Description

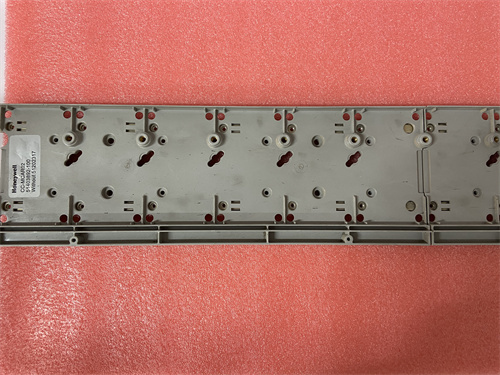

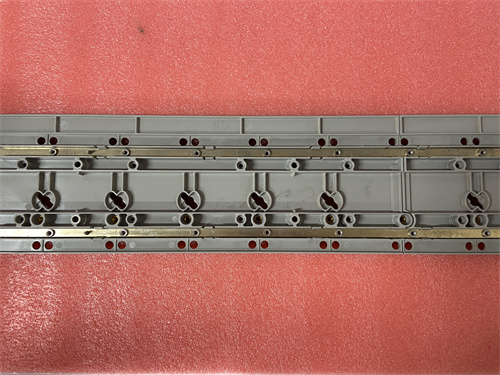

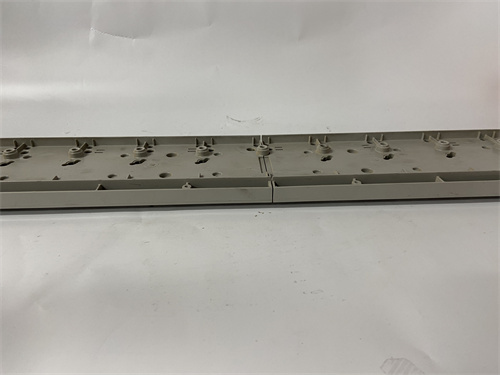

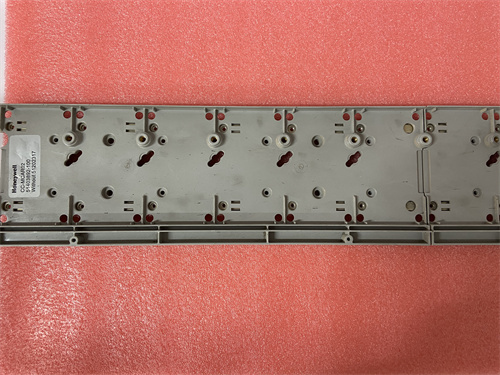

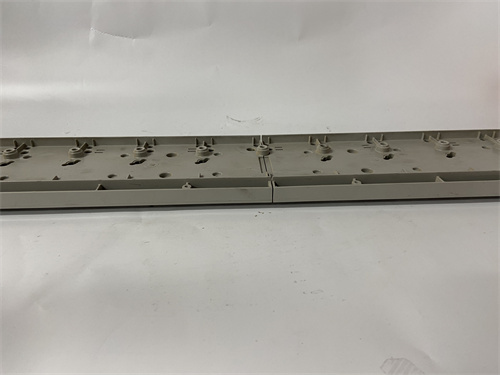

Product Description: Controller Module HONEYWELL CC-MCAR02

The HONEYWELL CC-MCAR02 is a high-performance multifunction controller module designed for Honeywell’s Experion Process Knowledge System (PKS) within the C300 Controller family. This module serves as the central processing and control execution unit within a C300 process automation controller (PAC), capable of running complex control strategies, sequence logic, and calculations for a wide range of industrial processes. As the “brain” of the controller, the HONEYWELL CC-MCAR02 is responsible for executing the user-defined application code and managing communications with I/O modules and the Experion network. For comprehensive technical specifications and configuration details, please visit the official product page: HONEYWELL CC-MCAR02. Selecting the appropriate controller module, such as the HONEYWELL CC-MCAR02, is a fundamental decision in designing a scalable and reliable control system architecture.

Key Parameters

- Core Function: Process Automation Controller (PAC) Central Module. It contains the main CPU, memory, and firmware required to execute control applications built in Honeywell’s Control Builder engineering software.

- Processing Power and Memory: Features a specific microprocessor, RAM, and flash memory capacity tailored for deterministic real-time control. The “02” suffix often indicates a performance level or memory configuration within the product family.

- Control Execution: Executes hybrid control strategies that seamlessly combine continuous regulatory control (PID loops), discrete logic, sequential control (SFCs), and advanced batch management.

- Communication Interfaces: Integrates multiple communication ports, typically including ports for connecting to the Experion Control Network (via a separate communication module like the CCNI), ports for local I/O (connecting to C-series I/O modules via the controller’s backplane), and often a service port for engineering access.

- Redundancy Support: Designed to operate in a high-availability redundant pair. Two HONEYWELL CC-MCAR02 modules can be configured for fault-tolerant operation, with automatic, bumpless switchover in the event of a primary module failure.

- Firmware and Compatibility: Runs a specific version of Honeywell’s control firmware. Compatibility with I/O modules, communication cards, and the Experion station software is strictly dependent on this firmware version.

Advantages and Features

The primary advantage of the HONEYWELL CC-MCAR02 is its deep integration and optimized performance within the Experion PKS ecosystem. It provides a powerful, deterministic platform for implementing complex control strategies with the reliability required for continuous process operations. Its support for controller redundancy is a critical feature for mission-critical applications, ensuring maximum system availability. The module’s design facilitates easy maintenance and upgrades, often supporting hot-swapping in redundant configurations. For system integrators, the HONEYWELL CC-MCAR02 offers a familiar and powerful control engine backed by Honeywell’s global support network, reducing engineering risk and lifecycle costs.

Application Case Studies in Various Fields

- Refinery Process Units: Acting as the primary controller for a Fluid Catalytic Cracking (FCC) unit or a Continuous Catalytic Reformer (CCR), managing complex interlocking, safety systems, and advanced regulatory control.

- Large Chemical Batch Reactors: Orchestrating intricate batch recipes, managing phases, tracking materials, and controlling temperature/pressure profiles for pharmaceutical or specialty chemical production.

- Power Plant Boiler Control: Implementing combustion control, feedwater control, and SOx/NOx emission control strategies with high reliability and fast response times.

- Oil & Gas Production Platforms: Centralized control for separation, compression, and gas treatment trains, often in a redundant configuration to withstand harsh environments.

- Pulp and Paper Mill Process Lines: Coordinating the distributed control of digesters, bleach plants, and paper machines from a centralized, high-performance controller.

Comparison with Competing Products

The HONEYWELL CC-MCAR02 competes with central processing units from other major DCS vendors, such as Emerson’s DeltaV CHARMS controller, Yokogawa’s CENTUM VP FCS controller, and Siemens’ PCS 7 AS-410/AS-410 H CPU. Its key differentiator is its native environment within Experion PKS, which offers a uniquely integrated suite for control, safety, and operations. Compared to using a high-end PLC for process control, the HONEYWELL CC-MCAR02 provides superior integration with advanced process control (APC) tools, a unified historian, and a more process-centric engineering environment. It represents the high-end of the process control spectrum within Honeywell’s portfolio.

Selection Suggestions and Important Precautions

- Assess Performance Requirements: Evaluate the complexity and scan rate requirements of your control strategy. Ensure the processing power and memory of the HONEYWELL CC-MCAR02 are adequate for the application, including future expansions.

- Plan for Redundancy Early: If the process requires high availability, plan for a redundant controller configuration from the initial design. This requires two HONEYWELL CC-MCAR02 modules, a redundancy cable kit, and compatible redundant I/O and communication modules.

- Verify Firmware Compatibility: The firmware version on the HONEYWELL CC-MCAR02 must be compatible with the version of Experion Station software, Control Builder, and all associated I/O and communication modules in the system. Always check the Honeywell Product Compatibility Matrix.

- Secure Physical and Network Access: The controller is a critical asset. Install it in a secure, environmentally controlled cabinet. Follow Honeywell’s security guidelines for hardening the controller and segmenting the control network.

- Maintain Configuration Backups: Always maintain secure, version-controlled backups of the controller’s application configuration loaded onto the HONEYWELL CC-MCAR02. This is essential for disaster recovery. Perform firmware updates only during planned maintenance windows and strictly according to Honeywell’s procedures. Always procure this critical component from authorized Honeywell distributors. During commissioning, thoroughly test all control strategies and verify failover functionality in redundant setups

6SL3224-0BE33-7AA0 GE PLC

3UF5031-3AN00-1 GE PLC

1FT6082-8AC71-3AA2 GE PLC

6ES5102-8MA02 GE PLC

6ES5944-7UB11 GE PLC

6ES7288-1SR40-0AA0 GE PLC

G26004-A3118-P100 GE

6ES7414-2XK05-0AB0 GE PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922