Description

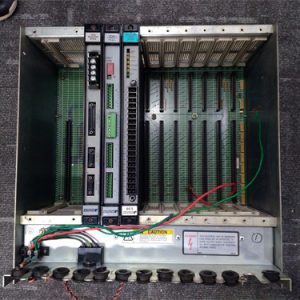

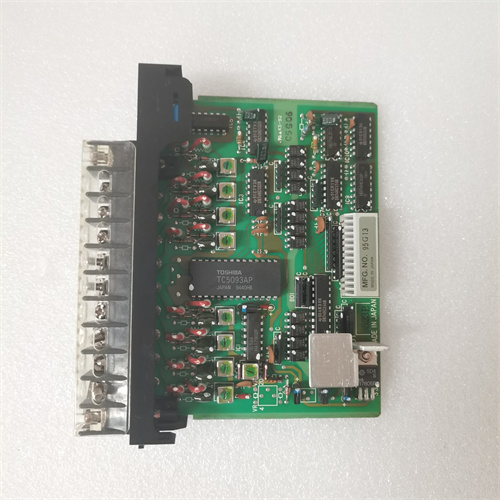

RELIANCE 57C332A Motor Drive Controller

Product Description

The RELIANCE 57C332A is a digital DC drive controller or a critical module from a Reliance Electric variable speed drive system, likely part of their AutoMate or MaxPak series. This component serves as the intelligent control core for regulating the speed, torque, and direction of DC motors in industrial applications. It functions by converting AC line power into controlled DC power for the motor armature and field, executing complex control algorithms to maintain precise motor performance. Engineered for demanding motion control tasks, the RELIANCE 57C332A provides a robust interface between higher-level automation systems (like PLCs) and the motor, enabling sophisticated speed profiling, tension control, and coordinated multi-drive systems. For detailed technical documentation, wiring diagrams, and programming manuals, please visit the official product resource: RELIANCE 57C332A. The integration of the 57C332A controller into a machinery control scheme allows for dynamic and efficient operation of critical processes such as winding, extruding, or conveying. As a key component from a respected manufacturer of industrial motors and drives, the reliability and configurability of the RELIANCE 57C332A make it a trusted choice for legacy and ongoing automation projects requiring precise DC motor control.

Product Parameters

- Product Model: RELIANCE 57C332A

- Manufacturer: Reliance Electric (acquired by Rockwell Automation).

- Device Type: DC Drive Controller / Regulator Module.

- Motor Compatibility: Designed to control DC motors of a specific horsepower (HP) or kilowatt (kW) range.

- Input Power: Specific AC line voltage and phase input (e.g., 230V AC 3-phase, 460V AC 3-phase).

- Control Methods: Typically includes armature voltage control and separate field control (constant torque, constant HP). Supports various modes:

- Speed Control: Using tachometer or armature voltage feedback (IR compensation).

- Torque Control: Using armature current feedback.

- Inputs/Outputs:

- Analog Inputs: For speed/current reference (e.g., 0-10V, 4-20mA) from a PLC or potentiometer.

- Digital Inputs: For run/stop, forward/reverse, fault reset.

- Analog Outputs: For meter outputs (speed, current).

- Digital Outputs/Relay Contacts: For drive status (running, fault) and alarm signaling.

- Communication: May include serial communication options (e.g., Reliance Datalink, Modbus) for integration with PLC networks.

- Protections: Comprehensive motor and drive protection including overload, overcurrent, overspeed, field loss, and overtemperature.

- Programming Interface: Configured via a local keypad/pendant or dedicated programming software.

Advantages and Features

- Precise Speed and Torque Regulation: Offers excellent speed holding accuracy and fast torque response, which is essential for applications like center-driven winders, machine tools, and test stands.

- Robust and Reliable Design: Built with industrial-grade components, these drives are known for their durability and ability to operate in harsh industrial environments with electrical noise and temperature variations.

- Flexible Configuration: Highly programmable for a wide range of applications, allowing customization of acceleration/deceleration ramps, current limits, and feedback loops to match specific motor and load characteristics.

- Strong Diagnostic Capabilities: Provides detailed fault codes and status information, making troubleshooting and maintenance more efficient and reducing downtime.

- Proven Legacy Performance: As part of the extensive Reliance installed base, the 57C332A represents a mature, field-proven technology with deep application knowledge and support available.

Application Cases in Various Fields

- Paper Converting and Printing: Used as the tension regulator on a center-driven winder or unwinder, precisely controlling torque to maintain consistent web tension during rolling.

- Plastics Extrusion: Controls the speed of the extruder screw DC motor, ensuring consistent output and material properties by maintaining precise RPM under varying load conditions.

- Wire Drawing and Cable Machinery: Provides precise speed control for multiple capstans in a multi-motor synchronized system, ensuring uniform wire diameter and tension.

- Mining & Material Handling: Regulates the speed of DC motors on large conveyor belts or bucket elevators, allowing for soft starts and controlled stops to minimize mechanical stress.

Comparison with Competing Products

The RELIANCE 57C332A competes with DC drives from manufacturers like Siemens, ABB, and Parker SSD. Its key historical advantages were its tight integration with Reliance DC motors and its strong reputation in specific industries like converting and extrusion. Compared to modern AC variable frequency drives (VFDs) with vector control, a DC drive like the 57C332A requires more maintenance (brush/commutator on the motor) but can offer superior low-speed torque performance and a simpler control principle for torque regulation. It represents a specialized, high-performance solution for DC motor control, often found in legacy systems or applications where its specific performance characteristics are still valued.

Selection Suggestions and Precautions

- Drive-Motor Match is Critical: The drive must be correctly matched to the DC motor. Verify the motor’s nameplate specifications: armature voltage and current, field voltage and current, and horsepower. An undersized drive will overload; an oversized drive may not protect the motor correctly.

- Feedback System Selection: Determine the required feedback method for speed control (tachometer vs. armature voltage feedback/IR comp). Tach feedback provides higher accuracy but adds cost and complexity.

- Power and Control Wiring Separation: Strictly separate high-power AC/DC wiring from low-voltage control and signal wiring using separate conduits or trays to prevent electrical noise from causing erratic drive operation.

- Dynamic Braking Resistor (if required): For applications requiring rapid deceleration or overhauling loads, an external dynamic braking resistor module must be correctly sized and installed to safely dissipate regenerative energy.

MAM-KY12S CPU

HMS01.1N-W0110-A-07-NNNN

MVI69-PDPS PLC

C32D-CT1V PLC

C16XD-CT1V

2711P-T7C4D7

MPL-B230P-VJ42AA

TA24042-8240-10 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922