Description

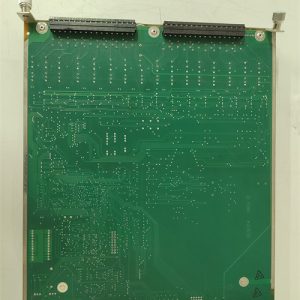

METSO IOP302 I/O Module

Product Description

The METSO IOP302 is a digital input/output (I/O) module designed for Metso’s (now part of Valmet) DNA distributed control and information system. This module serves as a versatile field interface, providing a configurable mix of digital inputs and outputs to connect a wide array of field devices like push buttons, limit switches, solenoid valves, and indicator lights directly to the control system. As a key component in the DNA system’s I/O hierarchy, the METSO IOP302 enables the reliable acquisition of discrete status signals and the execution of on/off control commands for process and machinery automation. Its robust industrial design ensures dependable performance in the challenging environments of process industries such as pulp, paper, and energy. For comprehensive technical documentation and configuration manuals, please visit the official product resource: METSO IOP302. The integration of the IOP302 module into a DNA I/O station expands the system’s capability to handle essential logic control and interlocking functions. The flexibility and reliability of the METSO IOP302 make it a fundamental building block for implementing discrete control strategies within the larger DNA automation architecture, ensuring seamless communication between field devices and the system’s controllers.

Product Parameters

- Product Model: METSO IOP302

- System Platform: Metso (Valmet) DNA Distributed Control System.

- Module Type: Digital Input/Output (Mixed I/O) Module.

- Channel Configuration: Typically provides a combination of digital inputs (DIs) and digital outputs (DOs) in one unit, such as 8 inputs and 8 outputs.

- Input Specifications:

- Type: 24V DC, electrically isolated, configurable for sinking or sourcing operation.

- Isolation: Group or channel-to-channel isolation.

- Output Specifications:

- Type: Typically transistor outputs for 24V DC loads.

- Current Rating: Defined per point and total module current.

- Communication: Connects to the DNA system via a fieldbus connection (typically Profibus DP) through a DNA Fieldbus Interface Module (FIM), or directly to a DNA Controller Unit’s I/O bus.

- Diagnostics: Features LED status indicators for each channel or group, providing clear visual feedback for power, communication, and I/O state.

- Configuration: Module parameters and I/O mapping are configured using the DNA engineering tools.

- Power Supply: Receives power from the DNA I/O station’s internal power bus or an external 24V DC source, as per design.

- Mounting: Designed for installation on a DIN rail within a DNA I/O station or enclosure.

Advantages and Features

- Space-Efficient and Flexible Design: Combining inputs and outputs in a single module optimizes space in control cabinets and offers application flexibility, ideal for controlling small machines or skids with a balanced number of sensors and actuators.

- High Noise Immunity: Engineered with industrial-grade isolation and filtering to ensure reliable operation in electrically noisy environments typical of mills and plants.

- Clear Visual Diagnostics: Per-channel or group LEDs allow for immediate on-site troubleshooting, reducing downtime by quickly identifying faulty field devices or wiring issues.

- Robust Industrial Construction: Built to withstand vibration, wide temperature ranges, and humidity, ensuring long-term reliability in harsh industrial settings.

- Seamless DNA System Integration: As a native Metso/Valmet DNA component, the IOP302 is fully supported by the DNA engineering and operator station software, enabling easy configuration, monitoring, and maintenance within the unified system environment.

Application Cases in Various Fields

- Pulp and Paper Machine Section Control: Used on a paper machine’s drive control cabinet to read limit switches for broke conveyor positions and to control solenoid valves for lubrication or shower systems.

- Board Machine Automation: Controls the sequencing of vacuum pumps and felt guide actuators in a board machine, using inputs for pump status and outputs for actuator control.

- Power Plant Auxiliary Systems: Manages coal feed system components in a boiler house, monitoring bin level switches and controlling feed conveyor motor contactors.

- Chemical Recovery Island: Provides discrete I/O for valve sequencing and pump interlocks in the chemical recovery process of a pulp mill.

Comparison with Competing Products

The METSO IOP302 competes with mixed digital I/O modules from other process DCS vendors like ABB (S800), Siemens (ET 200M/SP), and Honeywell (Experion FIO). Its primary advantage is its guaranteed compatibility, optimized performance, and streamlined engineering workflow within the Metso/Valmet DNA ecosystem, which is dominant in the pulp, paper, and power industries. Compared to using separate input and output modules, the IOP302 offers cost and space savings. Against generic Profibus I/O blocks, it provides deeper integration with the DNA controller’s diagnostics and configuration tools, offering a more cohesive solution for plant-wide automation.

Selection Suggestions and Precautions

- DNA System Compatibility: Verify that the METSO IOP302 is compatible with your specific DNA system hardware, including the controller generation (e.g., DNA Controllers UC, UP, UN) and the fieldbus interface module (FIM) or I/O bus being used.

- I/O Mix and Load Verification: Confirm that the module’s mix of input and output channels meets your application’s requirements. For outputs, calculate the total current draw of all connected loads to ensure it does not exceed the module’s total output current rating.

- Correct Wiring and Sourcing/Sinking: Pay close attention to the wiring diagram. Ensure your field devices are wired correctly to match the module’s configured sourcing or sinking input circuitry and output type. Incorrect wiring is a common cause of module failure or non-operation.

- Fieldbus Address Configuration: If used on a Profibus DP network via an FIM, ensure the IOP302 module (or its parent unit) is assigned a unique Profibus node address that does not conflict with other devices on the same segment.

SPAJ142C

MDX61B0110-5A3-4-oT PLC

74-2460KRH10 PLC

0010-13445 PLC

HCMCO3MC-1A PLC

ABB-NTST01 PLC

SPBRC410

3HAC031851-001 PLC

2711-K5A1 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922