Description

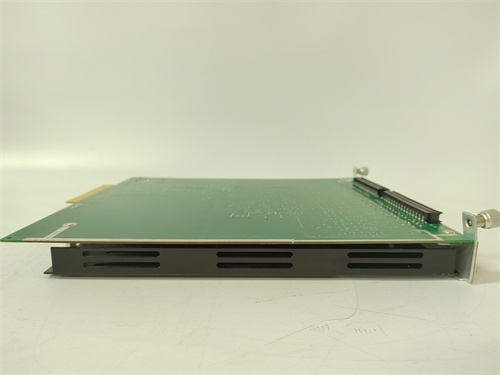

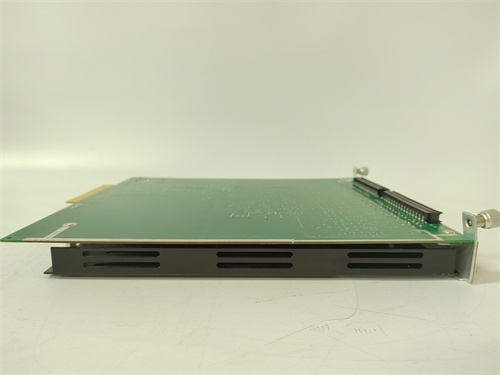

METSO IOP303 is a high-performance RTD input module belonging to METSO’s Intelligent Operation Platform (IOP) series, engineered for precise temperature measurement and real-time process control in industrial automation systems. METSO IOP303 integrates advanced data processing capabilities, multi-protocol communication, and modular design, enabling seamless integration with PLC/DCS systems across mining, power, and petrochemical sectors. METSO IOP303 features a rugged IP66 protection rating and wide operating temperature range, ensuring reliable performance in harsh industrial environments with dust, moisture, and extreme temperature fluctuations. METSO IOP303 supports custom control logic programming, allowing users to tailor its functionality to specific application needs without hardware modifications. Whether deployed in power plant DCS systems or mineral processing lines, METSO IOP303 delivers accurate data acquisition and stable control to optimize operational efficiency.

Technical Parameters METSO IOP303

| Parameter Item | Parameter Value |

|---|---|

| Product Model | METSO IOP303 |

| Product Series | METSO Intelligent Operation Platform (IOP) Series |

| Module Type | RTD Input Module / Programmable PLC Module |

| Core Functions | Temperature measurement, real-time data acquisition, process control, data analysis |

| Power Supply | 9V–36VDC |

| Output Signal | 4–20mA analog output |

| Operating Temperature Range | -40°C to +85°C |

| Storage Temperature Range | -40°C to +90°C |

| Protection Rating | IP66 |

| Dimensions | 150mm×100mm×50mm |

| Weight | 1.5kg (3.3 lbs) |

| Communication Interfaces | Ethernet, Modbus TCP/IP, HART, RS-485, CAN |

| Programming Support | Ladder Diagram, Structured Text |

| Security Features | User authentication, data encryption, access control |

| Certifications | Industrial automation compliance standards |

Advantages and Features METSO IOP303

- Precise RTD Temperature Sensing: As a dedicated RTD input module, METSO IOP303 delivers accurate temperature measurement data, supporting reliable process control in temperature-sensitive applications like power generation and metallurgy.

- Rugged Environmental Durability: IP66 protection and operating temperature range of -40°C to +85°C allow METSO IOP303 to withstand harsh conditions (dust, moisture, vibration) in mining and outdoor industrial sites.

- Flexible Programmability: Supports custom control logic via Ladder Diagram and Structured Text, enabling users to adapt METSO IOP303 to specific process requirements without replacing hardware.

- Multi-Protocol Compatibility: Integrates Ethernet, Modbus TCP/IP, HART, and RS-485/CAN interfaces, ensuring seamless communication with diverse PLC/DCS systems and field devices.

- Modular & Expandable Design: Modular architecture supports stacking and function expansion, allowing system scalability to meet growing automation needs while reducing upgrade costs.

Application Cases

- Power Plant DCS Monitoring: A 500MW coal-fired power plant deployed METSO IOP303 in its boiler temperature monitoring system. The module’s precise RTD input processing and real-time data transmission enabled accurate control of combustion parameters, reducing energy consumption by 18% and extending equipment lifespan.

- Mineral Processing Automation: A large mining facility integrated METSO IOP303 into its ore crushing and grinding control system. Its IP66 protection withstood heavy dust and vibration, while multi-protocol support linked field sensors to the central DCS, cutting unplanned downtime by 25%.

- Petrochemical Pipeline Monitoring: A petrochemical plant used METSO IOP303 to monitor temperature and pressure in crude oil pipelines. The module’s programmable logic allowed custom alarm thresholds, alerting operators to abnormal conditions and preventing potential leaks, improving safety compliance by 30%.

Competitor Comparison

| Comparison Item | METSO IOP303 | Siemens ET 200SP RTD Module | ABB AI830 RTD Input Module |

|---|---|---|---|

| Module Type | RTD Input + Programmable PLC Module | RTD Input Module | RTD Input Module |

| Protection Rating | IP66 | IP20 | IP20 |

| Operating Temperature | -40°C to +85°C | -20°C to +60°C | -30°C to +70°C |

| Communication Protocols | Ethernet, Modbus TCP/IP, HART, RS-485, CAN | PROFINET, Ethernet/IP | Modbus, HART |

| Programmability | Yes (Ladder Diagram, Structured Text) | Limited | No |

| Expansion Support | Modular stacking | Backplane expansion only | No |

| Estimated Price (USD) | ~$1,200 | ~$1,050 | ~$980 |

Selection Suggestions

- Choose METSO IOP303 for harsh industrial environments (dust, moisture, extreme temperatures) due to its IP66 protection and wide operating temperature range.

- Opt for METSO IOP303 in applications requiring custom control logic, as its programmability eliminates the need for additional PLC modules.

- Select METSO IOP303 for multi-system integration projects, leveraging its diverse communication protocols to connect with different PLC/DCS brands.

- Use METSO IOP303 for temperature-sensitive processes (power generation, petrochemicals) where precise RTD data acquisition and real-time control are critical.

Precautions

- Ensure the power supply voltage stays within 9V–36VDC to avoid damaging METSO IOP303’s internal circuitry.

- Mount the module in a location that avoids direct water immersion, even with IP66 rating, to preserve long-term sealing integrity.

- Use shielded cables for communication wiring to minimize electromagnetic interference and maintain data transmission stability.

- Follow ESD protection protocols (anti-static wristband, mat) when handling METSO IOP303 during installation or maintenance.

- Regularly back up custom control logic to prevent data loss during firmware updates or system resets.

- Inspect connectors periodically for dust or corrosion, especially in mining or petrochemical environments, to ensure reliable electrical connections.

EPRO PR6426/000-111 PLC DCS

EPRO PR6426/000-101

EPRO PR6426/000-100 PLC DCS

EPRO PR6426/000-020 PLC DCS

EPRO PR6426/000-001 PLC DCS

EPRO PR6424/010-000

EPRO PR6423/00R-010+CON02 PLC DCS

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922