Description

Product Description

The MTL 2213 is a precision two-wire signal conditioner and isolator, designed to convert a voltage input signal (typically 1-5V or 0-10V) into a standard two-wire 4-20mA current loop output. This device is a fundamental component in process instrumentation loops, serving as a critical interface between sensitive controller I/O cards and field-mounted transmitters or sensors. The primary function of the MTL 2213 is to provide galvanic isolation, noise filtering, and signal conversion, ensuring that the measurement signal from a field device is transmitted accurately and reliably to the control system, even in the presence of ground potential differences and electrical interference. By implementing the MTL 2213, engineers protect expensive control system inputs from damage due to ground loops or transients and improve the overall integrity of the measurement signal. Its two-wire, loop-powered design makes it simple to install and integrate into existing 4-20mA current loops.

Technical Parameters and Features

- Device Type: Two-wire, loop-powered voltage-to-current converter/isolator.

- Input Signal: Accepts a voltage input signal. Common standard ranges include:

- 1 to 5 VDC

- 0 to 10 VDC

- Other spans are configurable.

- Output Signal: Provides an isolated, proportional 4 to 20 mA two-wire current output.

- Power Supply: Loop-powered. It derives its operating power directly from the 4-20mA output loop, requiring no separate power supply. It imposes a low voltage drop (typically <5V) on the loop.

- Isolation: Provides high galvanic isolation (typically 1500V rms) between the input circuit and the output current loop. This breaks ground loops and protects equipment.

- Accuracy: High accuracy, typically ±0.1% of span or better.

- Linearity: Excellent linearity over the specified temperature range.

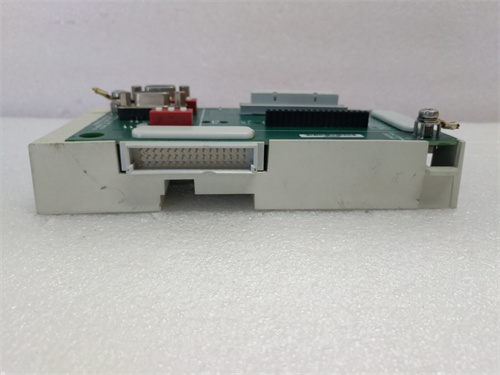

- Housing: Compact, rugged metal or high-grade plastic housing designed for DIN-rail mounting (35mm).

- Connections: Screw terminal blocks for easy wiring of input, output, and optional test connections.

- Indicators: May include an LED to indicate power/loop operation.

- Safety Certifications: Often certified for use in hazardous areas as an associated apparatus (e.g., ATEX, IECEx) when installed with appropriate intrinsic safety (IS) barriers.

Advantages and Key Features

- Simplified Installation and Wiring: The two-wire, loop-powered design of the MTL 2213 eliminates the need for a separate power supply, reducing wiring complexity, cost, and potential failure points in the installation.

- Superior Signal Integrity and Protection: Its high level of isolation prevents ground loops from causing measurement errors and protects control system inputs from voltage surges and transients originating in the field, a common problem in industrial plants.

- High Accuracy and Stability: MTL’s design ensures precise signal conversion with minimal drift over time and temperature, providing reliable and repeatable measurement data for process control and monitoring.

- Robust Industrial Design: Built to withstand the electrical noise, vibration, and temperature variations found in industrial control panels and field environments.

- Interoperability: Converts common voltage signals from various sensors (e.g., pressure transducers, load cells, variable-speed drive outputs) into the universal 4-20mA language of process control, enhancing system compatibility.

Application Case Studies in Various Fields

- Water Treatment Plant: A flow meter with a 0-10V output is connected to an MTL 2213 located in a remote junction box. The isolator converts the signal to 4-20mA for transmission over several hundred meters to the PLC in the main control room, preventing signal degradation and ground loop issues.

- Packaging Machine: A load cell on a filling machine produces a 1-5V signal. The MTL 2213 conditions this signal, isolates it from the noisy electrical environment of motors and drives, and provides a clean 4-20mA signal to the weight controller.

- HVAC Building Management: Converts a 0-10V signal from a variable frequency drive (VFD) indicating fan speed into a 4-20mA signal for the building’s legacy energy management system (EMS).

- Test Bench Data Acquisition: Used in a laboratory setup to interface a data logger or PLC with 4-20mA analog input cards to various sensors that only provide voltage outputs, ensuring accurate and isolated measurements.

Comparison with Competing Products

Compared to using a controller’s built-in voltage input card or a non-isolated converter, the MTL 2213 provides dedicated signal conditioning:

- Isolation vs. Direct Connection: Connecting a voltage signal directly to a PLC input card shares a common ground, creating a path for ground loop currents. The MTL 2213 provides galvanic isolation, which solves this problem completely, unlike a simple non-isolated converter or direct wiring.

- Dedicated Conditioning vs. General Purpose: While some PLCs have universal analog cards, they may not offer the same level of noise filtering, high-density isolation, or hazardous area suitability as a dedicated, purpose-built isolator like the 2213.

- Loop-Powered Convenience: Many competing signal conditioners require a separate 24V DC supply. The loop-powered operation of the MTL 2213 is a significant advantage in retrofit or space-constrained applications where adding a power supply is impractical.

Selection Advice and Important Notes

- Verify Input and Output Ranges: Ensure the MTL 2213 model you select is configured for the exact voltage input range (e.g., 1-5V, 0-10V) you require. Some models are field-configurable, while others are factory-set.

- Check Loop Voltage Compliance: Ensure the DC power supply for the 4-20mA loop can provide sufficient voltage to drive the MTL 2213‘s drop (e.g., 5V) plus the drop of any other loop devices and the input burden of the receiving card. The total loop resistance must be within the compliance range of the supply.

- Implement Proper Wiring Practices: Use shielded, twisted-pair cable for both the input voltage signal and the output current loop. Connect the cable shield at one end only (typically at the isolator or control system end) to prevent ground loops.

- Consider the Operating Environment: For installations in harsh or hazardous areas, confirm that the specific MTL 2213 variant has the necessary environmental ratings and safety certifications (e.g., IP rating, ATEX).

- Calibration and Testing: Periodically verify the calibration of the signal loop. The MTL 2213 itself is very stable, but the overall loop accuracy depends on the sensor, isolator, and receiving card.

NOVELLUS-03-034716-00 plc

IC754VSI06STD PLC

2711PC-T10C4D8

KJ3204X1-BA1 PLC

1FT6064-1AF71-4EG1

1785-BEM PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922