Description

Product Description

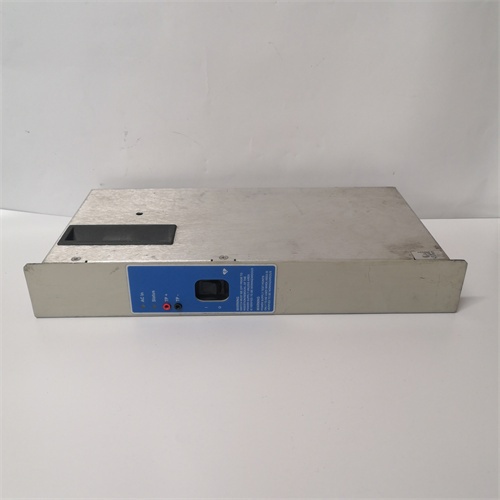

HONEYWELL 51195066-100 / HF-75632-F is a replacement Safety Manager Logic Solver module or a critical FTA (Field Terminal Assembly) module for the Honeywell Safety Manager system. This dual-part-number component is a core hardware element of a high-integrity safety instrumented system (SIS). The primary function of this HONEYWELL module is to execute the certified safety logic that protects a plant or process unit. It receives inputs from safety sensors, processes them through a pre-defined and rigorously tested application program, and drives outputs to final elements (like shutdown valves) to bring the process to a safe state. The 51195066-100 / HF-75632-F is designed for extreme reliability and deterministic response, meeting stringent Safety Integrity Level (SIL) standards. For safety engineers, this module is the central processing unit of a safety loop, and its integrity is non-negotiable.

Product Parameters / Technical Specifications

- Manufacturer: Honeywell

- System: Honeywell Safety Manager (part of the Experion PKS ecosystem)

- Functional Designation: Safety Logic Solver Module or Critical FTA Module.

- Safety Standards: Compliant with IEC 61508 and IEC 61511 for functional safety. Typically certified for use in SIL 2 or SIL 3 applications.

- Architecture: Likely part of a redundant (1oo2D) or fault-tolerant architecture to ensure high availability and safety.

- Processor: Features a dedicated, high-integrity processor for executing safety logic.

- Memory: Contains both volatile and non-volatile memory for the operating system and the safety application.

- Diagnostics: Extensive continuous self-diagnostics and hardware watchdog timers to detect and respond to internal faults within milliseconds.

- Communication: Interfaces with the Safety Manager network and engineering stations via proprietary, secure protocols. The HF-75632-F designation often refers to a specific FTA that provides the physical I/O interface.

- Certification: TÜV or exida certified for use in safety applications.

Advantages and Key Features

- Certified Safety Performance: The primary advantage of the HONEYWELL 51195066-100 is its pre-certified design for functional safety, reducing the validation burden on the end-user and ensuring a proven architecture.

- High Availability & Fault Tolerance: Designed with redundancy and diagnostics to ensure the system remains operational (or fails safely) even in the event of a single hardware failure, which is critical for safety systems.

- Deterministic, High-Speed Response: Provides guaranteed, millisecond-level response times for executing safety logic and initiating shutdown sequences.

- Integrated with Experion PKS: Offers seamless integration with Honeywell’s Experion DCS for operator visibility, alarm management, and historical data collection, while maintaining physical and logical separation for safety integrity.

- Comprehensive Lifecycle Support: Supported by Honeywell’s Safety Builder engineering tool for configuration, simulation, and documentation, covering the entire safety lifecycle.

- Robust Physical Design: Built to withstand industrial environmental conditions with a high degree of immunity to electromagnetic interference (EMI).

Application Cases in Industry

- Emergency Shutdown (ESD) Systems: Used in oil & gas production platforms, pipelines, and refineries to execute shutdown logic for fires, gas leaks, or overpressure events.

- Burner Management Systems (BMS): Provides the safety logic for fuel trains and combustion control in furnaces and boilers to prevent explosions.

- Turbomachinery Control (TMC): Protects critical rotating equipment like compressors and turbines from damage due to overspeed, high vibration, or lubrication failure.

- Fire & Gas (F&G) Systems: Processes inputs from gas detectors and flame detectors to initiate alarm and mitigation actions.

Comparison with Competing Products

| Feature | HONEYWELL 51195066-100 (Safety Manager) | Standard PLC used for Safety (e.g., with a Safety Option) |

|---|---|---|

| Design Philosophy | Dedicated Safety System: Hardware and software are designed from the ground up for safety, with inherent fault detection and tolerance. | Adapted Control System: A standard PLC platform with added safety-related features and software. |

| Certification Basis | System Certification: The entire platform (hardware, OS, compiler) is certified as a safety system. | Component/Software Certification: Often, only the safety CPU and runtime software are certified; the engineering station and other components may not be. |

| Failure Mode & Diagnostics | Predictable Safe State: Failures are designed to drive the process to a predefined safe state. Diagnostics are extensive and hardware-based. | Relies on Programmed Diagnostics: Safe state behavior depends more on user-programmed logic and diagnostics. |

| Separation of Control & Safety | Inherent Physical & Logical Separation: Maintains clear separation from the basic process control system (BPCS). | Can be Integrated: Often resides in the same rack or uses the same network as the standard control PLC, requiring careful engineering to ensure separation. |

Selection Suggestions and Precautions

- Safety System Expertise is Mandatory: Selection and replacement of the HONEYWELL 51195066-100 / HF-75632-F must be performed by personnel trained and authorized to work on the Safety Manager system. This is not standard maintenance.

- Exact Part Number Verification is Critical: The dual part number must match exactly. This module is specific to a hardware series and firmware version. Using an incorrect module can compromise the safety certification and system operation.

- Safety Application Backup: Before any handling, a verified and current backup of the safety application logic must be secured from the engineering workstation. The module contains the safety application, and loss of this program is catastrophic.

- Strict Procedures for Replacement: Follow the Safety Manager system’s specific Lockout-Tagout (LOTO) and module replacement procedures. These systems are often live and redundant; incorrect removal can cause a nuisance trip or, worse, inhibit the safety function.

- Observe ESD and Handling Precautions: Treat the module as a highly sensitive electronic device. Use an ESD wrist strap and handle it by the edges. Do not touch connectors or components.

- Sourcing from Authorized Safety Channels: This component is critical to human and asset safety. It must be sourced only from Honeywell directly or from authorized, certified Honeywell Safety System distributors who can guarantee the part’s authenticity, revision level, and provide full traceability. Do not source from the general surplus market.

P0700AH-FOXBORO

P0700FV-FOXBORO

P0700FW-FOXBORO

P0700HE-FOXBORO

P0700TT-FOXBORO

P0700WB-FOXBORO

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922