Description

Product Description

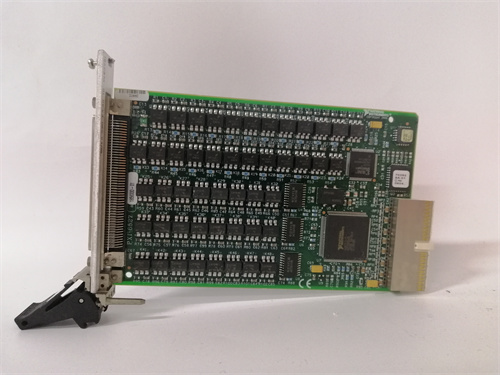

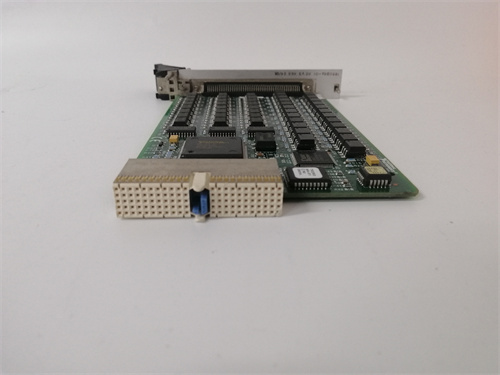

The NI PXI-6527 is a high-performance, high-voltage digital input and output (I/O) module designed for the PXI (PCI eXtensions for Instrumentation) and CompactPCI platforms from National Instruments. This module serves as a critical interface for demanding industrial automation, test, and control applications, bridging the gap between a high-speed PXI controller and real-world industrial signals. The primary function of the NI PXI-6527 is to provide robust, isolated channels for reading the status of high-voltage discrete devices (like limit switches and relays) and for controlling actuators (such as solenoids, contactors, and indicator lamps) in harsh electrical environments. Its design emphasizes both data integrity and device protection, making it a cornerstone for building reliable automated test stands, manufacturing test systems, and real-time control applications. Integrating the NI PXI-6527 into a PXI system enables engineers to leverage the platform’s fast bus speeds and deterministic software tools for precise, synchronized control and measurement of industrial processes.

Technical Parameters and Features

- Device Type: High-Voltage/Industrial Digital I/O Module for PXI/CompactPCI.

- I/O Configuration: Typically provides a combination of digital input and output channels. A common configuration is 8 isolated input channels and 8 isolated output channels, but the specific count for the PXI-6527 should be verified.

- Voltage Ratings:

- Input Channels: Designed to read high-voltage signals, typically up to 60 VDC, with programmable thresholds (e.g., for 5V, 12V, or 24V logic).

- Output Channels: Provide isolated switching for industrial loads, typically supporting voltages up to 60 VDC and currents up to several hundred mA per channel.

- Isolation: Channels are individually isolated from each other and from the PXI bus (often at 500 VDC or higher). This is a critical feature that prevents ground loops, protects the sensitive PXI chassis from voltage transients, and allows each channel to reference different ground potentials.

- Connector: Uses a high-density, screw-terminal or D-Sub connector for reliable connection to field wiring.

- Software Control: Programmed and controlled using National Instruments software frameworks, primarily LabVIEW, LabWindows/CVI, or the NI-DAQmx driver software, which provides a unified API for configuration, reading, and writing.

- Counter/Timer: May include dedicated digital counter/timer channels for applications like frequency measurement or pulse generation.

Advantages and Key Features

- Superior Isolation and Protection: The individual channel isolation on the NI PXI-6527 is its standout feature, offering unmatched protection in noisy industrial settings where ground potential differences and voltage spikes are common. This ensures system stability and longevity.

- High-Density Industrial Interface: It consolidates multiple, fully isolated industrial I/O channels into a single PXI slot, providing a compact and powerful solution compared to using multiple lower-density or non-isolated modules.

- Integration with the NI Ecosystem: The module works seamlessly with the PXI platform’s timing and synchronization features (like PXI trigger buses) and is supported by the mature, well-documented NI-DAQmx driver software, drastically reducing development time.

- Flexible Software Definition: Unlike fixed-function PLC I/O, the PXI-6527 is a software-defined instrument. Its behavior (direction, timing, triggering) is completely determined by the user’s application in LabVIEW or other environments, offering extreme flexibility.

- High-Speed Performance: Leveraging the PXI bus, it can achieve much faster scan rates and more deterministic response times for digital I/O tasks than typical industrial bus-based I/O modules, which is crucial for high-speed test sequencing.

Application Case Studies in Various Fields

- Automated Test Equipment (ATE): Used in a “rack-and-stack” tester for automotive ECUs, where the NI PXI-6527 reads switch positions and controls relay matrices to route signals, with isolation ensuring test integrity.

- Manufacturing Functional Test: Integrated into a final test station for industrial appliances, where it simulates button presses (outputs) and reads LED/display status (inputs) as part of a fully automated test sequence.

- Real-Time Control & HIL Simulation: Employed in a Hardware-in-the-Loop (HIL) simulator for aerospace, where the module’s isolated outputs simulate discrete sensor signals (like proximity switches) to an aircraft control unit under test, and its inputs read the unit’s command responses.

- Industrial Prototyping & Research: Used in a university lab to control a custom-built manufacturing cell, where researchers use LabVIEW to program complex logic on the PXI-6527 to coordinate pneumatic cylinders and sensors.

Comparison with Competing Products

Compared to traditional PLC digital I/O modules or simpler USB/PCI data acquisition cards, the NI PXI-6527 occupies a specialized niche:

- Isolation and Voltage Level: It is specifically designed for industrial voltage levels (up to 60V) with per-channel isolation. Standard PLC modules are industrial but may share commons; simple DAQ cards are low-voltage (<10V) and rarely offer robust isolation.

- Platform Philosophy: The PXI-6527 is part of a measurement and test-centric platform (PXI) optimized for speed, synchronization, and software flexibility. PLC I/O is part of a control-centric platform optimized for ruggedness, deterministic scan cycles, and ladder logic programming.

- Development Model: It requires programming in languages like LabVIEW or C/C++ using NI-DAQmx, appealing to engineers and scientists. PLC I/O is configured and programmed within IEC 61131-3 environments (ladder logic, structured text), appealing to control technicians.

Selection Advice and Important Notes

- Verify Channel Configuration and Ratings: Confirm the exact number of input/output channels and their voltage/current specifications for the NI PXI-6527. Ensure they match your sensor and load requirements. Do not exceed the maximum ratings.

- Plan for Proper Wiring and Isolation: Understand the isolation scheme. Since channels are isolated, you must provide a voltage source and return for each input channel and for each output load. A common mistake is incorrectly wiring the return paths.

- Ensure Software and Driver Compatibility: You must use NI-DAQmx driver software and a compatible development environment (LabVIEW). Check the module’s support status for your operating system and software versions.

- Consider Heat Dissipation: High-density switching of inductive loads can generate heat. Ensure adequate airflow in the PXI chassis, especially if multiple PXI-6527 modules or other power-dissipating cards are used.

- Use Protective Circuitry for Inductive Loads: When driving solenoids or relays, always use flyback diodes or other suppression circuits across the inductive load to protect the PXI-6527‘s output transistors from voltage spikes.

ASMC2177-IX1006

467NHP811DP PLC

SC904-001-01

PP845-3BSE042235R1 PLC

469-P1-HI-A20-E-H

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922