Description

Product Description

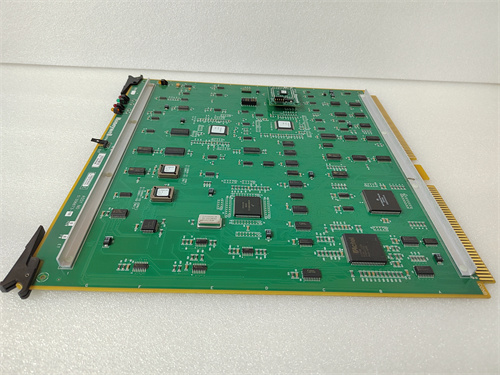

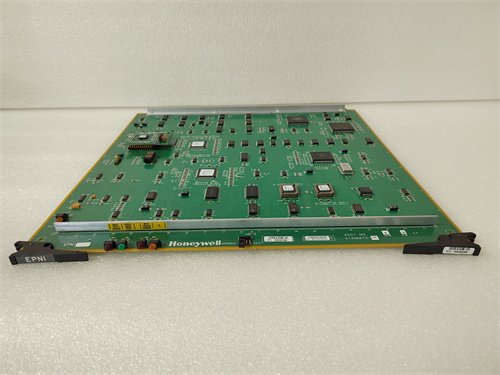

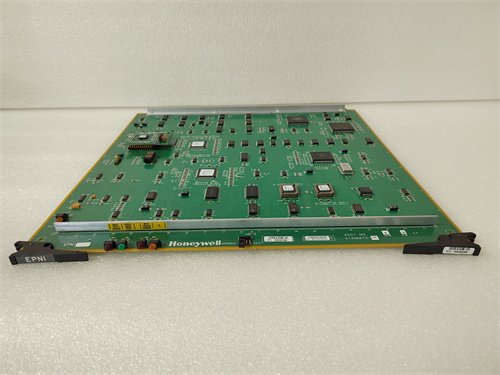

The HONEYWELL 51306673-100 EPNI is a specialized power supply and communication module designed for Honeywell’s Safety Manager series of safety instrumented systems (SIS). This module, identified as an Expander Power and Network Interface (EPNI), serves two critical functions: it provides conditioned and isolated DC power to a Safety Manager expander chassis and acts as the communication gateway between that expander chassis and the main Safety Manager controller. The 51306673-100 EPNI is therefore a fundamental component for building scalable, high-availability safety systems, enabling the extension of I/O capacity beyond the main controller chassis. Integrating the Honeywell 51306673-100 EPNI is essential for creating distributed safety architectures in large process plants.

Product Parameters and Specifications

- Product Type: Expander Power and Network Interface Module.

- Compatible Systems: Honeywell Safety Manager (SM) series safety systems.

- Primary Functions:

- Power Supply: Converts incoming AC power to the regulated DC voltages required by all modules in the expander chassis.

- Network Interface: Manages the high-speed, deterministic communication link (the Safety Network) between the expander chassis and the primary Safety Manager controller.

- Input Power: Typically accepts a wide-range AC input (e.g., 85-264 VAC, 47-63 Hz).

- Output Power: Provides specific DC voltage rails (e.g., +5V, +24V) for the expander chassis backplane.

- Communication: Implements Honeywell’s proprietary Safety Network protocol, which is certified for safety and supports time-synchronized, fault-tolerant data exchange.

- Redundancy Support: Can be installed in a redundant pair (1oo2) within the expander chassis to eliminate it as a single point of failure for both power and communication.

- Hot-Swappable: Designed to be inserted or removed from a powered expander chassis without disrupting the operation of other modules or the safety network, supporting online maintenance.

- Diagnostics: Comprehensive status LEDs and internal diagnostics that report health information to the main Safety Manager controller.

Advantages and Features

- Integrated Power and Communication: The HONEYWELL 51306673-100 EPNI uniquely combines power distribution and safety network interfacing in one module. This simplifies expander chassis design, reduces component count, and ensures synchronized operation between power availability and communication integrity.

- Enables Scalable Safety Architectures: This module is the key component that allows a Safety Manager system to grow beyond a single chassis. It enables the connection of remote I/O expander racks, facilitating a distributed safety system topology that places I/O close to field devices while maintaining central logic execution.

- Fault-Tolerant Design: When deployed in a redundant configuration, the module provides a highly available path for both power and data. The loss of one EPNI module is automatically compensated by its partner, ensuring the expander chassis remains fully operational.

- Certified Safety Communication: The embedded network interface uses a safety-certified protocol designed for deterministic and secure data exchange, which is a mandatory requirement for Safety Instrumented Systems (SIS) to meet IEC 61508 / IEC 61511 standards.

- Enhanced System Diagnostics and Manageability: The module’s health is continuously monitored and reported to the engineering workstation. This centralized view of power and communication status across all expander chassis simplifies system management and troubleshooting.

Application Cases in Various Fields

- Oil & Gas (Offshore Platforms): Used to connect multiple remote expander chassis housing I/O for Emergency Shutdown (ESD) and Fire & Gas (F&G) systems spread across different modules of the platform to a central Safety Manager controller.

- Large Chemical Complexes: Enables a single Safety Manager controller to manage safety I/O distributed across vast plant areas, such as separate reactor buildings, tank farms, and utilities areas, via expander chassis.

- Power Generation (Turbine Islands): Allows the safety system protecting multiple gas turbines or boiler auxiliaries to use a centralized controller with localized I/O expander racks near each turbine.

- Pharmaceutical Plants: Supports safety system architecture where critical I/O for batch reactors and containment areas is located in separate, classified electrical rooms but controlled by a unified safety logic solver.

Comparison with Competing Products

- vs. Using Separate Power Supplies and Communication Cards: Piecing together generic components lacks integration, guaranteed performance, and safety certification. The purpose-built 51306673-100 EPNI ensures optimized interaction between power sequencing and network startup/fault handling.

- vs. Directly Wiring All I/O to a Central Chassis: For large plants, this approach requires massive, expensive cable runs. The EPNI module enables a distributed architecture, drastically reducing wiring costs and improving signal integrity by locating I/O remotely.

- vs. Other Safety System Remote I/O Controllers (e.g., Triconex): Competing systems have their own remote I/O solutions. The Honeywell 51306673-100 EPNI is distinguished by its deep integration with the Safety Manager’s Safety Network, its combined power/communication function, and configuration within the Safety Manager engineering environment.

Selection Suggestions and Precautions

- Verify Exact System Compatibility: The 51306673-100 EPNI is specific to Honeywell Safety Manager expander chassis. Confirm compatibility with your specific Safety Manager controller model, firmware, and expander chassis type.

- Mandatory Redundancy for Critical Applications: For any safety application, the EPNI module should be installed in a redundant (1oo2) pair as per Honeywell’s safety manual. A single module represents a single point of failure for the entire expander chassis.

- Input Power Quality and Backup: Feed the module from a clean, reliable AC source. The use of an Uninterruptible Power Supply (UPS) dedicated to the safety system is a critical best practice to ensure continuous operation.

- Network Topology and Cabling: Adhere strictly to Honeywell’s specifications for the Safety Network cabling (type, length, termination). The performance and safety certification of the entire expanded system depend on a properly installed network.

- Configuration within Safety Builder: The expander chassis and its EPNI module must be correctly configured and addressed within the Honeywell Safety Builder engineering software to be recognized and managed by the main controller.

8250-570

8238-009 DCS

8239-001 DCS

8239-002 DCS

8239-005 DCS

8234-167 DCS

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922