Description

Detailed Overview of the Honeywell SPS5710-2-LF 51198685-100 Safety Controller

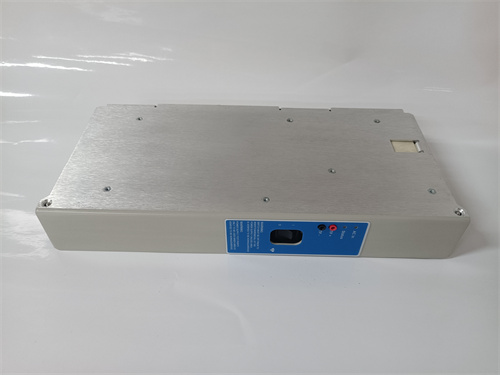

Product: Honeywell SPS5710-2-LF 51198685-100 is a specific, fully-qualified part number for a central processing unit within the Honeywell (formerly HIMA) PSSuniversal Programmable Safety System family. The suffix detail indicates this is a precise revision or variant of the base SPS5710 model. This controller, the SPS5710-2-LF, is engineered to execute certified safety logic for the most critical applications, such as Emergency Shutdown (ESD), Fire & Gas (F&G), and Turbine Machinery Control (TMC). Deploying the Honeywell SPS5710-2-LF 51198685-100 ensures the implementation of a SIL 3/SIL 4 capable safety system with deterministic performance and extensive diagnostic capabilities.

Core Technical Parameters

- Module Type: Safety Programmable Logic Controller (Safety PLC) Central Unit.

- Safety Standards: Certified for Safety Integrity Level 3 and 4 (SIL 3/4 per IEC 61508/61511) and Performance Level e (PL e per ISO 13849-1).

- Architecture: Based on a fault-tolerant 2oo2D (Two-out-of-Two with Diagnostics) hardware architecture. Two microprocessors execute the same program in parallel with continuous cross-comparison and sophisticated self-testing to detect and manage failures.

- Memory Configuration: The specific suffix (-2-LF) likely denotes a particular memory size or firmware variant. The part number 51198685-100 confirms the exact factory configuration, which is critical for replacement and compatibility.

- Communication Interfaces: Features multiple integrated communication ports supporting both safety protocols (e.g., PROFIsafe, Open SAFETY) and standard fieldbus/industrial Ethernet protocols (e.g., PROFIBUS DP, Ethernet/IP, Modbus TCP) for seamless integration with higher-level systems.

- Programming: Configured and programmed using the dedicated Honeywell Safety Builder engineering tool, which uses certified function blocks and ensures the integrity of the safety application.

Key Advantages and Features

- Highest Safety Integrity for Critical Processes: The primary advantage of the Honeywell SPS5710-2-LF is its certification for the highest Safety Integrity Levels. It is designed to manage risk in processes where the consequences of failure are severe, providing a robust and verifiable layer of protection.

- Deterministic Performance and High Diagnostic Coverage (DC): The controller offers predictable, scan-time consistent execution of safety logic. Its advanced diagnostics can detect over 99% of dangerous hardware failures, a key requirement for achieving high SIL levels, making the SPS5710-2-LF exceptionally reliable.

- Comprehensive Event and Fault Logging: It provides a detailed, time-synchronized event log with first-out fault indication. This is invaluable for incident analysis, proof testing, and predictive maintenance, reducing mean time to repair (MTTR).

- Flexible Connectivity while Maintaining Safety: The module’s ability to communicate on both safety and standard networks allows it to seamlessly exchange data with DCS/SCADA systems for operator visibility and alarm management, while the safety network remains segregated and protected to maintain its integrity.

Application Use Cases in Various Industries

- Oil & Gas (Offshore/Onshore): As the central logic solver in an Emergency Shutdown (ESD) system for a full offshore platform or a liquefied natural gas (LNG) train, where system failure could be catastrophic.

- Chemical & Petrochemical: The core of a Safety Instrumented System (SIS) protecting large, continuous catalytic crackers or high-pressure polymerization reactors.

- Power Generation: Used for Turbine Machinery Control (TMC) and overspeed protection on large gas or steam turbines in combined-cycle power plants.

- Rail Transportation: Vital control systems for railway interlocking and automatic train protection (ATP) where SIL 4 certification is required.

Comparison with Competing Products (e.g., Siemens, ABB)

| Parameter | Honeywell SPS5710-2-LF (PSSuniversal System) | Comparable: Siemens SIMATIC S7-410F/H | Comparable: ABB AC 800M HI (High Integrity) |

|---|---|---|---|

| Heritage & Focus | Originates from HIMA, a company dedicated solely to safety technology. Focus is on maximum separation and integrity for process safety. | An integrated safety CPU within the high-end S7-400 automation platform, focused on combining process control and safety. | A high-integrity variant of ABB’s flagship DCS controller, designed for tight integration of control and safety within the same system architecture. |

| Typical Deployment | Often deployed as a standalone, independent Safety Instrumented System (SIS), physically separate from the Basic Process Control System (BPCS). | Often used in integrated architectures where safety and standard control share infrastructure within a single rack or system. | Used in unified architectures where the safety and control applications run on different partitions of the same hardware platform. |

| Key Strength | Proven, independent safety pedigree with top-level SIL 4 certification. Preferred in industries where regulatory frameworks or company standards mandate a clearly independent safety system. | Powerful integration within the TIA Portal for large-scale industrial applications requiring complex interplay between safety and standard logic. | Optimized synergy between the BPCS and SIS, offering a single engineering and operator environment which can reduce lifecycle costs. |

Selection Advice and Important Considerations

- Exact Part Number Matching is Critical: For replacement or spares, the full part number Honeywell SPS5710-2-LF 51198685-100 must be matched exactly. Variations in suffix can indicate differences in firmware, memory, or hardware revision that affect compatibility with the existing baseplate, I/O, and project software.

- Requires a Full Safety Lifecycle Approach: Implementing or modifying a system based on this controller is not a simple programming task. It must follow the IEC 61511 safety lifecycle, including Hazard and Risk Analysis, Safety Requirements Specification (SRS), and formal Functional Safety Assessment (FSA).

- Specialized Engineering Tools and Skills: Configuration requires Honeywell Safety Builder software and engineers certified in functional safety. The application logic must be developed and validated using certified function blocks.

- System Design (Redundancy, Voting): The SPS5710-2-LF can be deployed in simplex, redundant (1oo2), or fault-tolerant configurations. The system architecture (sensor voting, final element voting) must be designed to meet the target Safety Availability (PFDavg) defined in the SRS.

- Procurement Source: Given its safety-critical nature, the Honeywell SPS5710-2-LF 51198685-100 must be sourced exclusively from authorized Honeywell (HIMA) safety distributors or directly from the manufacturer. This guarantees authenticity, receives the correct firmware, ensures full traceability, and provides access to the essential technical support and documentation required for system validation and certification.

- SPS5710-2-LF

1769-OF8C AB

1769-OF8V AB PLC

1769-0G16 AB PLC

1769-0V32T AB PLC

1769-0W16 AB PLC

1769-0W8 AB PLC

1769-0W8I AB CPU

1769-PA2 AB

1769-PB4 AB

1769-PA4 AB

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922