Description

Product Description

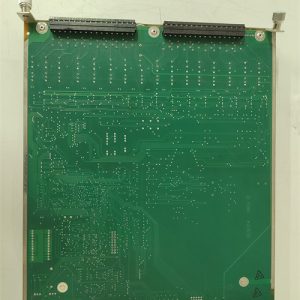

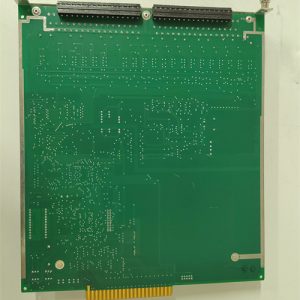

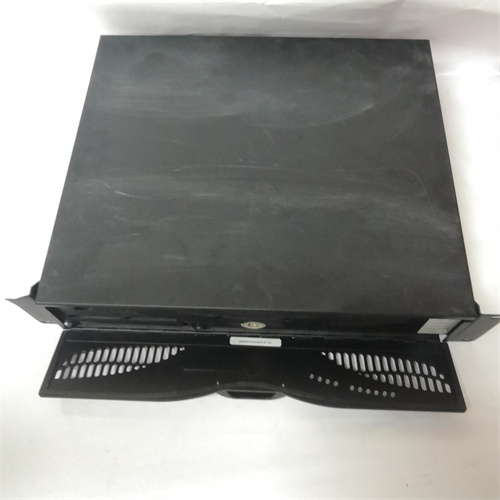

The METSO D100314 is an automation system component from Metso (now part of Valmet), a leader in process industry technology for pulp, paper, power, and minerals. This part number identifies a specific controller, I/O module, or critical accessory within Metso’s DNA (Distributed Network Architecture) or other legacy automation systems. The primary function of the METSO D100314 is to serve as a building block in a distributed control system (DCS), performing tasks such as executing control logic, interfacing with field devices, or managing communication between system nodes. These systems are engineered for the rigorous demands of continuous process industries, where reliability and precise control are paramount. Integrating the METSO D100314 into a control architecture ensures compliance with Metso’s validated system designs, which are optimized for complex processes like paper machine control, chemical recovery, or mineral processing. Its role is foundational to maintaining the high availability and performance expected in these capital-intensive plants.

Technical Parameters and Features

- Device Type: Automation System Component (Specific type to be verified—could be a CPU, Communication, or I/O module for Metso DNA/Neles/NDC systems).

- System Compatibility: Designed for integration into specific Metso/Valmet automation platforms. The “D” prefix often relates to the DNA (Distributed Network Architecture) system or a related product line.

- Primary Function (Likely Scenarios):

- Controller Module: Contains a processor and memory to execute application software for a control loop or sub-process.

- I/O Module: Provides analog or digital input/output channels for connecting field sensors (pressure, temperature, position) and actuators (valves, motors).

- Communication Module: Acts as a network interface or bus coupler for connecting subsystems or field networks.

- Communication Interface: Would utilize Metso’s proprietary or industry-standard networks (e.g., DNA bus, Modbus, Profibus) for integration within the larger control system.

- Configuration: Programmed and configured using Metso’s dedicated engineering tools (e.g., Metso DNA Engineering Tools). Logic is typically built using function block diagrams or other IEC 61131-3 languages.

- Environmental Rating: Built to industrial standards for installation in control cabinets within mill or plant environments, with resistance to temperature, humidity, and electrical noise.

- Form Factor: Typically a modular, rack-mounted card or a standalone unit designed for a specific chassis.

Advantages and Key Features

- Process-Optimized Design: Components like the METSO D100314 are designed with deep process knowledge, particularly for the pulp, paper, and energy sectors. Their algorithms and response characteristics are tuned for the specific dynamics of these industries.

- High System Integrity and Reliability: Metso’s automation systems are known for their robustness in 24/7 operation. The D100314 module is built to this standard, offering high mean time between failures (MTBF) to minimize unplanned downtime.

- Seamless Integration within the Metso Ecosystem: As a genuine Metso part, it guarantees full compatibility and optimal performance with other system components (controllers, I/O, HMIs), ensuring predictable behavior and simplifying engineering.

- Long-Term Lifecycle Support: For legacy systems, Metso (Valmet) typically provides extended lifecycle support, including spare parts like the D100314, which is crucial for maintaining existing plant infrastructure without a costly full system migration.

- Application-Specific Expertise: Using authentic modules ensures continued access to Valmet’s deep application expertise and support for the complex control strategies they were designed to execute.

Application Case Studies in Various Fields

- Paper Machine Wet End Control: A METSO D100314 controller module could manage the consistency and flow control loops for stock preparation ahead of the paper machine headbox, a critical area for sheet formation quality.

- Pulp Mill Chemical Recovery Boiler: As part of the safety and combustion control system, this module might interface with critical temperature, pressure, and flow measurements, executing interlocks to prevent hazardous conditions.

- Minerals Processing Flotation Cell Control: Could function as an I/O module or local controller managing reagent dosing valves and air flow based on analyzer inputs to optimize mineral recovery.

- Power Plant Boiler Auxiliary Control: Might be used in the sootblower sequencing or ash handling system control within a biomass or coal-fired power plant.

Comparison with Competing Products

When compared to using generic PLC or DCS components from other manufacturers, the METSO D100314 represents a vertically integrated, specialized solution:

- Specialized vs. General Purpose: The METSO D100314 is part of a system designed specifically for process industries like pulp and paper. A general-purpose PLC from Siemens or Allen-Bradley offers flexibility but lacks the pre-engineered application blocks and industry-specific tuning inherent in the Metso platform.

- Proprietary Ecosystem vs. Open Integration: Metso systems offer a tightly integrated, vendor-managed ecosystem. This can simplify engineering and support but may limit third-party integration options compared to more open DCS platforms. The D100314 module’s value is highest within its native system.

- Legacy Maintenance vs. Modern Features: This part number likely belongs to a mature or legacy system. Its primary “competition” is not another brand, but the decision to continue maintaining the existing system versus investing in a migration to Valmet’s newer (e.g., DNA) or a different vendor’s contemporary platform.

Selection Advice and Important Notes

- Confirm Exact Function and Compatibility: This is the most critical step. The part number D100314 alone is insufficient. You must obtain the technical data sheet or parts manual for your specific Metso system to verify this component’s exact function (CPU, I/O, comms) and its compatibility with your chassis, backplane, and system firmware version.

- Source from Authorized Channels: Due to the critical nature of these components in process plants, procure the METSO D100314 module only from Valmet Automation or authorized distributors to ensure authenticity, correct firmware, and valid support.

- Requires Specialized Knowledge: Installation, configuration, and troubleshooting of this module require training on Metso/Valmet’s specific engineering software and hardware practices. This is not a task for general automation technicians.

- Backup Configuration Before Replacement: If replacing a module in a live system, always ensure a complete and verified backup of the system configuration and application software exists before removing any hardware.

- Assess System Lifecycle Stage: Before investing in a legacy component like the D100314, evaluate the overall lifecycle status of your automation system. Develop a long-term strategy for eventual migration or renewal to avoid being stranded without support.

6SE7032-7EB87-2DA0

6SY7010-0AB42 PLC

6SY7010-0AB43

6GK1105-2AB10 PLC

63-23-730-8 PLC

CACR-SR20BE12F

A06B-6110-H030

CIMR-F7U42P2 plc

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922