Description

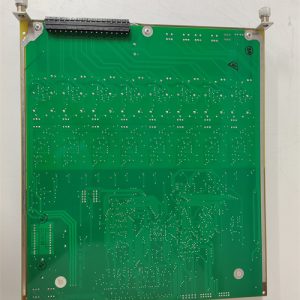

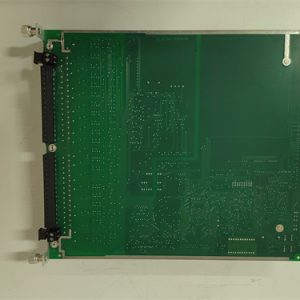

METSO D201463 is a high-reliability process control module tailored for mineral processing, metallurgy, and water treatment sectors, enabling precise regulation of filtration, separation, and slurry handling processes. METSO D201463 serves as a core control unit for automated systems like dual-media filters, coordinating valve actuation, flow regulation, and backwash cycles with minimal human intervention. METSO D201463 supports real-time data exchange with field sensors and upper-level DCS, ensuring process parameters such as flow rate and particle concentration are continuously monitored and adjusted. METSO D201463 integrates energy-saving control logic, aligning with Metso’s Planet Positive sustainability strategy to reduce operational power consumption. METSO D201463 features robust anti-interference design, maintaining stable performance in industrial environments with high electromagnetic interference and harsh operating conditions. METSO D201463 is fully compatible with Metso’s process automation ecosystem and mainstream third-party PLCs, facilitating seamless integration into existing production lines.

Technical Parameters METSO D201463

| Parameter Item | Parameter Value |

|---|---|

| Product Model | METSO D201463 |

| Product Type | Process control module (mineral processing & filtration focus) |

| Control Channels | 12 digital I/O, 6 analog I/O (configurable) |

| Supported Communication Protocols | Modbus RTU/TCP, Profinet, Ethernet/IP |

| Input Voltage | 24V DC (industrial standard) |

| Output Power | 100W (max) |

| Measurement Resolution | 16-bit (analog signals) |

| Control Accuracy | ±0.1% FS |

| Operating Temperature Range | -30°C to +85°C |

| Storage Temperature | -40°C to +100°C |

| Relative Humidity | 5% – 95% (non-condensing) |

| Protection Level | IP65 |

| Dimensions | 105mm × 125mm × 30mm |

| Weight | 400g |

| Mounting Type | 35mm DIN rail |

| Compatibility | Metso process automation systems, ABB 800xA, Siemens S7 series |

| MTBF | ≥160,000 hours |

| Certifications | CE, UL, IEC 61131-2 |

| Power Consumption | 15W (max) |

| Protection Features | Overcurrent, anti-surge, reverse polarity protection |

| Warranty Period | 1 year |

Advantages and Features METSO D201463

- Process-Specific Control: METSO D201463 is optimized for filtration and mineral processing, with preconfigured logic for dual-media filters and slurry handling systems.

- Energy Efficiency: Integrated Planet Positive-aligned control algorithms reduce METSO D201463’s operational power consumption, lowering long-term running costs.

- Rugged Stability: IP65 protection and wide temperature tolerance ensure METSO D201463 performs reliably in harsh mineral processing and metallurgy environments.

- Flexible Compatibility: METSO D201463 integrates seamlessly with Metso’s ecosystem and third-party PLCs, minimizing integration efforts for system upgrades.

- Precise Regulation: 16-bit resolution and ±0.1% FS accuracy enable METSO D201463 to maintain tight control over critical process parameters like flow rate and particle concentration.

- Automated Operation: Supports full-cycle automation of filtration systems, reducing manual intervention and improving process consistency.

Application Cases METSO D201463

- Mineral Processing Filtration Control: A large mining company deployed METSO D201463 to control dual-media filters for ore slurry purification. Its automated backwash logic reduced organic and particle contamination to ppm levels, improving concentrate quality by 22%.

- Metallurgy Electrolyte Filtration: A metallurgical plant used METSO D201463 to regulate electrolyte filtration systems. Energy-saving control reduced pumping power consumption by 18% compared to legacy modules, aligning with sustainability goals.

- Water Treatment Plant Filtration: A municipal water treatment facility integrated METSO D201463 to automate sand-water dual-media filters. Real-time flow and pressure monitoring cut filter maintenance downtime by 30%.

- Chemical Industry Solution Purification: A chemical enterprise utilized METSO D201463 to control crystallization feed solution filtration. Its high control accuracy reduced impurity levels, increasing product yield by 15%.

Competitor Comparison

| Feature | METSO D201463 | METSO IOP353 (I/O Interface Controller) | Siemens ET 200SP |

|---|---|---|---|

| Core Function | Process control (filtration/mineral processing) | I/O interface + basic logic control | Distributed I/O & control |

| Industry Optimization | Mineral processing/filtration-specific | General industrial use | General industrial use |

| Energy-Saving Design | Planet Positive-aligned | Standard power consumption | Basic energy management |

| Protection Level | IP65 | IP65 | IP20 |

| Control Accuracy | ±0.1% FS | ±0.1% FS | ±0.2% FS |

| Compatibility | Metso ecosystem + third-party | Multi-system integration | Siemens-centric |

| MTBF | 160,000+ hours | 170,000+ hours | 160,000+ hours |

| Price Range | Mid-High | Mid-Range | High |

Selection Suggestions

- Choose METSO D201463 for mineral processing and metallurgy filtration systems, leveraging its industry-specific control logic and energy-saving features.

- Prioritize METSO D201463 for harsh environment applications, as its IP65 protection outperforms cabinet-mounted alternatives in dusty or humid sites.

- Select METSO D201463 for sustainability-focused projects, thanks to its Planet Positive-aligned design that reduces operational energy consumption.

Precautions

- Ensure METSO D201463’s input voltage is stable at 24V DC to avoid control inaccuracies or module damage.

- Configure communication protocols correctly to ensure seamless data exchange between METSO D201463 and upper-level DCS/PLC.

- Regularly calibrate METSO D201463 to maintain ±0.1% FS accuracy, especially in long-term continuous filtration processes.

- Avoid installing METSO D201463 near high-voltage equipment or strong electromagnetic sources to prevent signal interference.

- Use shielded cables for sensor connections to METSO D201463, enhancing anti-interference performance in mineral processing environments.

FOXBORO P0400YE FBM04

FOXBORO PO400YD FBM03

FOXBORO P0400DA FBM01

FOXBORO P0961FR CP60

FOXBORO P0960JA CP40

FOXBORO P0971WV DNBT

FOXBORO P0970BC DNBI

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922