Description

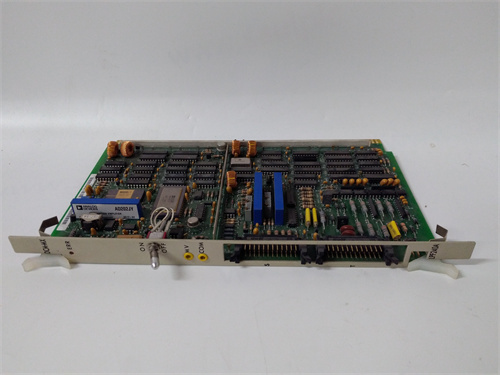

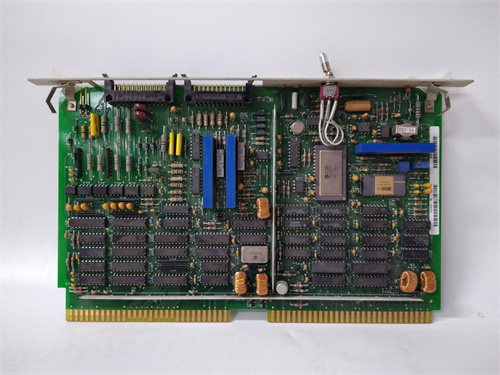

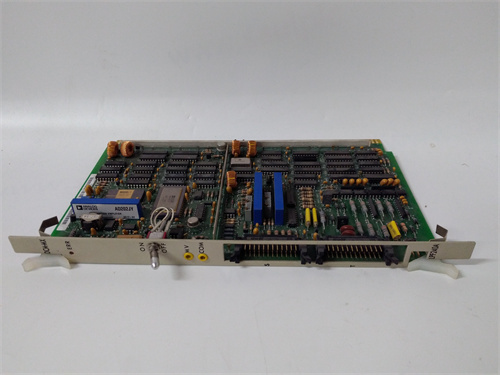

Product Description

The HITACHI LPP100A is a specialized power supply module commonly associated with Hitachi’s industrial automation and control systems, particularly those used in variable frequency drives (VFDs) and elevator/motion control applications. While specific documentation for this exact part number can be challenging to find due to its proprietary nature, the HITACHI LPP100A is generally a critical internal board responsible for generating the low-voltage DC power required to operate the control logic, gate driver circuits, and sensors within a larger power electronics unit. The HITACHI LPP100A ensures that the sensitive control electronics receive clean, stable, and isolated power from the main high-voltage DC bus or AC input. For maintenance technicians servicing Hitachi drives or control systems, identifying and sourcing a genuine HITACHI LPP100A is essential for restoring reliable operation. Technical support and sourcing information for this component can be accessed at [Insert Link Here].

Product Parameters

- Product Type: Power Supply Module / Low-Voltage Power Supply (LVPS) Board

- Common Application: Internal component of Hitachi Variable Frequency Drives (e.g., SJ series, L100 series) or other Hitachi power control units.

- Input Voltage: Typically derives power from the drive’s internal DC bus (e.g., ~300-800 VDC) or from a separate auxiliary AC input (e.g., 220V AC).

- Output Voltages: Provides multiple, isolated DC output rails required by the drive’s electronics, such as:

- +5 VDC or +3.3 VDC for microprocessor logic.

- ±15 VDC for analog circuitry and op-amps.

- +24 VDC for gate driver circuits, sensors, and external control interfaces.

- Power Rating: Has a specific wattage rating to supply all necessary control circuits.

- Protection Features: Likely includes safeguards against overvoltage, overcurrent, and short circuits on its outputs.

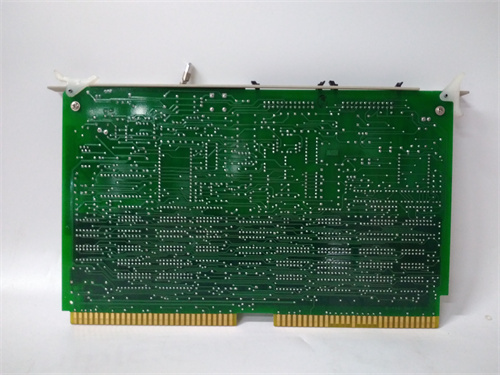

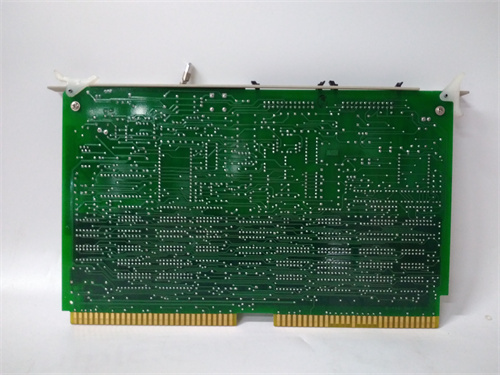

- Form Factor: A printed circuit board (PCB) designed to mount in a specific location within the drive’s chassis, often connected via wiring harness or terminal blocks.

- Cooling: May be passively cooled or require a heat sink, depending on the power dissipation.

Advantages and Features

- Critical for System Operation: The HITACHI LPP100A is a foundational component; without it, the drive’s control logic cannot function, rendering the entire unit inoperable.

- Noise Isolation and Stability: Designed to provide stable voltage rails with low electrical noise, which is crucial for the reliable operation of the drive’s microprocessor, communication chips, and sensitive current/voltage feedback circuits.

- High Reliability: Uses quality components designed for the long-term, continuous operation expected in industrial drive applications.

- Compact and Integrated Design: Engineered to fit precisely within the drive’s mechanical enclosure, optimizing space and ensuring proper thermal and electrical integration.

- Safety Isolation: Provides necessary isolation between the high-voltage DC bus and the low-voltage control circuits, a critical safety requirement.

- Proprietary Compatibility: As a genuine HITACHI LPP100A module, it is guaranteed to match the electrical and mechanical specifications of the original equipment, ensuring compatibility and proper performance.

Application Cases in Key Fields

- Industrial Motor Control: Serving as the control power source inside Hitachi variable frequency drives controlling pumps, fans, conveyors, and compressors in manufacturing and HVAC systems.

- Elevator and Escalator Control: Used within the drive or controller cabinets of Hitachi vertical transportation systems to power the control logic and interface boards.

- Railway/Transportation: Possibly used in auxiliary power supplies or traction control systems manufactured by Hitachi.

- Energy and Infrastructure: Incorporated into Hitachi-made systems for power conditioning, solar inverters, or uninterruptible power supplies (UPS).

- Factory Automation: Powering the internal electronics of Hitachi servo drives or programmable logic controllers within production lines.

Comparisons with Competing Products

The HITACHI LPP100A is unique to Hitachi’s internal designs. Its functional equivalents are power supply boards within other drive manufacturers’ products:

- Vs. ABB / ACS Drive Power Supply Boards (e.g., SDCS-PIN-51): Both serve the same core function but are mechanically and electrically different, designed for their respective drive platforms.

- Vs. Siemens SINAMICS Power Supply Modules (e.g., in the CU320): Siemens integrates its power supply differently. The HITACHI LPP100A is specific to Hitachi’s component layout and voltage requirements.

- Vs. Yaskawa / Mitsubishi Internal LVPS Boards: Other Japanese drive manufacturers have their own proprietary designs. They are not interchangeable.

- Vs. Generic Switched-Mode Power Supplies (SMPS): While a generic SMPS could provide similar voltage rails, it would lack the specific form factor, mounting, connector interfaces, and most importantly, the design validation for the electromagnetic environment inside a high-power drive. Using a non-OEM part risks reliability and safety.

Selection Suggestions and Precautions

- Selection Advice:

- Exact Part Number Matching is Paramount: The part number HITACHI LPP100A must be matched exactly. Verify the code on the faulty board. Even slight variations (e.g., LPP100A-1, LPP100B) indicate a different revision or variant.

- Identify the Host Equipment: Determine the exact model of the Hitachi drive or control unit from which the board was removed (e.g., Hitachi SJ700, L100-A55U). This is critical for sourcing the correct part.

- Visual Inspection and Documentation: Before removing the old board, take clear photographs of its connections, orientation, and any jumper settings. Note the colors and positions of all wiring harnesses.

- Source from Specialized Suppliers: Purchase from authorized Hitachi distributors or from highly reputable industrial electronic repair specialists who can test the board and guarantee compatibility.

- Important Precautions:

- High Voltage Hazard: The power supply board is inside equipment with lethal high voltages. Ensure the entire unit is powered off, disconnected, and that the main DC bus capacitors are fully discharged (using a safe discharge procedure) before attempting any work.

- Electrostatic Discharge (ESD): The board contains static-sensitive components. Handle it with proper ESD precautions (wrist strap, anti-static mat).

- Observe Torque Settings: When reconnecting terminal screws, use the specified torque to prevent damage to the PCB or creating a high-resistance connection that can overheat.

- Check for Secondary Failures: A failed HITACHI LPP100A is often a symptom of another problem (e.g., a shorted IGBT module, water ingress). Before installation, inspect the drive for other damaged components (burnt resistors, bulged capacitors) to prevent immediate failure of the new board.

- Perform Functional Test: After installation, perform a careful power-up test, preferably with a current-limited power source initially, to verify the new board operates correctly before applying full power to the drive.

P62400161161-FOXBORO

P77440H3N000-FOXBORO

P77440H3N300-FOXBORO

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922