Description

Product Description

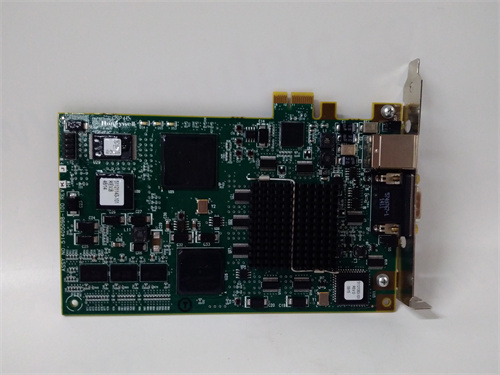

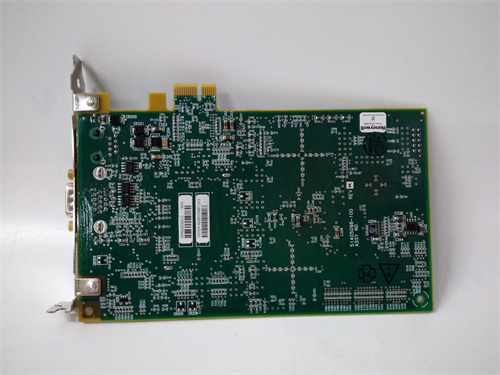

HONEYWELL LCNP4E is a Local Control Network (LCN) Interface Module for the Honeywell TDC 2000/3000 distributed control system. This module, the LCNP4E, is a critical communication card that serves as the gateway between a TDC system’s Universal Control Network (UCN) and the higher-level plant-wide Local Control Network (LCN). Its primary function is to enable a Honeywell Advanced Process Manager (APM) or other UCN-based process controller to communicate with LCN devices such as the Universal Station (operator console), History Module, and Application Module. The HONEYWELL LCNP4E translates data and commands between the two proprietary Honeywell networks, allowing for centralized operator control, data logging, and advanced application processing. In the hierarchy of a TDC system, the LCNP4E module is an essential component for integrating process control with plant-wide supervision and management.

Product Parameters / Technical Specifications

- Manufacturer: Honeywell

- System: TDC 2000 / TDC 3000 Distributed Control System (DCS)

- Functional Designation: LCN Interface Module for UCN Nodes (specifically, a “P4” series card).

- Network Interface:

- LCN Port: Connects to the coaxial-cable based Local Control Network (LCN) running at 5 Mbps.

- UCN Port: Connects to the Universal Control Network (UCN) for communication with the attached process manager (APM, HPM, etc.).

- Form Factor: A large, proprietary circuit board designed to plug into a specific slot within the process manager’s cabinet.

- Node Address: Configured with a unique LCN node address, which identifies the attached process manager on the plant-wide LCN.

- Functions: Handles time synchronization, data buffering, protocol conversion, and error checking between the LCN and UCN networks.

- Status Indicators: Features status LEDs for power, network activity, and faults.

Advantages and Key Features

- Legacy System Integration: The HONEYWELL LCNP4E was the vital link that enabled Honeywell’s UCN-based controllers to participate in the larger, plant-wide TDC 3000 system, creating a unified control and information architecture.

- Deterministic Communication: Provided reliable, time-synchronized data exchange between the process control level and the operator/historian level, which was essential for coordinated plant operation.

- Gateway Functionality: Acted as a sophisticated gateway, offloading network protocol handling from the main process manager CPU and improving overall system performance.

- Robust Hardware Design: Built with the ruggedness expected for 24/7 industrial operation in control room environments.

- Established Technology: For decades, this module was a cornerstone of thousands of TDC installations worldwide.

Application Cases in Industry

- TDC 3000 System Expansion: Used when adding a new Advanced Process Manager (APM) or History Module to an existing TDC 3000 LCN network in a refinery, chemical plant, or pulp & paper mill.

- Legacy System Maintenance: Serves as a critical spare part for maintaining operational TDC systems where the LCNP4E module has failed, restoring communication between a control cabinet and the operator consoles.

- Plant-Wide Data Integration: Enabled the process data from individual units (controlled by APMs) to be visible on universal stations across the plant and recorded in the system’s history modules.

Comparison with Competing Products

| Feature | HONEYWELL LCNP4E (TDC 3000 LCN Interface) | Modern OPC Server / Gateway |

|---|---|---|

| Technology Era | 1980s-1990s Proprietary DCS: Part of a closed, hardware-based network architecture using custom protocols and coaxial cabling. | 2000s-Present Open Standards: Uses standard Ethernet, Windows/Unix servers, and open protocols (OPC UA, Modbus TCP) to bridge systems. |

| Integration Level | Hardware-Integrated Gateway: A dedicated hardware card that is an integral part of the controller’s physical architecture. | Software-Based Bridge: A software application running on a standard server that communicates with controllers via their available ports. |

| Performance & Determinism | Deterministic & Hardware-Optimized: Performance was guaranteed by the dedicated hardware and network design. | Network & Software Dependent: Performance depends on server resources, network load, and software configuration. |

| Modern Relevance | Legacy Maintenance Only: Used exclusively for supporting existing, aging TDC systems. No new development. | Current Integration Standard: The primary method for integrating modern and legacy systems in today’s plants. |

Selection Suggestions and Precautions

- Confirm System Architecture Compatibility: The HONEYWELL LCNP4E is only for TDC 2000/3000 systems with a UCN network. Verify your system uses UCN-based process managers (APM, HPM) and not later Experion systems.

- Exact Module Revision: There were multiple revisions of LCN interface cards (P2, P4, etc.). The LCNP4E must be the correct revision specified for your process manager model and TDC software release. Using an incompatible card can cause communication failures.

- LCN Network Address: Each module must have a unique LCN node address. Before replacing a card, record the address setting from the old module (often via switches) and configure the new LCNP4E identically. Duplicate addresses will crash the LCN segment.

- Handle with Extreme Care (ESD & Physical): These are large, static-sensitive, legacy cards. Use proper ESD protection. Be very careful with the edge connectors and the card’s weight during handling.

- Full System Impact: Replacing this card will sever the communication link between that process manager and the rest of the DCS. This is a major activity that requires a well-planned outage window for the associated process unit.

- Sourcing from Legacy Specialists: The TDC platform is obsolete. Source the LCNP4E from vendors who specialize in legacy Honeywell DCS support. They can often provide tested/refurbished cards with a warranty and may offer technical guidance for installation.

UT374c-E HONEYWELL PLC

UT373a HONEYWELL

UT372c HONEYWELL PLC

UT371aV2 HONEYWELL

UT370aV2 HONEYWELL

UB7391b-E HONEYWELL PLC

UB371a-E HONEYWELL PLC

UA379A-E HONEYWELL PLC

UA374B-E HONEYWELL

UA383a-E HONEYWELL PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922