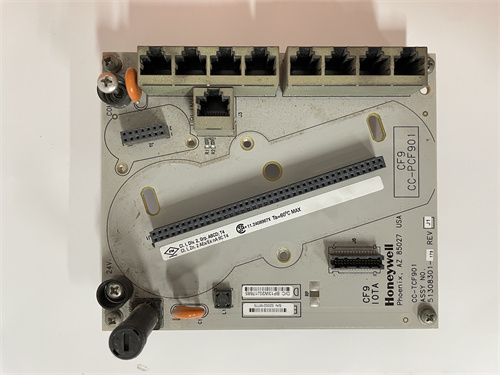

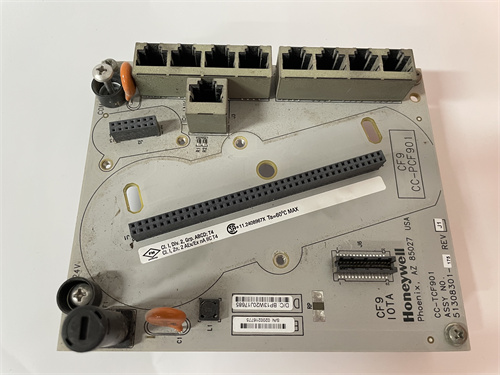

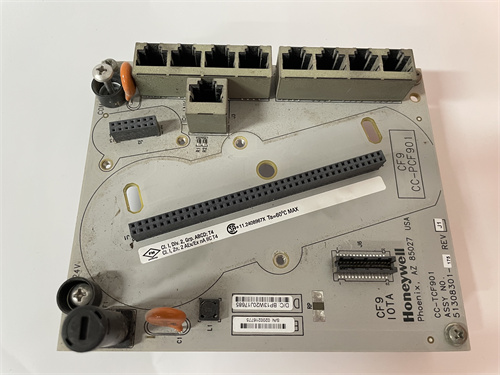

Description

Detailed Overview of the Honeywell TC-CCR013 Controller Module

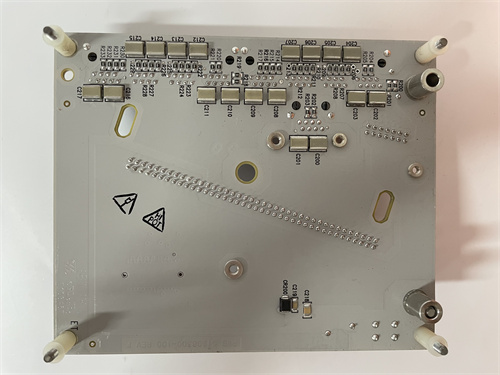

Product: Honeywell TC-CCR013 is a high-performance Controller Module designed for Honeywell’s Experion® Process Knowledge System (PKS), specifically for use within the C300 Process Controller family. This module, the TC-CCR013, serves as the central processing brain of a control domain, executing regulatory control logic, sequence operations, and safety interlocks for a portion of a process unit. The deployment of a Honeywell TC-CCR013 enables sophisticated process automation with deterministic performance, high availability, and seamless integration across the Experion PKS environment.

Core Technical Parameters

- Module Type: Controller Processor Module for Experion C300.

- Processing Power: Features a powerful dedicated processor for executing control strategies built in the Control Builder engineering studio. It handles PID loops, sequencing, calculations, and communications.

- Memory: Contains significant memory for storing the control application, historical data, and system configuration.

- Redundancy Support: Designed to operate in a redundant (hot-backup) pair with an identical module. In this configuration, the TC-CCR013 actively synchronizes with its peer to ensure bumpless failover in the event of a primary controller failure.

- Communication Interfaces: Integrates with the Experion system via:

- Control Network (CNI): For communication with other controllers and the Experion servers.

- I/O Network (FTE/RIO): For high-speed, deterministic communication with I/O modules (like Universal I/O) in remote or local chassis.

- Fault Tolerance: Includes extensive self-diagnostics and fault detection to maintain process integrity and initiate safe actions or failovers when necessary.

Key Advantages and Features

- Deterministic Control Performance: The Honeywell TC-CCR013 is engineered for precise, repeatable execution of control loops with a fixed scan rate. This is critical for maintaining stable process variables like pressure, temperature, and flow in continuous processes.

- High Availability through Seamless Redundancy: Its native support for 1:1 hot redundancy ensures near-zero downtime for the controlled process. The failover is automatic and transparent to the process, a key requirement for critical units in refining, chemicals, and power generation.

- Scalable and Integrated Architecture: As part of the C300 family, the TC-CCR013 can scale from managing a small unit to being part of a large, distributed control strategy across multiple controllers. Its integration with the Experion suite is seamless, from engineering in Control Builder to operation in the Experion station.

- Advanced Control Capabilities: Beyond basic PID, the controller supports complex control strategies, model-based control, and integration of third-party algorithms, allowing for optimization of process efficiency and yield.

Application Use Cases in Various Industries

- Oil Refining: Controlling complex units such as Fluid Catalytic Cracking (FCC) units, crude distillation columns, or hydrotreaters, where reliable, fast control is essential for safety and profitability.

- Chemical Manufacturing: Executing batch recipes for polymerization reactors, managing continuous distillation trains, or controlling exothermic reaction stages.

- Power Generation (Thermal): Performing combustion control for boilers, managing turbine start-up sequences, and coordinating balance-of-plant systems in coal or gas-fired power stations.

- Pharmaceutical & Biotech: Providing precise environmental control (temperature, pressure, flow) in bioreactors and purification skids, and executing validated batch sequences.

Comparison with Competing Products (e.g., Emerson, Siemens)

| Parameter | Honeywell TC-CCR013 (Experion C300 Controller) | Comparable: Emerson DeltaV S-series Controller | Comparable: Siemens SIMATIC PCS 7 AS-410 Controller |

|---|---|---|---|

| System Architecture | Part of a tightly integrated DCS with a unified database and engineering environment (Experion PKS). | Part of a modular, characterizable I/O-based DCS with integrated control network. | Part of a DCS based on Siemens PLC hardware and PCS 7 software, utilizing a centralized/ decentralized architecture. |

| Engineering Approach | Object-oriented control strategies within Control Builder. Emphasis on pre-built templates and integration. | Function block programming in the DeltaV environment with a strong focus on device integration and diagnostics. | Programming in Continuous Function Chart (CFC) and Sequential Function Chart (SFC) within the PCS 7 engineering system. |

| Key Strength | Deep integration across the entire Honeywell ecosystem (control, safety, asset management), strong in large, complex process units. | Exceptional ease of use, modularity, and speed of implementation, particularly for mid-sized projects and expansions. | Powerful integration with Siemens drives and motor control, and robust performance for very high-speed process requirements. |

Selection Advice and Important Considerations

- System Sizing and Capacity: The TC-CCR013 has limits on the number of I/O points, control modules, and scan rate. Ensure your process application’s size and complexity are within the controller’s capacity by consulting the technical specifications during the design phase.

- Redundancy is Not Automatic: While the module supports redundancy, it requires a specific license, a redundant chassis configuration, and a correctly configured peer controller. Redundancy must be explicitly designed and commissioned.

- Firmware and Software Compatibility: The controller’s firmware must be compatible with the version of Experion software (Control Builder, Server) used in the project. Always check the Honeywell Product Compatibility Matrix before integration or replacement.

- Heat and Power Management: The controller module generates heat. Ensure the controller chassis is installed in a well-ventilated cabinet and that the system power supply is adequately sized for the fully loaded chassis, including the TC-CCR013 and all I/O modules.

- Procurement and Support Source: For guaranteed performance, compatibility, and access to firmware updates, the Honeywell TC-CCR013 must be sourced from authorized Honeywell Process Solutions distributors or directly from Honeywell. This ensures you receive genuine hardware with the correct version and full access to technical support and documentation critical for system integration and lifecycle support.

- TC-CCR013

1771-IB AB PLC

1771-IBD AB PLC

1771-IC AB PLC

1771-ID AB PLC

1771-ID16. AB PLC

1771-IFEK AB

1784-PCIC AB PLC

1771-NOC AB PLC

1771-NOV AB EC

1771-NR AB

1771-NT1 AB PLC

1771-NT2 AB PLC

1771-0A AB PLC

1771-0AD AB PLC

1771-IFMS AB

1771 -IGDA AB

1771-IH AB

1771-IL AB

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922