Description

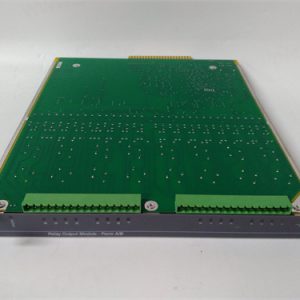

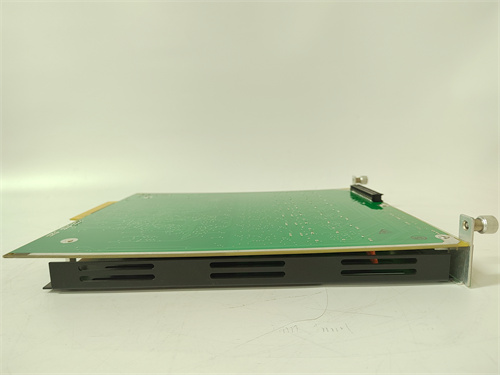

METSO IOP320 is a high-performance I/O processor module designed for METSO DNA distributed control systems (DCS), specializing in seamless signal conversion, data acquisition, and control command execution in process industries. METSO IOP320 integrates multi-type I/O channels and supports mainstream industrial protocols, enabling reliable connectivity between field sensors/actuators and upper-layer PLC/DCS. METSO IOP320 features rugged industrial-grade design with strong anti-interference capabilities and electrical isolation, ensuring stable operation in harsh environments with temperature fluctuations and electromagnetic interference. METSO IOP320 offers flexible configuration and hot-swap functionality, facilitating system expansion and maintenance without production downtime. Whether deployed in mineral processing plants or petrochemical refineries, METSO IOP320 delivers precise and reliable I/O processing for mission-critical automation workflows.

Technical Parameters METSO IOP320

| Parameter Item | Parameter Value |

|---|---|

| Product Model | METSO IOP320 |

| Module Type | Industrial I/O Processor Module |

| Compatible System | METSO DNA Distributed Control System (DCS) |

| I/O Channels | 16 analog inputs, 16 analog outputs, 32 digital inputs, 32 digital outputs (expandable via backplane bus) |

| Input Voltage | 24VDC (dual redundant input, automatic switching) |

| Analog Channel Precision | 0.1% FS |

| Digital Response Time | ≤1ms |

| Communication Interfaces | Ethernet, RS485, Modbus TCP/IP, Profinet |

| Communication Rate | Up to 100Mbps (data update rate 50ms) |

| Isolation Rating | 2500VAC (input/output to bus) |

| Surge Protection | IEC 61000-4-5, 2kV |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -40°C to +90°C |

| Dimensions | 100mm×80mm×25mm |

| Weight | 150g |

| Mounting Type | DIN rail |

| Certifications | CE, RoHS |

| Protection Features | Over-voltage, over-current protection |

Advantages and Features METSO IOP320

- Rich I/O Expansion Capability: METSO IOP320 offers abundant analog and digital channels with expandable design, meeting diverse signal acquisition and control needs without additional adapter modules.

- High Precision Signal Processing: 0.1% FS analog channel precision ensures accurate conversion of process parameters like temperature and pressure, supporting precise industrial process control.

- Strong Anti-Interference Performance: 2500VAC electrical isolation and 2kV surge protection minimize electromagnetic interference impact, reducing misoperation rate to ≤0.001% in high-noise environments.

- Multi-Protocol Compatibility: Supports Ethernet, RS485, Modbus TCP/IP, and Profinet, enabling seamless integration with mainstream PLCs (Siemens S7-1200/1500, ABB AC800M) and DCS systems.

- Reliable and Maintainable Design: Hot-swap support and redundant power input ensure 99.99% system availability, while modular structure simplifies maintenance and reduces downtime.

Application Cases

- Automotive Assembly Line Conveyor Control: An automotive plant deployed METSO IOP320 to connect 24 photoelectric sensors and 16 proximity switches, refreshing input status every 10ms. It drives 12 relays to control conveyor motors, ensuring ±2mm workpiece positioning accuracy and improving production line synchronization by 18%.

- Municipal Sewage Treatment Aeration Control: A sewage treatment facility used METSO IOP320 to collect 8 dissolved oxygen (4-20mA) and 4 pH sensor signals. It adjusts 16 aeration valve openings with 4-20mA output, stabilizing dissolved oxygen concentration at 2-3mg/L with ±0.2mg/L precision and reducing energy consumption by 22%.

- Mineral Processing Plant Grinding Control: A mineral processing plant integrated METSO IOP320 into its grinding system, monitoring temperature, pressure, and flow signals. Its strong anti-interference capability ensures stable operation in the high-vibration environment, reducing equipment failure-related downtime by 30%.

Competitor Comparison

| Comparison Item | METSO IOP320 | Siemens ET 200SP I/O Module | ABB CI854A Communication Interface |

|---|---|---|---|

| Module Type | I/O Processor Module | Distributed I/O Module | Communication I/O Module |

| I/O Channel Expansion | 16AI+16AO+32DI+32DO (expandable) | 8AI+8AO+16DI+16DO (expandable) | Limited to communication-focused I/O |

| Analog Precision | 0.1% FS | 0.2% FS | 0.15% FS |

| Operating Temperature | -40°C to +85°C | -20°C to +60°C | -30°C to +70°C |

| Communication Protocols | Modbus TCP/IP, Profinet, Ethernet, RS485 | PROFINET, Ethernet/IP | Modbus, Profinet |

| Isolation Rating | 2500VAC | 1500VAC | 2000VAC |

| Estimated Price (USD) | ~$1,100 | ~$1,250 | ~$1,300 |

Selection Suggestions

- Choose METSO IOP320 for METSO DNA DCS systems, leveraging seamless integration and optimized compatibility for process control applications.

- Opt for METSO IOP320 in harsh environments (-40°C to +85°C) such as mining or outdoor industrial sites, as its wide operating temperature range outperforms competitors.

- Select METSO IOP320 for projects requiring high-precision signal processing (0.1% FS) and rich I/O channels, such as automotive manufacturing or sewage treatment.

- Use METSO IOP320 for multi-vendor system integration, as its multi-protocol support eliminates compatibility issues with mainstream PLCs and DCS.

Precautions

- Ensure input voltage is strictly 24VDC to avoid damaging METSO IOP320; utilize redundant power input for critical applications.

- Mount the module on a standard DIN rail with adequate ventilation, avoiding direct exposure to moisture and corrosive gases.

- Use shielded cables for I/O wiring to enhance anti-interference performance, especially in environments with heavy electromagnetic interference.

- Do not exceed the rated current of I/O channels to prevent module damage and ensure signal stability.

- Follow ESD protection protocols (anti-static wristband, mat) when handling METSO IOP320 to protect internal components.

- Regularly update firmware via communication interfaces to maintain compatibility with latest control system software and unlock new features.

EPRO UES815S

EPRO CON021

EPRO PR6424/010-000

EPRO PR6424/010-000

EPRO PR6423/010-010

EPRO PR6424/010-131+CON031

EPRO PR6424/012-000

EPRO PR6423/10R-030-CN

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922