Description

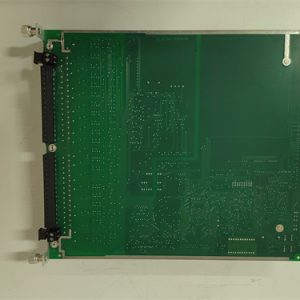

METSO PDP401 is a high-performance distributed processing unit (DPU) designed for industrial automation, ideal for oil and gas, chemical, power, and water treatment sectors requiring integrated data acquisition and process control. METSO PDP401 serves as a core bridge between field devices and upper-level DCS/PLC, handling real-time data collection, logic processing, and control signal output for valves, pumps, and actuators. METSO PDP401 supports multiple communication protocols and modular expansion, adapting to complex mixed-signal control scenarios with flexible configuration options. METSO PDP401 features rugged industrial design with IP65 protection, maintaining stability in harsh environments with dust, humidity, and electromagnetic interference. METSO PDP401 is fully compatible with IEC 61131-3 programming standards, enabling custom control logic for specific process requirements. METSO PDP401 integrates built-in safety functions and redundant backup capabilities, ensuring reliable operation of critical industrial processes.

Technical Parameters METSO PDP401

| Parameter Item | Parameter Value |

|---|---|

| Product Model | METSO PDP401 |

| Product Type | Distributed processing unit (DPU) |

| Core Function | Data acquisition, process control, monitoring & alarm |

| Input Voltage | 24V DC (industrial standard) |

| Output Voltage | 24V DC |

| Maximum Output Current | 10A |

| Rated Power | 240W |

| Operating Temperature Range | -20°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Protection Level | IP65 |

| Communication Protocols | Modbus, Profinet, Ethernet, RS-232, RS-485, Profibus DP |

| Programming Support | IEC 61131-3 (LD, ST, FBD) |

| Memory Configuration | Up to 1GB SDRAM, 2GB Flash memory |

| Dimensions | 22mm × 124mm × 126mm |

| Weight | 2.5kg |

| Mounting Type | 6U VMEbus module |

| Compatibility | METSO automation systems, mainstream DCS/PLC platforms |

| MTBF | ≥180,000 hours |

| Certifications | CE, UL |

| Protection Features | Overcurrent, anti-interference, redundant backup |

| Warranty Period | 1 year |

Advantages and Features METSO PDP401

- Integrated Data & Control: METSO PDP401 combines data acquisition, processing, and control in one unit, eliminating the need for separate modules and simplifying system architecture.

- Flexible Expandability: Modular design of METSO PDP401 supports customized channel and function expansion, adapting to diverse industrial process requirements.

- Multi-Protocol Compatibility: METSO PDP401 supports multiple mainstream communication protocols, enabling seamless integration with field devices and upper-level control systems.

- Rugged Reliability: IP65 protection and industrial-grade components ensure METSO PDP401 operates stably in harsh environments with dust, humidity, and electromagnetic interference.

- Customizable Logic: Compliance with IEC 61131-3 standards allows users to program custom control algorithms for METSO PDP401, meeting specific process needs.

- Safety & Redundancy: Built-in safety functions and redundant backup of METSO PDP401 minimize downtime risks for critical industrial processes.

Application Cases METSO PDP401

- Oil and Gas Pipeline Control: An oilfield enterprise deployed METSO PDP401 to monitor and control pipeline valves and pumps. Its multi-protocol support integrated flow sensors and pressure transmitters, reducing unplanned downtime by 28%.

- Chemical Plant Batch Process Control: A chemical manufacturer used METSO PDP401 to coordinate reactor temperature regulation and material feeding. Custom programming via IEC 61131-3 optimized reaction cycles, increasing product yield by 15%.

- Power Plant Auxiliary System Monitoring: A thermal power plant integrated METSO PDP401 to manage boiler feedwater and dust removal systems. Redundant backup ensured uninterrupted operation, improving system availability by 99.9%.

- Water Treatment Process Automation: A municipal wastewater plant utilized METSO PDP401 for water quality monitoring and treatment process control. Its anti-interference design maintained stable data transmission amid electrical noise, enhancing treatment efficiency by 22%.

Competitor Comparison

| Feature | METSO PDP401 | METSO IOP353 (I/O Interface Controller) | Siemens ET 200Pro |

|---|---|---|---|

| Core Function | Distributed processing + integrated control | I/O interface + basic logic control | Distributed I/O processing |

| Integration Level | All-in-one data acquisition & control | I/O-focused, limited processing | I/O expansion, dependent on upper system |

| Protocol Support | Multiple protocols (Modbus/Profinet/Profibus) | Basic mainstream protocols | Siemens-centric protocols |

| Protection Level | IP65 | IP65 | IP54 |

| Redundancy | Supported | Optional | Optional |

| Programming Flexibility | IEC 61131-3 compliant | Limited | Basic configuration |

| MTBF | 180,000+ hours | 170,000+ hours | 160,000+ hours |

| Price Range | Mid-High | Mid-Range | High |

Selection Suggestions

- Choose METSO PDP401 for complex process control scenarios (e.g., chemical batch production) to leverage its integrated data processing and custom programming capabilities.

- Prioritize METSO PDP401 for harsh environment applications like oil and gas fields, where its IP65 protection and anti-interference design ensure reliability.

- Select METSO PDP401 for critical systems requiring redundancy, as its backup functions minimize downtime risks in power and water treatment industries.

Precautions

- Ensure METSO PDP401’s input voltage is stable at 24V DC to avoid processing errors or module damage.

- Confirm communication protocol compatibility between METSO PDP401 and upper-level DCS/PLC before integration to ensure seamless data exchange.

- Follow IEC 61131-3 standards when programming METSO PDP401 to avoid logic conflicts affecting process control.

- Install METSO PDP401 in a well-ventilated area to prevent overheating, especially in high-temperature industrial environments.

- Regularly inspect the module’s connectors and wiring to maintain reliable signal transmission for METSO PDP401.

FOXBORO P0914TG FBM241

FOXBORO P0917GZ FBM240

FOXBORO P0700TU

FOXBORO P0700TT

FOXBORO P0700TJ

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922