Description

Product Description

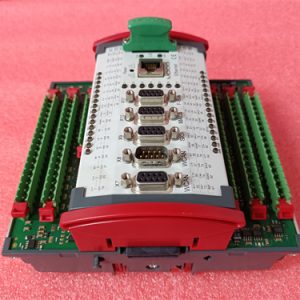

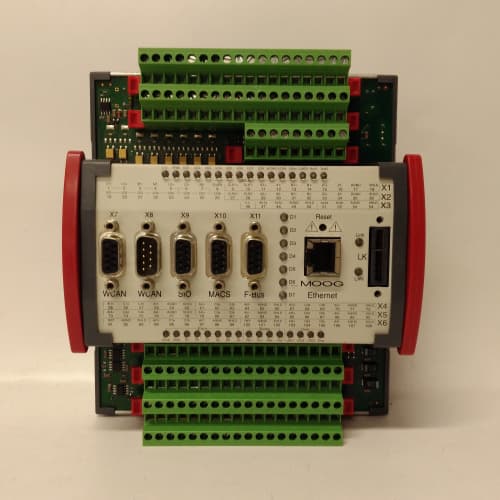

MOOG D136-004-001 is a high-performance servo valve controller designed by MOOG, a leader in motion control technology, specifically engineered for precise regulation of hydraulic/pneumatic servo systems in industrial automation and aerospace applications. Link to the product: [Link to MOOG D136-004-001]. As a core component of MOOG’s motion control product lineup, MOOG D136-004-001 integrates advanced closed-loop control algorithms and high-speed signal processing capabilities, enabling micron-level positioning accuracy and dynamic response—critical for applications requiring strict motion control. Compatible with MOOG’s full range of servo valves and third-party hydraulic actuators, MOOG D136-004-001 delivers reliable performance even in high-vibration, high-pressure industrial environments. D136-004-001 stands out for its flexible configuration, robust build quality, and seamless system integration, making it a preferred choice for precision manufacturing, aerospace testing, and heavy industrial machinery. Detailed specifications and purchasing information: [Link to MOOG D136-004-001].

Technical Parameters

- Brand: MOOG

- Model: D136-004-001

- Device Type: Precision Servo Valve Controller (Industrial/Aerospace Grade)

- Control Type: Closed-loop position/velocity/force control

- Input Signals: Analog (4–20 mA, ±10 V DC), Digital (PWM, Encoder A/B/Z), CANopen command signals

- Output Signals: Current output (0–500 mA) for servo valve drive, PWM output (up to 20 kHz)

- Positioning Accuracy: ±0.001 mm (with high-resolution encoder feedback)

- Response Bandwidth: Up to 500 Hz

- Maximum Output Current: 500 mA (continuous), 1 A (peak, 10 ms)

- Power Supply: 24 V DC (±15%), 110/220 V AC (optional dual-voltage module)

- Power Consumption: ≤ 15 W (at 24 V DC, no load)

- Operating Temperature Range: -40 °C to +85 °C

- Protection Rating: IP65 (for industrial use), IP67 (optional for harsh environments)

- Communication Protocols: CANopen, EtherCAT, Modbus TCP, PROFINET IO

- Compatible Components: MOOG G761/G765 servo valves, hydraulic/pneumatic actuators, incremental/absolute encoders

- Dimensions (W × H × D): 125 mm × 160 mm × 85 mm

- Certifications: ISO 9001, CE, UL 508C, RTCA DO-160 (aerospace), IEC 61000-4 (EMC)

- Warranty Period: 3 years

Advantages and Features

- Ultra-Precision Motion Control: MOOG D136-004-001 achieves ±0.001 mm positioning accuracy and a 500 Hz response bandwidth, enabling precise regulation of servo valves for high-speed, high-precision motion tasks such as CNC machining and aerospace component testing.

- Multi-Mode Control Capability: Supports position, velocity, and force control modes, with programmable parameters to adapt to diverse application requirements—from hydraulic press force regulation to robotic arm positioning.

- Robust Environmental Resilience: IP65 protection (IP67 optional) and a wide operating temperature range (-40 °C to +85 °C) ensure MOOG D136-004-001 performs reliably in harsh conditions, including heavy machinery, outdoor test rigs, and industrial manufacturing floors.

- High-Speed Communication & Integration: Equipped with EtherCAT and PROFINET IO protocols, offering low-latency data transmission (≤1 ms) for real-time motion synchronization; compatible with MOOG servo valves and third-party actuators/encoders.

- Advanced Diagnostics & Protection: Built-in overcurrent, overvoltage, and overtemperature protection, plus real-time monitoring of valve status, encoder feedback, and system errors—diagnostic data is accessible via software or communication protocols for quick troubleshooting.

- User-Friendly Configuration: Compatible with MOOG Motion Studio software for intuitive parameter tuning, control loop optimization, and motion profile programming; no specialized expertise required for basic setup.

Application Fields and Use Cases

- Aerospace & Defense (Component Testing): MOOG D136-004-001 controls servo valves in aircraft landing gear test rigs, simulating extreme load conditions with precise force and position regulation to validate component durability.

- Precision Manufacturing (CNC Machining Centers): In high-precision milling machines, the controller regulates hydraulic servo valves for spindle positioning and tool feed, ensuring micron-level machining accuracy for aerospace and medical components.

- Heavy Industry (Hydraulic Presses): D136-004-001 manages force control in hydraulic stamping presses, maintaining consistent pressure during metal forming processes to improve product quality and reduce material waste.

- Robotics (Industrial Robots): For large-load robotic arms in automotive assembly lines, the controller synchronizes servo valve operation with encoder feedback, enabling smooth, precise motion for welding, lifting, and component assembly.

Comparison with Competitors

- vs. Bosch Rexroth VT-HACD-1-1X/V0/T5: MOOG D136-004-001 offers higher positioning accuracy (±0.001 mm vs. Rexroth’s ±0.01 mm) and a wider response bandwidth (500 Hz vs. 300 Hz), making it better suited for ultra-precision applications.

- vs. Parker Hannifin D1VW Series Controllers: D136-004-001 supports more communication protocols (EtherCAT/PROFINET vs. Parker’s CANopen-only) and multi-mode control (position/velocity/force vs. position-only), enhancing flexibility.

- vs. Yaskawa Sigma-7 Servo Controllers: MOOG’s offering excels in hydraulic/pneumatic system integration (vs. Yaskawa’s focus on electric servos) and operates in harsher temperatures (-40 °C to +85 °C vs. Yaskawa’s -10 °C to +60 °C), ideal for heavy industrial use.

Selection Suggestions and Precautions

- Match Servo Valve Compatibility: Ensure MOOG D136-004-001 is compatible with your servo valve (e.g., MOOG G761/G765) or third-party models—verify output current (500 mA continuous) meets valve drive requirements.

- Define Control Requirements: Select the appropriate control mode (position/velocity/force) based on your application; for high-speed tasks, confirm the 500 Hz bandwidth aligns with motion dynamics.

- Power Supply Considerations: The standard 24 V DC model suits most industrial setups; opt for the dual-voltage (110/220 V AC) version if AC power is available, and ensure the supply can handle peak current (1 A).

- Installation Best Practices: Mount the controller in a dust-free, well-ventilated area; use shielded cables for encoder and signal connections to minimize electromagnetic interference (EMI) and maintain precision.

- Regular Calibration & Maintenance: Calibrate the controller annually using MOOG Motion Studio to preserve positioning accuracy; inspect wiring and connectors for wear, especially in high-vibration environments, to prevent signal loss.

- D136-004-001

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922