Description

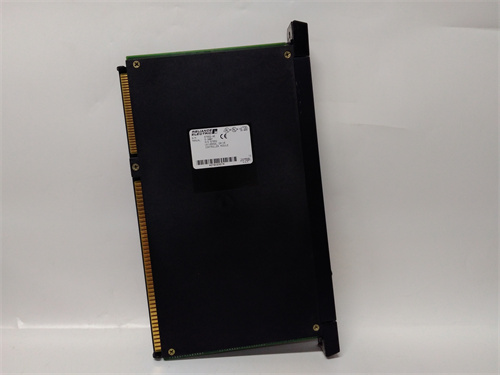

Product Overview and Introduction

The RELIANCE 57552-4 is a specialized I/O module or termination board designed for integration within Reliance Electric’s AutoMate and/or Automax programmable controller systems. This module serves as a critical interface point, facilitating the connection between the PLC’s internal logic and field devices such as sensors, pushbuttons, solenoids, and motor starters. The RELIANCE 57552-4 is engineered to provide reliable signal conversion and electrical isolation within the robust Automax platform, which was renowned for its use in demanding industrial automation applications, particularly in material handling, automotive manufacturing, and heavy industrial processes.

Detailed Product Parameters and Specifications

This module’s functionality is defined by its I/O type and electrical characteristics:

- Primary Function: Digital or Analog I/O Module or a specialized Termination Board for the Automax PLC rack system. The exact function (Input, Output, mixed, or termination) is defined by the specific part number suffix.

- I/O Type & Count: Likely configures as a specific number of points. Common configurations include 16-point or 32-point digital input or output modules, or specialized analog or relay output cards. The “-4” suffix often denotes a specific voltage or configuration variant.

- Voltage Ratings: Designed for standard industrial control voltages. For digital I/O, this is typically 24V DC or 120V AC, depending on the module variant. The rating must be verified against the specific part number.

- Electrical Isolation: Provides optical or transformer-based isolation between the field wiring and the internal PLC logic to prevent noise interference and protect the controller from voltage transients.

- Connection Method: Utilizes a removable terminal block (e.g., Eurostyle or pluggable screw terminal block) for secure and maintainable field wiring connections.

- Status Indicators: Includes LED indicators for each channel to provide visual status (ON for inputs, active for outputs) and diagnostic information (such as a fault LED for the module).

- Backplane Compatibility: Designed to plug into a specific slot within an Automax or related Reliance controller chassis, communicating via the proprietary backplane bus.

- Power Consumption: Draws a specified amount of current from the controller’s backplane power supply, which must be factored into system design.

Key Advantages and Distinctive Features

The RELIANCE 57552-4 module offered distinct benefits within its ecosystem:

- Robust Industrial Design: Built to the high standards of the Automax platform, known for its durability in harsh industrial environments with significant electrical noise, vibration, and temperature fluctuations.

- Seamless System Integration: As a genuine Reliance Electric component, it guaranteed full hardware and software compatibility with the Automax processor, programming software (such as APT or later tools), and the rack’s power distribution, ensuring reliable operation.

- High Density and Organized Wiring: Its design allowed for a high number of I/O points in a single slot, saving panel space. The use of removable terminal blocks simplified wiring, testing, and module replacement.

- Clear Diagnostic Feedback: Per-point and module-level status LEDs enabled rapid troubleshooting of field device issues directly at the rack, minimizing downtime.

- Proven Performance in Legacy Systems: For the extensive installed base of Reliance AutoMate/Automax systems, the 57552-4 represents a critical spare part that extends the operational life of reliable, well-understood control systems. Maintaining system integrity with original modules like the RELIANCE 57552-4 is often more cost-effective than a full control system retrofit.

Application Scenarios and Case Studies

This I/O module was deployed across a wide range of industries that utilized Reliance controllers:

- Automotive Manufacturing: Controlling robotic weld cells, pallet transfer lines, and automated assembly stations in automotive plants.

- Material Handling: Managing complex conveyor sorting systems, automated storage and retrieval systems (AS/RS), and warehouse automation.

- Food & Beverage Processing: Automating packaging lines, palletizing systems, and processing steps where the robust Automax was favored.

- Industrial Machinery: Serving as the I/O interface for custom machine tools, die casting machines, and plastic injection molding machines.

A typical application case involved a large automotive body shop transfer line. Multiple RELIANCE 57552-4 digital input modules were used to read the status of hundreds of proximity sensors confirming fixture clamps were closed and parts were in position. Corresponding output modules controlled solenoid valves to actuate clamps and pushers. The reliability of these I/O modules was critical to maintaining the high cycle time and uptime required for production.

Comparison with Competing Products

In its era, the RELIANCE 57552-4 competed with I/O modules from other major PLC manufacturers like Allen-Bradley (1771 I/O), Siemens (SIMATIC S5), and Modicon (800 series).

- Platform-Specific Performance: Its key advantage was optimized performance and reliability within the Reliance Automax ecosystem, which was particularly strong in complex sequential control and material handling applications.

- System Cohesion: The integration of hardware, networking (DRB/DWB), and programming software created a cohesive, high-performance solution. Competing on a per-module basis was less relevant than the overall system capability.

- Legacy Support Niche: Today, its primary “competition” is against modern replacement PLCs (e.g., Rockwell ControlLogix/CompactLogix, Siemens S7-1500). The 57552-4‘s value is as a sustainment part for legacy systems.

Modern I/O modules offer significantly higher point density, faster communication (EtherNet/IP, PROFINET), more advanced diagnostics, and smaller form factors. However, for maintaining an existing Automax system, only the genuine Reliance module provides a guaranteed fit and function.

Selection Guidelines and Important Considerations

Selecting or replacing this module requires a focused approach on legacy system support:

- Exact System Compatibility Verification: The RELIANCE 57552-4 must be confirmed as the correct module for your specific Automax processor model, rack type, and firmware revision. Consult the original system documentation or configuration printouts.

- Decode the I/O Type: It is imperative to determine if this specific part number is an input, output, or other type of module. Installing a digital input module in a slot configured for an output in the software will cause a fault and will not work.

- Voltage Level Matching: For digital modules, confirm the voltage rating (e.g., 24V DC vs. 120V AC) matches your existing field device wiring and power supply. A mismatch can destroy the module.

- Software Configuration: The module must be correctly configured in the Reliance APT (or equivalent) programming software. The software configuration (rack type, slot, I/O type) must match the physical hardware.

- Handling and Static Protection: Treat as a static-sensitive device. Use proper ESD precautions during handling and installation.

- Wiring and Safety: During installation, ensure all power to the PLC rack and field devices is locked out and tagged out. Carefully label wires before disconnection. When reinstalling, ensure all connections are tight and correct. Always use the official Reliance hardware manual for the 57552-4, which can be found via the product link, for all electrical and mechanical specifications. Given the age of these systems, verifying the health of the rack’s power supply and backplane connectors during module replacement is a recommended best practice.

YPQ110A PLC

FHA-40C-100-E250-C+HA-655-4-200 PLC

HDSF25-160-700089 PLC

DS200DCFBG1BKC

CSF-25-160-2UH-SPK0031 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922