Description

Product Name

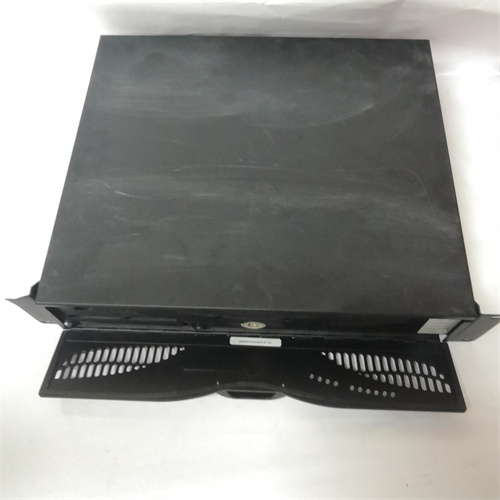

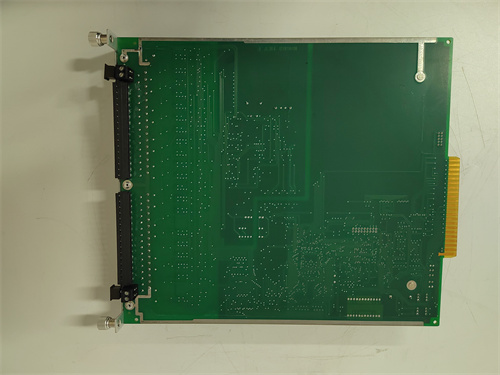

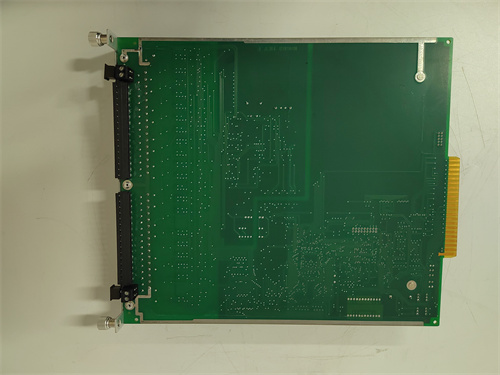

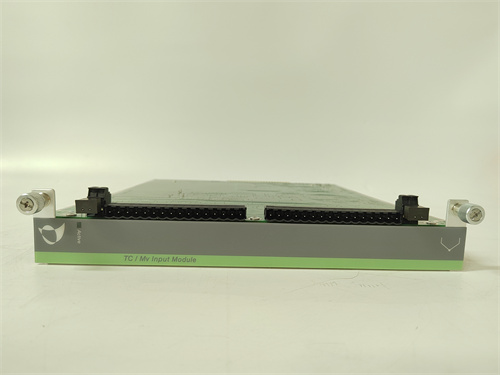

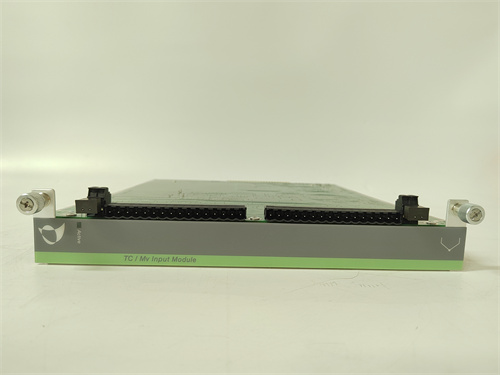

METSO IOP304 and IOP302

Product Description

The METSO IOP304 and IOP302 are advanced programmable logic controllers (PLCs) designed to optimize automation processes across various industrial sectors. Equipped with cutting-edge features and a robust architecture, IOP304 and IOP302 ensure seamless operations, efficient communication, and enhanced data handling capabilities. These models are pivotal for manufacturing systems, providing reliability and flexibility in machine control, data processing, and system monitoring.

Product Parameters

- Model: METSO IOP304

- Power Supply: 24 VDC

- Input/Output Capacity: Up to 512 I/O

- Communication Protocols: Ethernet/IP, Modbus TCP

- Memory: 2 MB RAM

- Operating Temperature: -20°C to 60°C

- Model: METSO IOP302

- Power Supply: 24 VDC

- Input/Output Capacity: Up to 256 I/O

- Communication Protocols: Profibus, Modbus RTU

- Memory: 1 MB RAM

- Operating Temperature: -20°C to 60°C

Advantages and Features

The METSO IOP304 and IOP302 offer several advantages that make them stand out in the realm of automation:

- Scalability: Both models support extensive I/O expansion, allowing for future growth and customization based on operational needs.

- User-Friendly Interface: Designed with intuitive programming software that simplifies setup and operational monitoring.

- Versatile Communication: Equipped with multiple communication protocols, these PLCs can easily integrate into diverse existing systems.

- Robust Build Quality: Built to withstand harsh industrial environments, ensuring longevity and reliability.

- Efficient Processing: High-speed processing capabilities to handle complex automation tasks effectively.

Application Fields

The METSO IOP304 and IOP302 are widely used in various industries, including:

- Manufacturing: For controlling assembly lines and robotic systems.

- Water Treatment: Automated control systems for pumps, valves, and monitoring sensors.

- Energy: Integration in power distribution systems and renewable energy applications.

- Food and Beverage: Automating processing and packaging lines to enhance productivity.

Application Cases

In a manufacturing setting, the METSO IOP304 has been effectively deployed to automate a multi-line assembly system. With its extensive I/O capabilities, it manages numerous machines simultaneously, increasing overall production efficiency by up to 30%. Meanwhile, the IOP302 has been utilized in a beverage processing plant to precisely control mixers and bottling lines, enhancing quality control and reducing waste.

Competitor Comparison

When compared to competitor models, the METSO IOP304 and IOP302 offer superior performance in terms of:

- Communication Flexibility: Unlike many rivals, these models support a broader range of communication protocols, essential for modern integrated systems.

- Memory Capacity: With higher RAM specifications, they allow for more complex programming and data handling without compromise.

- User Support: METSO provides extensive technical documentation and dedicated support, ensuring users can maximize the PLC’s potential.

Selection Suggestions

When choosing between METSO IOP304 and IOP302, consider the following:

- IOP304 is ideal for larger applications needing extensive I/O and processing capacity.

- IOP302 is suitable for smaller systems where efficiency and cost-effective solutions are prioritized.

Precautions

- Ensure compatibility with existing systems and requirements before installation.

- Consider environmental factors such as temperature and humidity that may affect performance.

- Regular maintenance and updates are recommended to sustain optimal functionality.

We are your trusted partner in automation solutions, offering sales and technical support for METSO IOP304 and IOP302 along with other automation spare parts. We provide special discount prices. Please contact us, and we will be dedicated to serving you.

METSO+IOP304 IOP302

FOXBORO FCP280 RH924YA

ABB PM825

GE DS200DCFBG1BNC

BENTLY 3500/22M

GE VMIVME-7452

GE VMIVME-7452

ABB “SPNPM22 ”

TOSHIBA USIO21

A-B 1756-L63

GE DS200DCFBG1BLC

YASKAWA JASP-WRCA01B

BAUMULLER BUS21L-7,5/15-31-224

NI SCXI-1104C

EATON XV-440-10TVB-1-10

BENTLY 1900/65A-01-01-03-00-00

Kollmorgen CB06551

SIEMENS 6DD1607-0CA1

Eaton XV-440-10TVB-1-20

Yaskawa JZNC-XPP02B

KUKA 00-168-334(配10米的电缆)

TRICONEX 3511

SIEMENS 6DD1661-0AD1

FOXBORO FCP270

TRICONEX 3301

PROSOFT 5302-MBP-MCM4

GE DS200DCFBG1BLC

YOKOGAWA CP451-10

PROSOFT PTQ-PDPMV1

TRICONEX 3704E

GE IC695CPE330

YOKOGAWA CP451-10

YOKOGAWA CP451-10

YOKOGAWA CP451-10

A-B 1336F-CWF75-AN-EN

YOKOGAWA CP451-10

ABB PM802F

GE DS200DCFBG1B

GE DS200DCFBG1BNC

GE PCIE-5565RC-100000

FANUC A06B-6320-H332

ABB 3HAC025338-006

B&R 5C5001.32

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922