Description

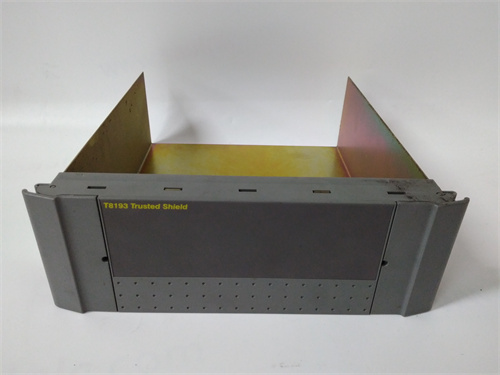

Product Description

Product Parameters

| Parameter | Details |

|---|---|

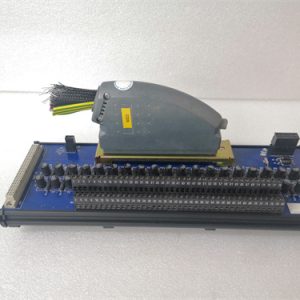

| Module Type | Digital I/O & Chassis Blanking Module (ICS TRIPLEX T8193) |

| Core Function | Digital signal input/output; T8100 chassis slot protection; safety-critical system integration |

| I/O Channels | 16 configurable digital channels (input/output) |

| Signal Type | Digital (on/off) |

| Power Supply | Input: 24VDC; Output: 5VDC |

| Operating Temperature | -40°C to 85°C |

| Humidity Range | 5-95% RH (non-condensing) |

| Supported Protocols | Ethernet, Modbus TCP/IP |

| Programming Languages | Ladder logic, function block diagram |

| Certifications | IEC 61508 SIL 3, TÜV certified |

| Dimensions | 100mm × 50mm × 20mm |

| Weight | 100g |

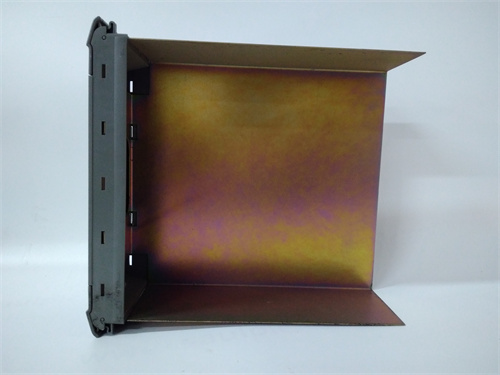

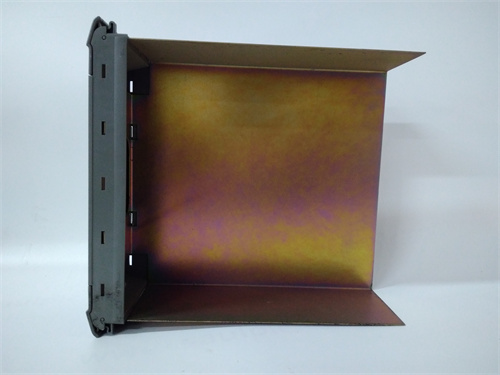

| Installation | T8100 chassis slot (functional or blanking use) |

| Compatibility | PLC/DCS systems, third-party software tools |

Advantages and Features

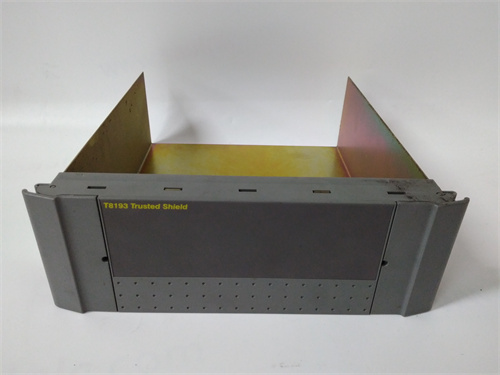

- Dual-Functional Versatility: ICS TRIPLEX T8193 combines digital I/O functionality with chassis blanking protection, reducing the need for separate specialized components.

- Harsh Environment Resilience: Wide temperature range (-40°C to 85°C) and physical protection design resist extreme conditions, dust, and moisture in industrial settings.

- Safety-Certified Reliability: SIL 3 compliance and TÜV certification meet strict safety requirements for critical processes in high-risk industries.

- Seamless Integration: Multi-protocol support and programmable logic enable flexible adaptation to existing control systems and custom control scenarios.

- Compact & Easy Installation: Small form factor and tool-free mounting simplify integration into T8100 chassis, whether as a functional module or blanking plate.

- System Integrity Protection: Fills vacant chassis slots to prevent module loosening and protect internal electronic components from external contaminants.

Application Cases in Application Fields

- Nuclear Power Plant: ICS TRIPLEX T8193 served as both a blanking module for T8100 chassis and a digital I/O module to monitor safety switch status, leveraging SIL 3 certification and wide temperature tolerance for reliable operation in critical areas.

- Petrochemical Refinery: It integrated into the ESD system to process pipeline sensor signals and drive emergency valves, while filling vacant chassis slots to maintain system integrity in dusty, high-vibration environments.

- Offshore Drilling Platform: ICS TRIPLEX T8193 handled fire and gas system signal input/output and protected chassis slots from marine humidity, with Modbus TCP/IP support ensuring seamless communication with the main control system.

- Thermal Power Generation Facility: It controlled auxiliary system actuators and filled unused chassis slots, maintaining stable performance under high-temperature conditions and reducing system downtime by preventing component contamination.

Comparisons with Competing Products

| Parameter | ICS TRIPLEX T8193 | Siemens 3DI851-6AB00 (SIL 3) | ABB 800xA DI890 |

|---|---|---|---|

| Module Type | Digital I/O + Chassis Blanking | Digital Input Module | Safety Digital Input Module |

| I/O Channels | 16 (configurable) | 16 (input only) | 16 (input only) |

| Dual Function | Yes (I/O + blanking) | No | No |

| Operating Temp | -40°C to 85°C | -25°C to 60°C | -40°C to 70°C |

| Supported Protocols | Ethernet, Modbus TCP/IP | Profinet, Modbus | Ethernet/IP, Modbus |

| Safety Certification | IEC 61508 SIL 3 | IEC 61508 SIL 3 | IEC 61508 SIL 3 |

| Dimensions | 100mm × 50mm × 20mm | Compact modular | Standard modular |

Selection Suggestions and Precautions

Selection Suggestions

- Choose ICS TRIPLEX T8193 for SIL 3-certified systems needing dual functionality (digital I/O + chassis protection), harsh environment resistance, and flexible integration with T8100 chassis.

- Prioritize it for nuclear power, petrochemical, offshore, and power generation applications where both signal processing and system integrity protection are critical.

Precautions

- Use 24VDC input power to ensure stable operation of ICS TRIPLEX T8193 and avoid voltage mismatches.

- Confirm installation purpose (functional I/O or blanking) and configure channels accordingly to match field device requirements.

- Ensure proper seating in T8100 chassis slots to maintain chassis integrity and prevent dust/moisture ingress.

- Regularly inspect the module for physical damage or contamination, especially in high-dust or humid environments.

- Verify compatibility with existing PLC/DCS systems and programming tools before integration to ensure seamless communication.

3500/90 Bently PLC

140471-01 Bently PLC

330709-000-060-10-02-00 Bently PLC

330730-040-01-00 Bently PLC

330130-040-00-00 Bently PLC

330103-00-03-05-02-05 Bently PLC

1X35869 Bently

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922