Description

Product Description

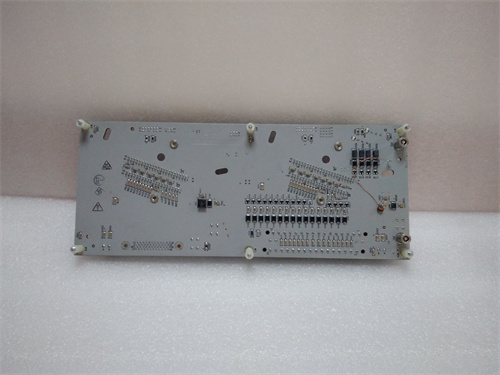

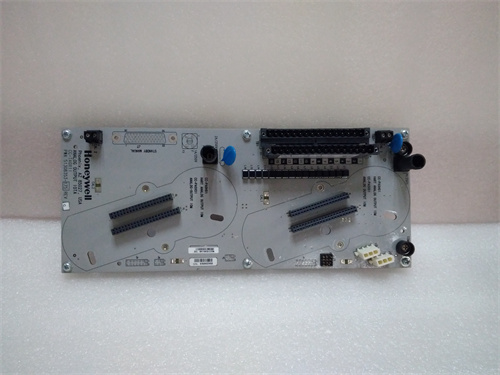

HONEYWELL CC-TAOX11 is an Analog Output Module for the Honeywell Experion Process Knowledge System (PKS) and earlier TPS systems, utilizing the C Series I/O architecture. This module is a critical interface within a C Series I/O pack that executes control commands by converting digital values from the Experion controller into precise analog signals for field devices. The primary function of the HONEYWELL CC-TAOX11 is to provide a reliable, isolated 4-20 mA output signal to command final control elements such as control valve positioners, variable frequency drive (VFD) speed references, or analog chart recorders. It serves as the vital link that translates the control system’s calculated setpoints into physical action in the process. The accuracy and reliability of modules like the CC-TAOX11 are fundamental to maintaining stable and responsive regulatory control loops.

Product Parameters / Technical Specifications

- Manufacturer: Honeywell

- System: Experion PKS / TPS (C Series I/O)

- Functional Designation: Analog Output Module (4-20 mA)

- Output Type: 4-20 mA DC (current output).

- Output Channels: Typically provides 4 or 8 isolated output channels per module (specific channel count to be verified for the CC-TAOX11 variant).

- Output Load: Capable of driving a specific maximum load resistance (e.g., 750 Ohms, 1000 Ohms), which defines the maximum loop impedance it can work with.

- Accuracy: High accuracy, typically better than ±0.1% of full scale, ensuring precise command signal generation.

- Isolation: Channel-to-channel and channel-to-system isolation to prevent ground loops and fault propagation.

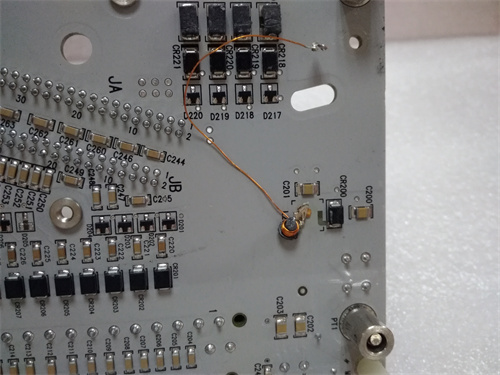

- Diagnostics: Includes output circuit diagnostics such as short-circuit detection, open-loop detection, and module health monitoring.

- Communication: Interfaces with the Experion controller via the C Series I/O bus when installed in a compatible carrier module (e.g., CC-PCF901).

- Power Supply: Receives power from the carrier module. The module itself may provide the sourcing voltage for the 4-20 mA loop (sourcing output).

Advantages and Key Features

- High Reliability and Precision: Engineered for stable, long-term operation in process control applications where output signal drift can directly impact product quality or process safety.

- Integrated Diagnostics: The ability to detect wiring faults like shorts or opens on the output loop provides valuable predictive maintenance data and prevents situations where a control valve is not responding to commands.

- Hot-Swappable Design: Supports online insertion and removal (subject to carrier and system design), allowing for module replacement without a process shutdown, which is critical for plant availability.

- Seamless Experion Integration: Fully configured and monitored within the Honeywell Control Builder engineering environment. Output points are part of the unified system database, simplifying configuration and alarming.

- Robust Industrial Design: Built to withstand the electrical noise and environmental conditions of industrial settings, ensuring consistent performance.

- Proven Performance in Critical Loops: Commonly used in demanding regulatory control applications within Honeywell’s installed base.

Application Cases in Industry

- Control Valve Positioning: The primary application for the HONEYWELL CC-TAOX11 is to send a 4-20 mA signal to the positioner of a control valve to regulate flow, pressure, or level in refining, chemical, and petrochemical processes.

- Variable Speed Drive Control: Provides the speed reference signal (4-20 mA) to a VFD controlling a pump, fan, or compressor motor as part of a flow or pressure control loop.

- Analog Setpoint Transmission: Sends an analog signal as a remote setpoint to standalone controllers or recording devices.

- Fuel and Air Ratio Control: Used in burner management and combustion control systems to command fuel valves or air dampers.

Comparison with Competing Products

| Feature | HONEYWELL CC-TAOX11 (Experion C Series I/O) | Generic PLC Analog Output Module |

|---|---|---|

| System Architecture | Integrated DCS Component: Part of a proprietary, high-availability architecture with deterministic communication to dedicated controllers. Designed for seamless redundancy and hot-swap. | Modular PLC Component: Part of a flexible system where performance depends on the PLC scan cycle and network. Hot-swap capabilities vary. |

| Diagnostics & Maintenance | Advanced, System-Integrated Diagnostics: Faults (open wire, short) are reported directly into the DCS’s unified alarm system and often visible on the module’s LEDs. Replacement is a designed procedure. | Basic Diagnostics: May provide limited fault indication. Replacement procedures and system impact are less standardized. |

| Engineering Workflow | Unified Configuration in Control Builder: Hardware configuration and control strategy are linked in the same engineering tool with a single point database. | Separated Configuration: Hardware configuration and control logic programming are often distinct steps in the PLC software. |

| Target Application Focus | Critical Process Control Loops: Optimized for complex, continuous processes where loop integrity and availability are paramount. | General Automation & Control: Used for a wide range of applications, from process control to machine automation. |

Selection Suggestions and Precautions

- Verify Carrier Module Compatibility: The HONEYWELL CC-TAOX11 must be installed in a compatible C Series carrier module (e.g., CC-PCF901). Confirm the carrier type matches your system’s I/O network (FTE or legacy).

- Check Load Compatibility: Ensure the total loop impedance (wire resistance + field device input impedance) of each connected field device does not exceed the module’s specified maximum load resistance. Overloading can cause signal drop or module fault.

- Wiring Practices: Use shielded, twisted-pair cable for all analog output signals. Ground the cable shield at the DCS cabinet end only to prevent ground loops. Ensure proper terminal torque.

- Utilize Diagnostics: Enable and configure the diagnostic alarms (open wire, short circuit) in Control Builder. This provides early warning of output circuit failures.

- Output State on Fault: Understand and configure the module’s or control strategy’s behavior for a diagnosed fault. Should the output go to a safe state (e.g., 4 mA, 20 mA, or hold last value)? This is critical for safety and process requirements.

- Sourcing from Authorized or Specialized Suppliers: Given its role in critical control loops, procure the CC-TAOX11 from authorized Honeywell channels or from highly reputable surplus suppliers with specific expertise in Honeywell DCS systems.

P62400131161GA-FOXBORO

P62400161151-FOXBORO

P62400161161-FOXBORO

P77440H3N000-FOXBORO

P77440H3N300-FOXBORO

P91PA-FOXBORO

P91PAF5-FOXBORO

P91TY-FOXBORO

DS200ADGIH1AAA GE

CC-TAOX11

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922