Description

Product Analysis Report

Product Description

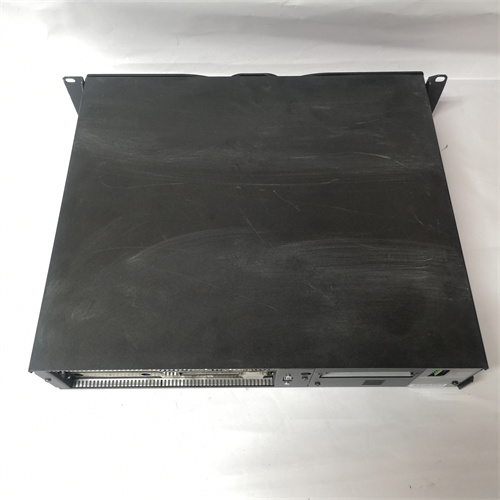

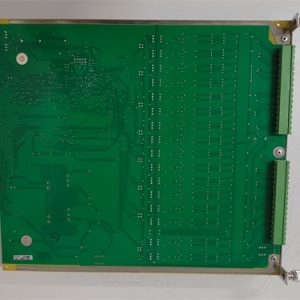

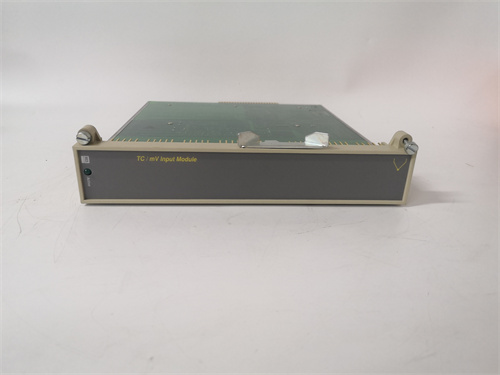

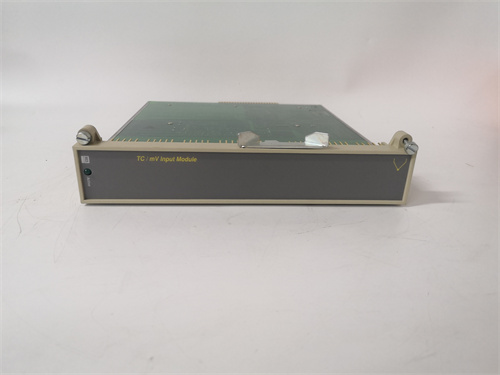

The METSO IOP114 is a specialized industrial automation module designed for precise control and monitoring applications within process automation systems. As a key component from Metso’s renowned instrumentation portfolio, the METSO IOP114 (product link: METSO IOP114) serves as a robust interface and processing unit. It is engineered to integrate seamlessly with larger control systems, facilitating reliable data acquisition and output control. The core functionality of the METSO IOP114 centers on providing a dependable hardware interface for various field signals, ensuring high integrity in industrial environments. Its design emphasizes durability and consistent performance, making the METSO IOP114 a trusted choice for engineers seeking a solid foundation for their control architecture.

Product Parameters

- Type: Digital/Analog I/O Module (Specific type, e.g., Isolated Input/Output, to be confirmed from datasheet)

- Compatibility: Designed for integration with Metso (now part of Valmet) automation systems and certain PLC/control platforms.

- Channels: Typically features a configurable number of input/output channels (exact count is model-specific).

- Signal Ranges: Supports standard industrial signal levels (e.g., 4-20mA analog, 24V DC digital).

- Isolation: High-grade channel-to-channel and system isolation for noise immunity and safety.

- Communication Protocol: Often interfaces via a proprietary or industry-standard fieldbus (details are system-dependent).

- Operating Temperature: Rated for standard industrial temperature ranges (e.g., -20°C to +70°C).

- Power Supply: Operates on standard DC voltages common in control panels.

- Certifications: Complies with relevant industrial EMC, safety, and environmental standards.

Advantages and Features

- High Reliability: Built with industrial-grade components for long-term, stable operation in demanding conditions.

- Excellent Noise Immunity: Strong isolation protects sensitive control systems from ground loops and electromagnetic interference.

- Seamless Integration: The METSO IOP114 is optimized for use within Metso/Valmet ecosystem, ensuring easy configuration and reliable communication.

- Compact and Robust Design: Saves panel space while withstanding vibration, temperature fluctuations, and electrical noise common in industrial settings.

- Maintainability: Designed for easy troubleshooting and replacement, minimizing system downtime.

Application Cases in Key Fields

- Pulp and Paper Industry: Used in distributed control systems (DCS) for controlling motors, valves, and sensors on paper machines, digesters, and chemical preparation areas.

- Minerals and Mining Processing: Employed in control panels for monitoring level, flow, and pressure transmitters, and controlling actuators in crushing, grinding, and flotation circuits.

- Energy and Utilities: Integrates into boiler control and turbine monitoring systems for reliable data gathering from critical process points.

- Chemical Processing: Provides isolated I/O handling for batch processes and continuous production lines where signal integrity is paramount.

Comparisons with Competing Products

Compared to generic or low-cost I/O modules from broader automation suppliers, the METSO IOP114 offers superior integration and performance within its native Metso/Valmet system environment. Its build quality and isolation specifications often exceed those of entry-level modules from competitors like generic PLC rack I/O cards. However, it may be less versatile as a standalone component in a multi-vendor PLC system compared to universal I/O modules from brands like Siemens (ET 200SP) or Allen-Bradley (Point I/O). Its primary advantage is its proven performance and support within the context of a larger Metso automation solution.

Selection Suggestions and Precautions

- System Compatibility Verification: Before selection, explicitly confirm that the METSO IOP114 is compatible with your existing or planned controller/backplane. Check the required firmware versions and communication modules.

- Exact Specification Check: Ensure the specific variant’s channel count, signal type (sinking/sourcing, analog/digital), and voltage ranges match your sensor and actuator requirements.

- Environmental Suitability: Verify that its temperature rating and protection class (IP) are adequate for the installation location (e.g., control cabinet vs. field enclosure).

- Obsolescence Considerations: As Metso’s automation business is now under Valmet, check the current availability and long-term support status for this specific module from Valmet’s spare parts channels.

- Professional Installation: Ensure installation follows EMC guidelines, with proper grounding and cable separation to achieve the module’s specified performance. Use trained personnel for configuration and commissioning.

3HNE06225-1/02 ABB DCS

ABB 3HNE05036-1

ABB 3HNA006149-001 DCS

3HNE05034-1 DCS

3HNE00413-1

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922