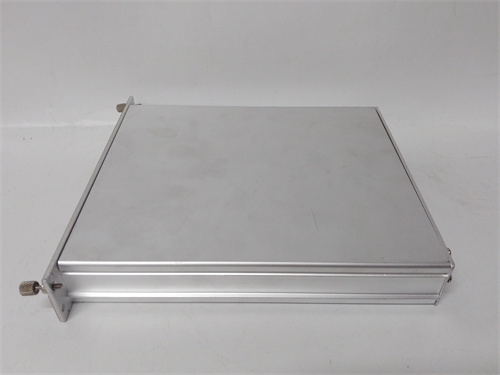

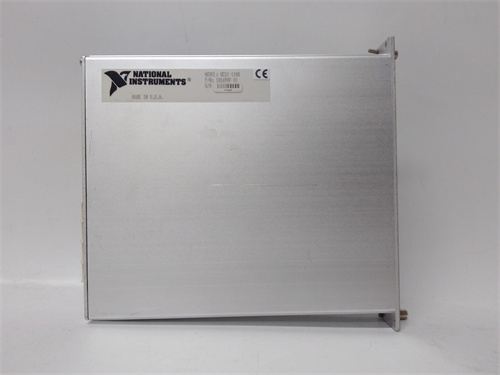

Description

Product Overview

The NI SCXI-1100 is a versatile, high-performance signal conditioning module designed for National Instruments’ SCXI (Signal Conditioning eXtensions for Instrumentation) modular platform. Unlike a traditional PLC I/O card, this module serves as an intelligent front-end for data acquisition (DAQ) systems, primarily when interfacing with a PC-based controller running software like LabVIEW. Its primary function is to provide robust signal conditioning—including amplification, filtering, isolation, and multiplexing—for a wide array of analog input signals before they are digitized by a downstream DAQ device. For detailed technical specifications, configuration guides, and application notes, please visit the official product resource: NI SCXI-1100. The NI SCXI-1100 is a cornerstone for building reliable and accurate measurement systems in test, measurement, and industrial monitoring applications where signal integrity is paramount. Its modular nature allows it to be a key component in a chassis alongside other specialized SCXI modules.

Product Parameters and Specifications

- Function: Multichannel Analog Input Signal Conditioning Module.

- Channels: Configurable for 32 single-ended or 16 differential analog input channels.

- Input Signal Ranges: Software-selectable gains allow for a wide range of input signals, from low-level signals (e.g., ±100 mV) to higher voltages (e.g., ±10 V). It is particularly well-suited for thermocouples, strain gauges (with completion), and general-purpose voltage signals.

- Signal Conditioning Features:

- Programmable Gain Amplifier (PGA): For adapting to different signal levels.

- Filters: Includes software-selectable low-pass filters to reject noise.

- Isolation: Provides channel-to-channel and channel-to-bus isolation to protect the system and eliminate ground loops.

- Excitation Current: Can supply excitation current for resistive bridge-based sensors like strain gauges or RTDs.

- Multiplexing: Channels are multiplexed to a single analog output that connects to a single analog input on a DAQ card (e.g., a PCI/PXI card), enabling high-channel-count systems.

- Connection: Uses an SCXI-style front connector for high-density screw terminal or BNC connector blocks for field wiring.

- Platform: Requires an SCXI chassis for power and communication, and a DAQ device to digitize the conditioned signal.

Advantages and Key Features

The NI SCXI-1100 provides significant advantages for precision measurement. Its primary benefit is superior signal integrity through professional-grade conditioning, which includes isolation and filtering to deliver clean, accurate signals in electrically noisy industrial environments. The high channel density and multiplexing capability make it a cost-effective solution for systems monitoring dozens of sensors. Its software-selectable gain and filtering offer tremendous flexibility, allowing a single NI SCXI-1100 module to handle diverse sensor types within the same system. The module is part of the robust and scalable SCXI ecosystem, ensuring mechanical and electrical compatibility with a wide range of chassis, terminal blocks, and DAQ hardware. Its tight integration with NI-DAQ driver software and LabVIEW simplifies configuration, calibration, and development, reducing system integration time.

Application Cases in Industry

This module is widely used in data-intensive test and monitoring applications. In Automotive Test Rigs, the NI SCXI-1100 conditions signals from thermocouples on engines, strain gauges on components, and pressure transducers. For Aerospace Structural Testing, it acquires data from hundreds of strain gauge channels on airframe prototypes. In Industrial R&D and Product Validation, it serves as the front-end for monitoring environmental chamber sensors, vibration tests, and power quality measurements. While not a control device like a PLC, it is often used in Condition Monitoring systems for critical machinery (pumps, turbines, generators) to acquire high-fidelity vibration, temperature, and pressure data for analysis and predictive maintenance.

Comparison with Competing Products

- vs. Direct-Connect DAQ Cards: Compared to a DAQ card with built-in conditioning, the NI SCXI-1100 offers superior isolation, higher channel density, and dedicated conditioning (like bridge completion) that most cards lack. It is for more demanding measurement scenarios.

- vs. PLC Analog Input Modules: PLC modules (e.g., Siemens SM331) are designed for real-time control with deterministic scan rates. The NI SCXI-1100 is designed for high-accuracy data acquisition and monitoring, often with higher precision and better noise rejection but typically interfaced to a PC, not a real-time controller.

- vs. Other Modular Signal Conditioners: Competitors include data acquisition systems from Keysight (Agilent) or DEWESoft. The NI SCXI-1100 competes on the basis of its deep integration with the NI software ecosystem (LabVIEW, DIAdem), the breadth of the SCXI module portfolio, and strong brand recognition in test and measurement.

Selection Suggestions and Precautions

- Selection Advice:

- Sensor Compatibility Analysis: Match the NI SCXI-1100‘s capabilities to your sensors. Verify it supports the required signal type (thermocouple type, voltage range), provides necessary excitation (for strain gauges/RTDs), and has adequate filtering bandwidth.

- System Architecture Planning: Remember this module requires an SCXI Chassis for power and communication and a DAQ Device (e.g., an SCXI-1600 USB module or a PCI/PXI card) to digitize the signal. Factor in all these components.

- Channel Count and Scanning Rate: While it multiplexes many channels, the aggregate scanning rate is limited by the DAQ device. Ensure the total system scan rate (channels * sample rate) meets your application’s needs.

- Terminal Block Selection: Choose the appropriate screw terminal or BNC accessory module for your wiring needs.

- Important Precautions:

- Proper Grounding and Shielding: To achieve the specified noise performance, follow NI’s guidelines meticulously for sensor grounding, cable shielding, and chassis earth connections. Improper grounding is the most common source of measurement error.

- Calibration: For highest accuracy, the module and the associated DAQ system should be periodically calibrated using traceable standards, especially when used with low-level signals like thermocouples.

- Environmental Limits: Ensure the operating temperature range of the NI SCXI-1100 and its chassis is suitable for the installation environment.

- Software Driver Maintenance: Keep the NI-DAQmx driver software updated for compatibility with your operating system and application software.

ADV151-P00 S2 YOKOGAWA/

ADV551-P00 S2 YOKOGAWA/ OMRON

AAR145-S50 YOKOGAWA/

AAI143-S00 YOKOGAWA/

PW482 YOKOGAWA/

AAI143-H00 YOKOGAWA/

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922