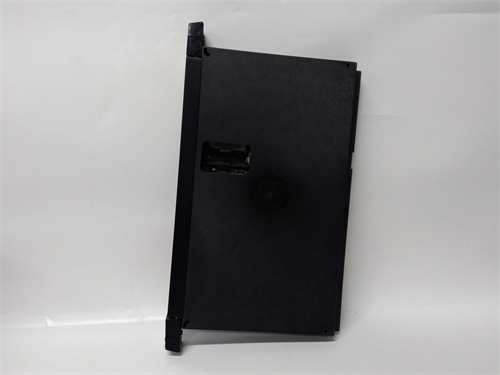

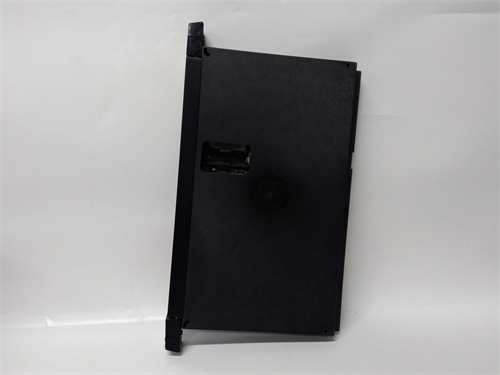

Product Overview and Description

The RELIANCE 57C652 is a high-performance, six-pulse DC drive controller from the Reliance Electric AutoMate D-Series, designed for precise speed and torque regulation of DC motors in industrial applications. This module serves as the intelligent control core, converting three-phase AC line power into a variable DC output to drive motors ranging from fractional to several hundred horsepower. The RELIANCE 57C652 integrates advanced regulation algorithms, I/O interfaces, and communication capabilities into a single package, making it a versatile solution for applications requiring adjustable speed control with high starting torque.

Product Parameters

- Drive Type: Six-Pulse, Non-Regenerative DC Drive Controller.

- Power Range: Typically covers a range within the D-Series, e.g., from 5 HP to several hundred HP (specific range depends on the exact 57C652 variant and associated power stack).

- Input Power: 3-Phase AC, common voltages include 230V, 460V, or 575V AC, 50/60 Hz.

- Output: Variable DC armature voltage and fixed or variable field supply.

- Control Modes: Speed control (with tachometer or armature voltage feedback), Torque (Current) control, and IR Compensation.

- Key Features:

- Firing Circuit: Phase-controlled thyristor (SCR) firing for smooth motor control.

- Feedback Options: Accepts signals from tachogenerators, armature voltage feedback (EMF), or encoder/pulse tachometer.

- I/O Configuration: Includes analog inputs for speed/current reference (e.g., 0-10V, 4-20mA), digital inputs for start/stop/jog, digital outputs for status, and relay contacts.

- Protections: Comprehensive protection against overcurrent, overload, overspeed, overtemperature, and field loss.

- Communications: Optional factory or field-installed communication cards for networks like Remote I/O, DeviceNet, or Modbus.

- Enclosure: Designed for chassis mounting into a user-supplied cabinet or available as part of a complete drive system.

Advantages and Key Features

- Robust DC Motor Control: The RELIANCE 57C652 is engineered specifically for the high starting torque and precise low-speed control characteristics of DC motors, making it ideal for demanding applications like extruders, winders, and conveyors.

- Flexible Configuration: Its extensive array of configurable I/O and feedback options allows the drive to be tailored to a wide variety of applications, from simple speed control to complex tension-regulated systems.

- Proven Reliability: Built with industrial-grade components and a robust thermal design, the RELIANCE 57C652 is known for its durability and long service life in harsh manufacturing environments.

- Advanced Diagnostics: The drive provides detailed fault logging and status information, aiding in rapid troubleshooting and minimizing downtime. LED indicators and software tools offer clear insight into drive operation.

- Seamless System Integration: As part of the Reliance AutoMate family, the RELIANCE 57C652 can be easily integrated with Reliance PLCs and coordinated with other drives on a common network, simplifying overall machine control architecture.

Application Cases in Various Fields

- Plastics Extrusion: Providing precise, constant-torque speed control for the main extruder screw drive motor, ensuring consistent material output and quality.

- Web Handling & Winding: Controlling the speed of a center-wind or surface-wind roll in a paper, film, or converting line, often using a dancer or load cell for tension feedback to the RELIANCE 57C652.

- Material Handling: Driving the main conveyor or haulage motors in mining or bulk handling systems where high starting torque is required to move loaded belts.

- Machine Tool Auxiliaries: Powering the spindle drive on older machine tools or controlling the feed drives where DC motors are still in service.

Comparison with Competing Products

The RELIANCE 57C652 competes with other industrial DC drives from manufacturers like Siemens (SIMOREG), ABB (DCS Series), and Parker SSD (590+). Compared to modern AC variable frequency drives (VFDs), DC drives like the 57C652 offer superior low-speed torque and simpler control for traditional DC motor retrofits. Its primary advantages within its niche are its strong reputation for durability, deep integration with other Reliance control products, and extensive support available for legacy systems. While AC drives have largely become the standard for new installations due to lower motor maintenance, the RELIANCE 57C652 remains a critical component for maintaining and optimizing existing DC motor-based machinery.

Selection Suggestions and Precautions

- Selection Advice:

- Motor Matching: Precisely match the drive’s continuous and overload current ratings to the motor’s nameplate armature and field current. Undersizing will lead to nuisance faults; oversizing may not provide adequate protection.

- Application Requirements: Clearly define whether the application requires simple speed control or more advanced regulation (torque, tension). This determines the necessary feedback devices and drive configuration.

- Power Stack Consideration: The RELIANCE 57C652 controller is typically paired with a specific SCR power module (e.g., 57C653, 57C654). Ensure you are sourcing the correct matched pair for your horsepower and voltage requirements.

- Important Precautions:

- High Voltage Safety: The drive contains lethal AC line and DC bus voltages. Installation, commissioning, and maintenance must be performed by qualified personnel following lockout/tagout procedures.

- Proper Ventilation & Derating: Install the drive in a well-ventilated enclosure. Derating may be required for high ambient temperatures or high altitude. Follow the manufacturer’s thermal management guidelines precisely.

- Dynamic Braking: If rapid stopping is required, an external dynamic braking resistor module must be correctly sized and installed. The base RELIANCE 57C652 is a non-regenerative drive.

- Motor Field Supply: Never interrupt the DC motor’s field supply while the armature is powered, as this can cause a dangerous overspeed condition. Use the drive’s field loss protection feature.

- Parameter Backup: Before making any changes, and after optimal tuning, always back up the drive’s configuration parameters. This is essential for quick recovery after a fault or module replacement.

CSF-14-80 PLC

SR469-P5-HI-A20-H PLC

83SR04C-E DCS

XO08R1-B4.0 PLC

IC697ACC722B PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922