Description

Product Description

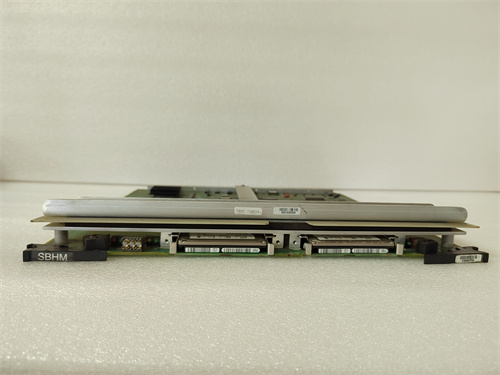

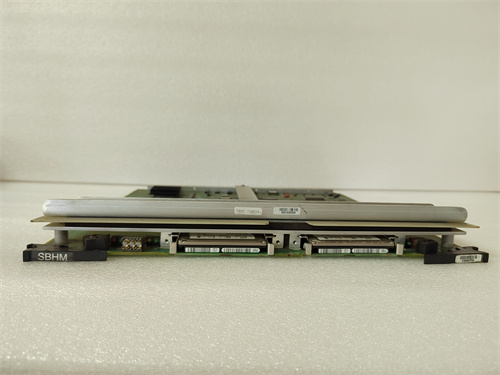

The HONEYWELL 51403645-100 SBHM is a critical system module for Honeywell’s Safety Manager series of safety instrumented systems (SIS), specifically functioning as a System Bus Hub Module (SBHM). This module acts as the central communication and coordination hub within a Safety Manager main or expansion chassis. The primary role of the 51403645-100 SBHM is to manage the high-speed, fault-tolerant Safety Bus that interconnects all critical modules within the chassis, including the processors, I/O modules, and communication interfaces. Implementing the Honeywell SBHM module is fundamental to ensuring deterministic and reliable data exchange between all components of the safety controller, which is essential for the system’s integrity and performance.

- Product Type: System Bus Hub Module (SBHM) for Safety Manager.

- Compatible Systems: Honeywell Safety Manager (SM) series main and expansion chassis.

- Primary Function: Serves as the central router and arbiter for the internal Safety Bus (a high-speed, time-synchronized, redundant backplane network).

- Bus Management: Coordinates communication between the Central Processing Modules (CPMs), I/O modules, and other system modules within the same chassis.

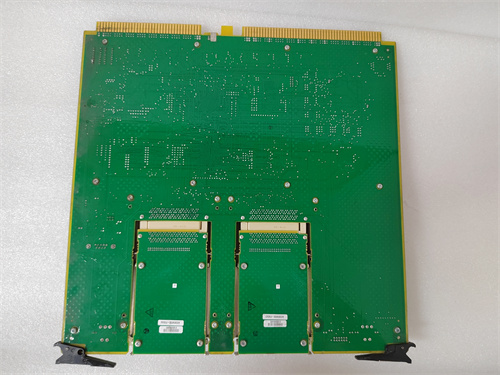

- Redundancy: Typically installed in a redundant pair (1oo2) to eliminate any single point of failure for the internal chassis communication. The modules operate in active/standby or load-sharing modes.

- Hot-Swappable: Designed to be inserted or removed from a powered and operating chassis without causing a system shutdown, supporting online maintenance.

- Diagnostics: Continuously monitors the health of the Safety Bus and its own operation. Provides extensive status LED indicators and communicates fault information to the system’s diagnostic interface.

- Mounting: Occupies designated slots in the Safety Manager chassis, usually adjacent to the processor modules.

Advantages and Features

- Fault-Tolerant Chassis Communication Core: The HONEYWELL 51403645-100 SBHM is the engineered heart of the chassis’s internal network. Its redundant design ensures that communication between critical safety components remains intact even if one hub module fails, preserving the system’s high availability.

- Deterministic and High-Speed Data Exchange: It manages the Safety Bus to provide predictable, low-latency communication essential for the fast execution of safety logic and coordination between processors and I/O. This determinism is a key requirement for certified Safety Instrumented Systems.

- Enables System Scalability and Modularity: By providing a robust internal communication backbone, the SBHM module allows the Safety Manager system to be configured with various combinations of processors and I/O modules, supporting flexible and scalable safety solutions.

- Enhanced System Diagnostics and Manageability: The module actively monitors bus traffic and health. Any degradation or fault in the internal communication path is immediately detected and reported, providing a deep level of diagnostic insight for system health monitoring.

- Seamless Integration with Safety Architecture: As a dedicated component of the Safety Manager platform, it is fully optimized for the system’s safety protocols and fault-handling mechanisms, ensuring compliance with the overall safety certification (e.g., IEC 61508 SIL 3).

Application Cases in Various Fields

- Oil & Gas (Offshore Platforms – ESD/F&G): Forms the communication core of the Safety Manager chassis that executes the Emergency Shutdown and Fire & Gas logic, ensuring reliable data flow between redundant processors and I/O modules reading critical sensors and activating shutdown valves.

- Chemical and Petrochemical Plants: Used in the main safety controller protecting high-pressure reactors and distillation columns, where the integrity of internal module communication is as vital as the field I/O.

- Power Generation (Turbine Protection): Serves in the safety system guarding gas or steam turbines, coordinating between processors that execute overspeed logic and the I/O modules connected to trip solenoids and speed sensors.

- Pharmaceuticals: Provides the fault-tolerant communication backbone in the SIS controlling critical batch processes, where any internal communication failure could compromise safety or product quality.

Comparison with Competing Products

- vs. Standard PLC Backplanes: A standard PLC backplane provides simple electrical connectivity. The SBHM is an active, intelligent communication manager with redundancy, bus arbitration, and advanced diagnostics specifically designed for a fault-tolerant safety system.

- vs. Other Safety System Backbone Components (e.g., Triconex TMR Bus): Competing systems have similar central communication modules. The Honeywell 51403645-100 SBHM is distinguished by its specific integration within the Safety Manager’s Triple Modular Redundant (TMR) or fault-tolerant architecture and its configuration within the Safety Builder engineering toolset.

- vs. Using Ethernet for Internal Module Communication: While some systems use Ethernet internally, the proprietary Safety Bus managed by the SBHM is optimized for deterministic, safety-certified, and noise-immune communication within the constrained environment of a single chassis, offering performance characteristics different from general-purpose Ethernet.

Selection Suggestions and Precautions

- Exact Chassis and System Compatibility: The 51403645-100 SBHM is designed for specific Safety Manager chassis models (e.g., for a specific generation of CPM). Verify compatibility with your exact controller model and chassis part number.

- Mandatory Redundant Configuration: For any operational safety system, the SBHM must be installed as a redundant pair as specified in the Honeywell hardware manual. Operating with a single hub module is not a safe or supported configuration.

- Slot Location is Critical: Install the modules in their designated slots as shown in the chassis layout diagram. Incorrect placement can prevent the system from initializing or compromise redundancy.

- Firmware Version Synchronization: The firmware of the SBHM modules should be compatible with the firmware of the Central Processing Modules (CPMs) and other system components. Always follow Honeywell’s firmware compatibility matrix.

- Monitor System Diagnostics: While the modules have local LEDs, their status is also integrated into the Safety Builder software. Regularly check system diagnostics for any SBHM-related alarms or warnings.

8280-505 DCS

8290-195 DCS

8291-020 UPS

8250-807 DCS

8250-818 DCS

8256-021 DCS

8270-092 DCS

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922