Description

Product Overview and Introduction

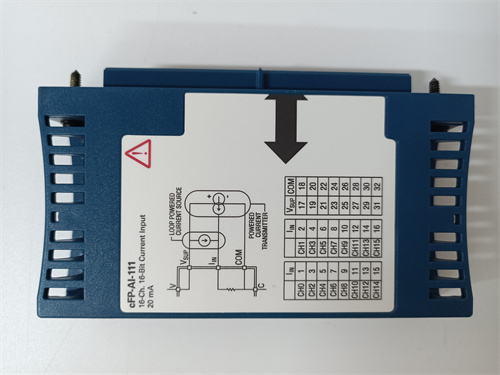

The NI CFP-AI-111 is a high-density, 16-channel analog input module designed for the National Instruments Compact FieldPoint (CFP) programmable automation controller (PAC) platform. This module serves as a critical interface for connecting a wide array of analog sensors—such as thermocouples, RTDs, voltage, and current transmitters—to a robust, distributed control and data acquisition system. Engineered for industrial environments, the NI CFP-AI-111 provides precise measurement capabilities, enabling monitoring and control of physical process variables like temperature, pressure, and flow. Its integration into the FieldPoint architecture makes it an ideal solution for applications requiring reliable, distributed I/O with deterministic control.

Detailed Product Parameters and Specifications

The performance of the CFP-AI-111 is defined by its precise electrical and functional specifications:

- Channel Count: 16 single-ended analog input channels, providing high-density signal connectivity in a compact form factor.

- Input Signal Types: Configurable per channel for a variety of signals:

- Voltage: Typically ranges such as ±10 V, 0-10 V.

- Current: 0-20 mA or 4-20 mA (using an external precision resistor).

- Thermocouple: Supports multiple standard types (e.g., J, K, T, E, N, B, R, S).

- RTD: Supports 2-, 3-, or 4-wire platinum RTDs (Pt100, Pt1000).

- Resolution: High-resolution analog-to-digital conversion, typically 16 bits, ensuring fine measurement granularity.

- Sampling Rate: Specifies the aggregate scanning rate for all channels, suitable for process monitoring applications.

- Input Isolation: Channels are typically isolated in banks (e.g., 4-channel banks) to prevent ground loops and protect the system from voltage transients.

- Accuracy: Defines the overall measurement uncertainty, combining gain, offset, and noise errors, which is particularly critical for temperature measurements.

- Connector: Utilizes a removable screw-terminal or spring-clamp connector block for secure and flexible field wiring.

- Operating Temperature: Rated for industrial environments, typically from -40 °C to 70 °C.

Key Advantages and Distinctive Features

The NI CFP-AI-111 module delivers significant benefits for distributed measurement and control:

- High Channel Density and Flexibility: Sixteen independently configurable channels in a single module save space in control cabinets and reduce system cost per point, accommodating diverse sensor types on one unit.

- Integrated Signal Conditioning: Built-in conditioning for thermocouples (cold junction compensation) and RTDs eliminates the need for external transmitters or conditioners, simplifying design and improving accuracy.

- Robust Industrial Design: As part of the Compact FieldPoint family, it is built to withstand shock, vibration, and wide temperature ranges, ensuring reliability in harsh factory or outdoor environments.

- Seamless Software Integration: Fully programmable and configurable with NI’s industry-standard LabVIEW and LabVIEW Real-Time modules, as well as support for other IEC 61131-3 languages via the NI FieldPoint controller, streamlining development.

- Deterministic Network Performance: When used with a FieldPoint network module or controller, it supports deterministic, shared variable communication over Ethernet for reliable, real-time control.

- Scalable System Architecture: The module’s design allows for easy expansion within the CFP rack, making the NI CFP-AI-111 a cornerstone for building scalable, distributed I/O systems.

Application Scenarios and Case Studies

This analog input module is deployed in a wide range of industrial monitoring and control applications:

- Industrial Machine Monitoring: Connecting multiple temperature sensors (thermocouples) and pressure transducers (4-20 mA) on a plastic injection molding machine or die-casting machine for process optimization.

- Energy Management Systems: Monitoring temperatures in transformer banks, bus bars, and switchgear cabinets in electrical substations using RTDs and thermocouples.

- Environmental Test Chambers: Acquiring precise temperature data from multiple zones within a chamber using a mix of RTD and thermocouple sensors to validate product performance.

- Water & Wastewater Treatment: Measuring pH, dissolved oxygen, tank levels, and flow rates via 4-20 mA signals from various analyzers and transmitters across a treatment plant.

A common case study involves a distributed temperature monitoring system for a food processing facility. The NI CFP-AI-111 modules, installed near cook tanks and freezers, directly connect dozens of RTD sensors. Data is acquired deterministically by a central FieldPoint controller, which runs a PID control algorithm to maintain precise temperatures, ensuring product quality and safety.

Comparison with Competing Products

Compared to similar high-density analog input modules from competitors like Emerson (DeltaV CHARMs), Siemens (ET 200SP AI modules), or Beckhoff (EL series terminals), the NI CFP-AI-111 occupies a distinct position:

- Software-Centric Flexibility: Its greatest strength is deep integration with NI’s graphical system design software (LabVIEW), offering unparalleled flexibility for complex custom measurement, control, and data logging applications compared to more traditional PLC-oriented modules.

- Built-in Sensor Support: The native, per-channel configurability for direct thermocouple and RTD connection without additional hardware is a significant advantage over many PLC I/O cards that require separate signal conditioners.

- Deterministic Distributed I/O: The CFP platform’s real-time Ethernet capabilities provide robust performance for distributed control, competing well with other fieldbus-based systems.

Competitors may offer advantages in tighter integration with their specific DCS or PLC ecosystems (e.g., TIA Portal for Siemens), lower cost per channel for simple voltage/current inputs, or different form factors. The choice heavily depends on whether the application leans toward high-flexibility data acquisition or tight integration into a conventional PLC/DCS control logic environment.

Selection Guidelines and Important Considerations

Proper selection and implementation of the NI CFP-AI-111 require careful planning:

- Verify System Compatibility: Ensure you have a compatible Compact FieldPoint backplane (e.g., CFP-180x, CFP-22xx) and a suitable network interface or controller (e.g., cFP-180x, cFP-22xx) to host and communicate with the module.

- Match Sensor Types Precisely: Confirm that the specific thermocouple type (J, K, etc.) or RTD wiring (2/3/4 wire) you intend to use is fully supported by the CFP-AI-111‘s firmware and configuration software.

- Consider Channel Utilization and Scanning: Be aware of the module’s aggregate scan rate. While suitable for process monitoring, it may not be appropriate for very high-speed, simultaneous sampling requirements.

- Plan for Configuration Software: You will need NI’s configuration software (LabVIEW, LabVIEW Real-Time Module, and potentially the FieldPoint Explorer utility) to configure, deploy, and program the system. Factor this into the total project cost.

- Wiring and Installation: Use high-quality, properly shielded cable for analog signals, especially for thermocouples and low-level voltages. Follow guidelines for grounding and isolation to maximize noise immunity. Always reference the installation manual for the NI CFP-AI-111, accessible via the product link, for specific wiring diagrams.

- Environmental Ratings: Confirm the operating temperature and humidity ranges are suitable for the installation location, especially for outdoor or unconditioned enclosures.

(SS) 1C31189G01/1C31192G01 SS EMERSON

(VP) 1C31194G01/1C31197G0c VP EMERSON

00-154-293

00-126-379 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922